A non-screw self-feeding ball pressing machine

A non-screw and briquette machine technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of reducing the ball forming rate and ball quality, unreasonable blanking, and large electric energy, so as to save electric energy Consumption, stable rotation, and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

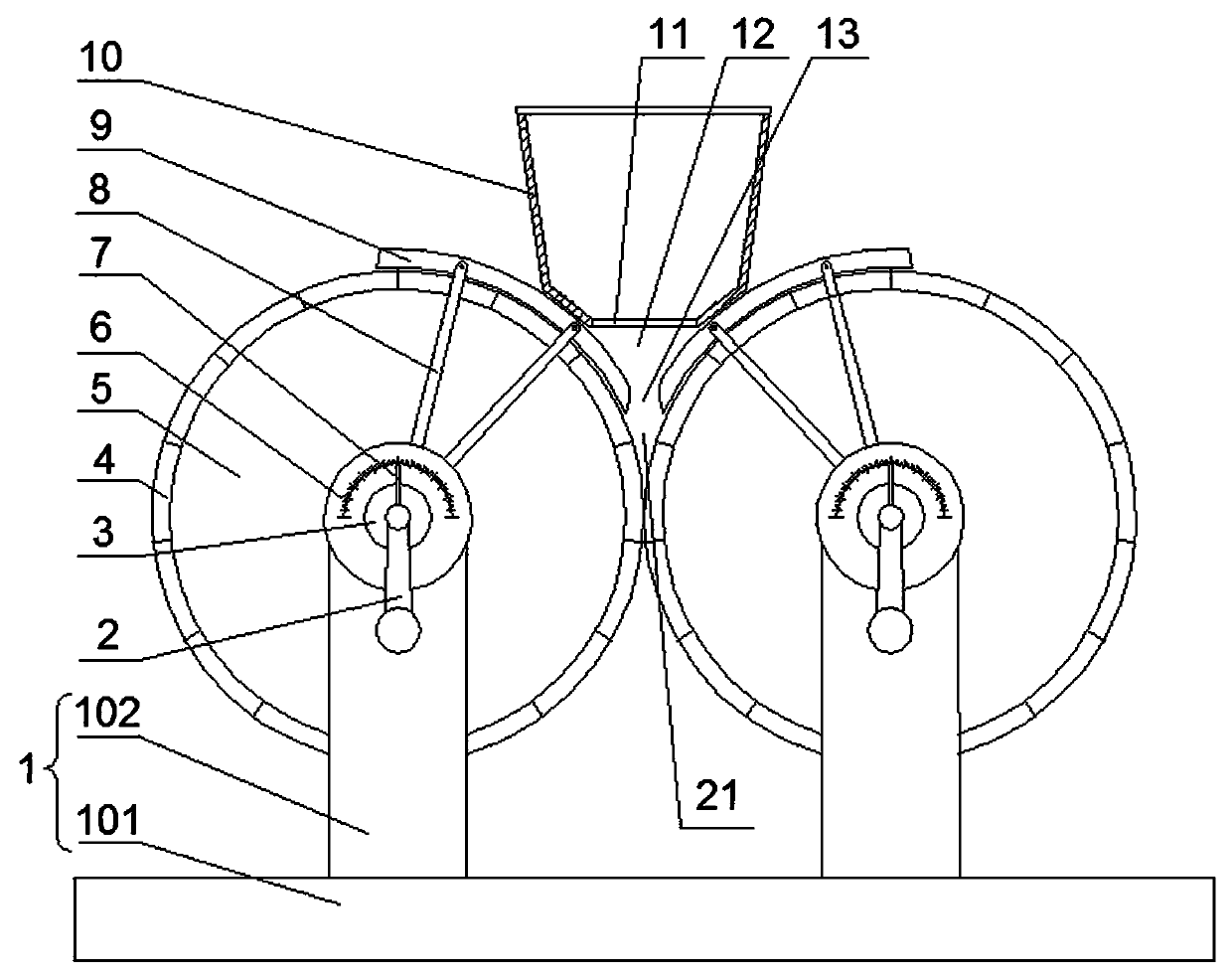

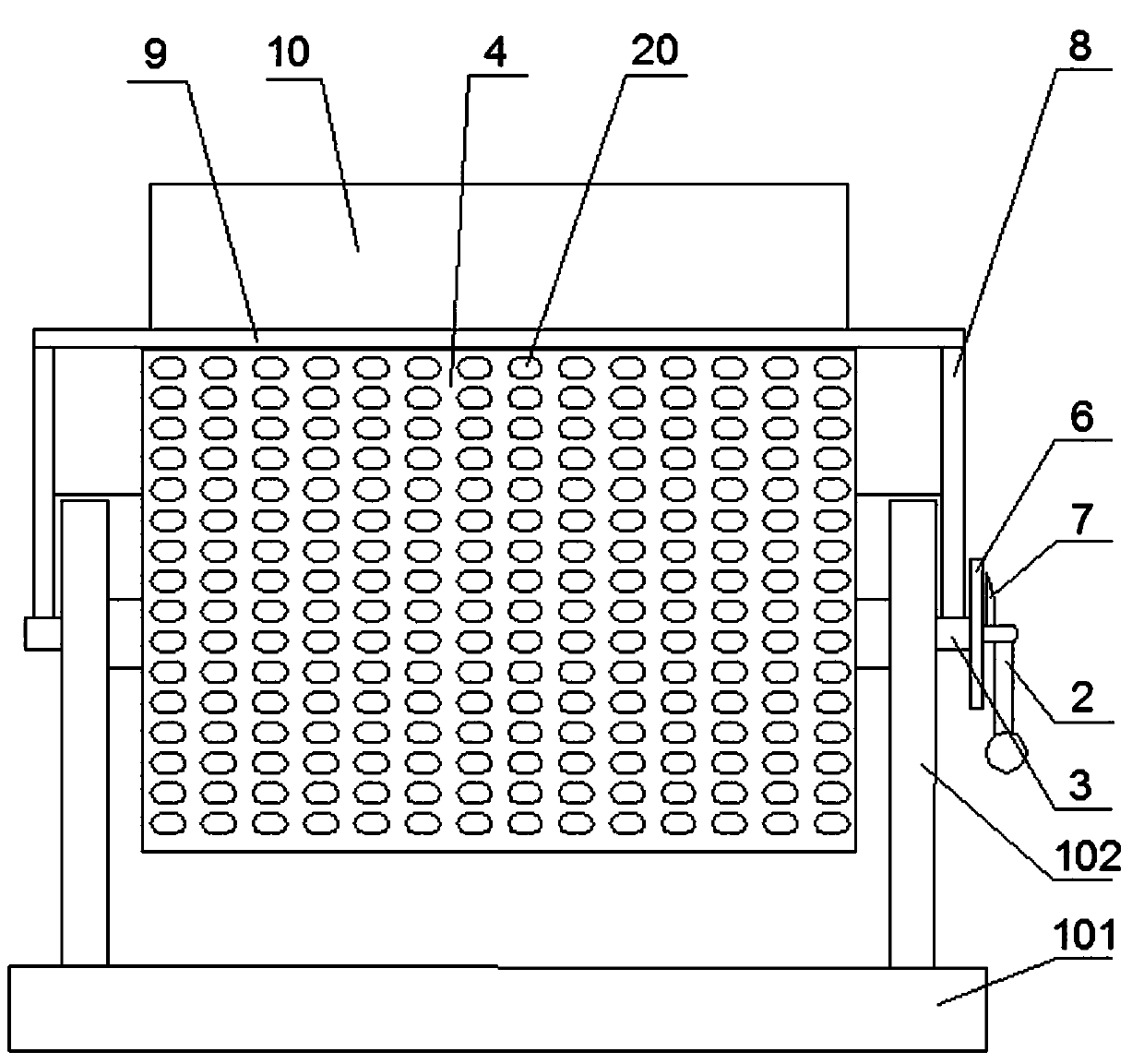

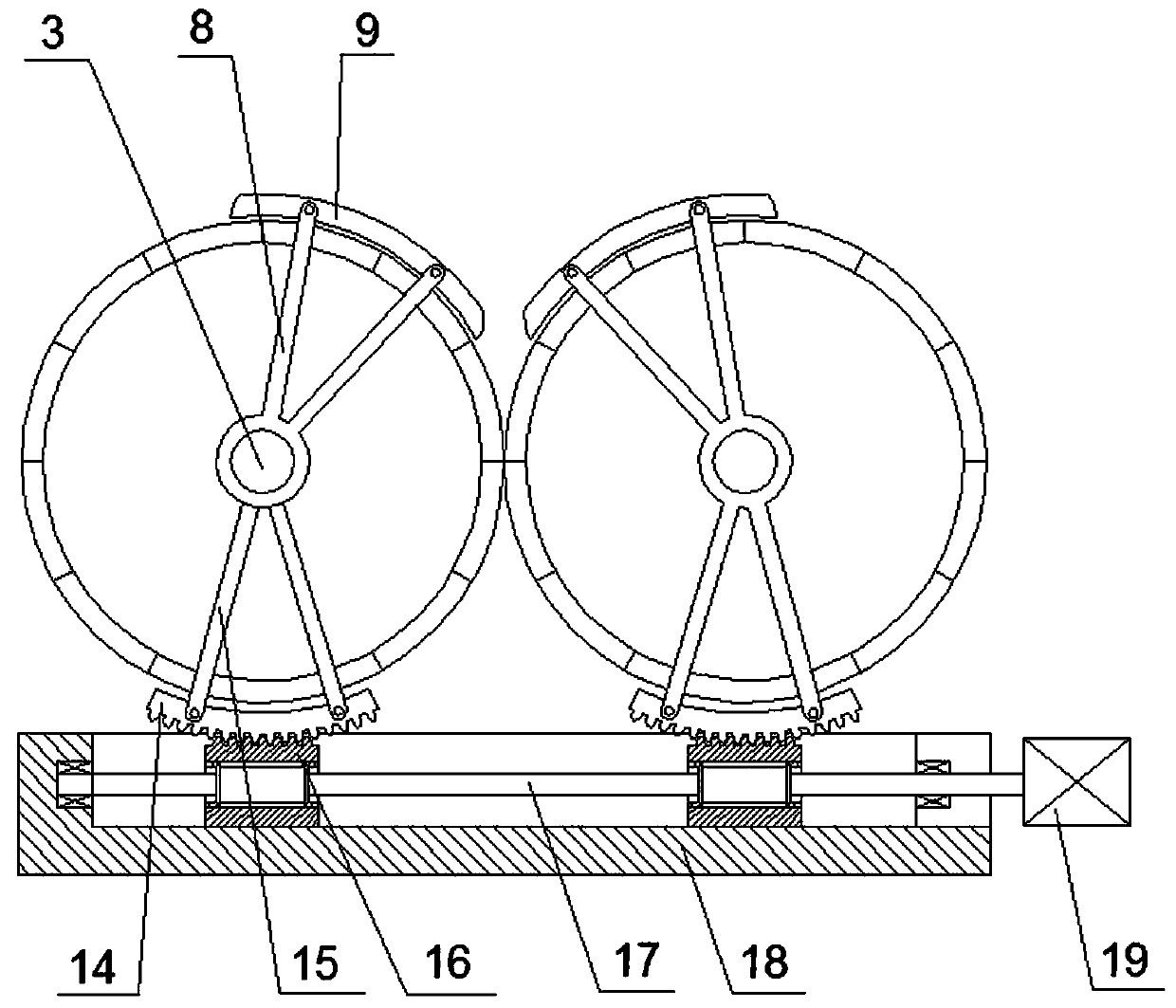

[0022] Embodiment one, such as figure 1 and figure 2 As shown, a kind of non-screw self-feeding briquetting machine of the present embodiment is the same as the briquetting machine in the prior art, and both include a frame 1 made up of a base 101 and a bracket 102 and a frame 1 arranged in parallel on the bracket 102. Two pressure ball rollers 5. A plurality of hemispherical cavities 20 for pressing coal powder into briquettes are correspondingly provided on the roller skins 4 of the two briquetting rollers 5 . During the synchronous rotation of the left pressure ball roller 5 clockwise and the right pressure ball roller 5 counterclockwise by the driving mechanism, a ball forming area 21 is formed above the line connecting the centers of the two pressure ball rollers 5. After entering into the ball zone 21, it is filled into the hemispherical forming cavity 20 and is gradually compacted until the corresponding two hemispherical forming cavity 20 are completely matched and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com