Welding positioning machine for reinforcement cage

A welding positioner and reinforcement cage technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of laborious rotation at the end of the main reinforcement, poor rotation, unbalanced force at the end, etc., to achieve improved The Effect of Stirrup Wrap Binding and Welding Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

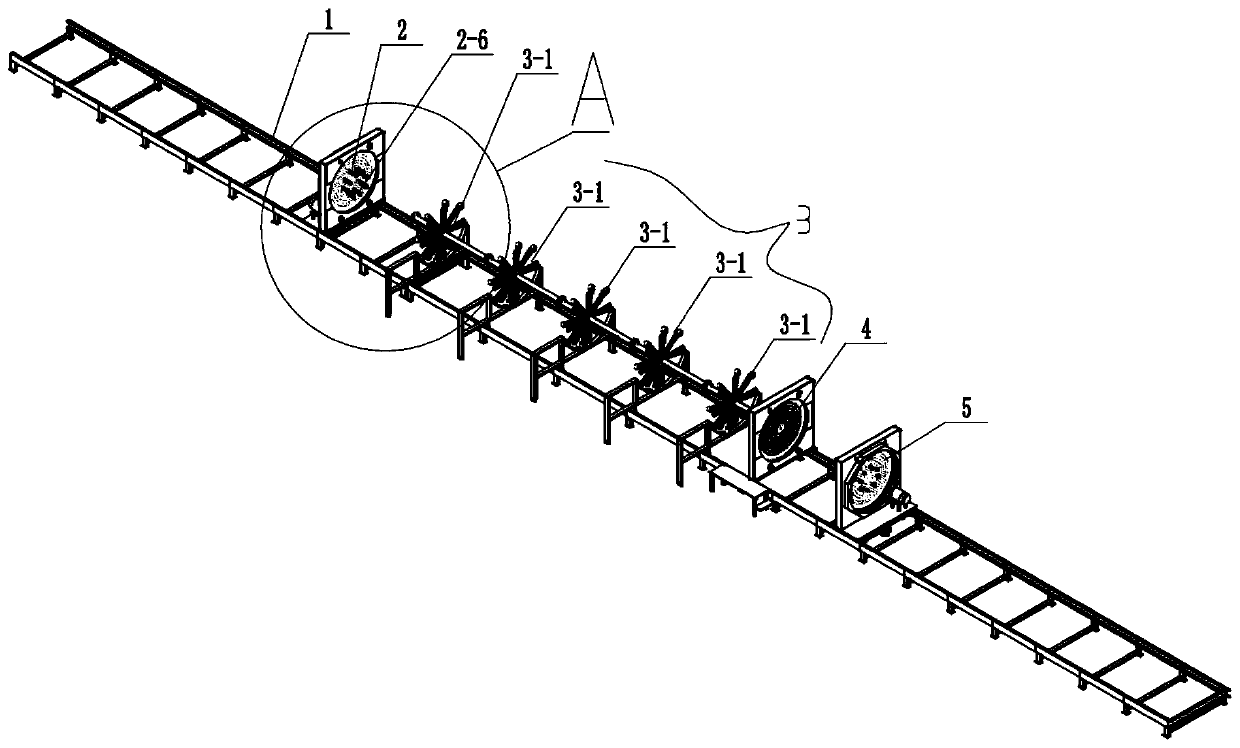

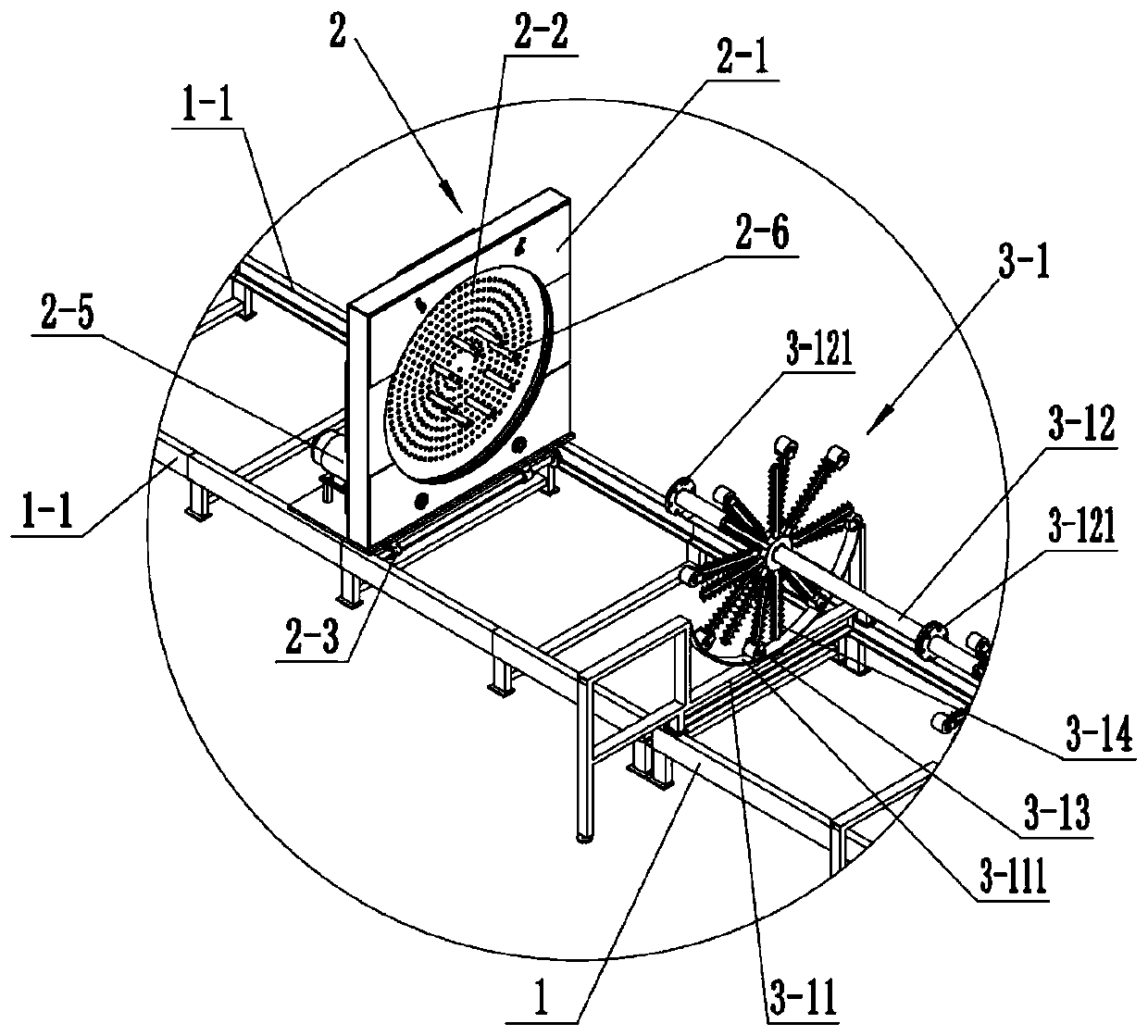

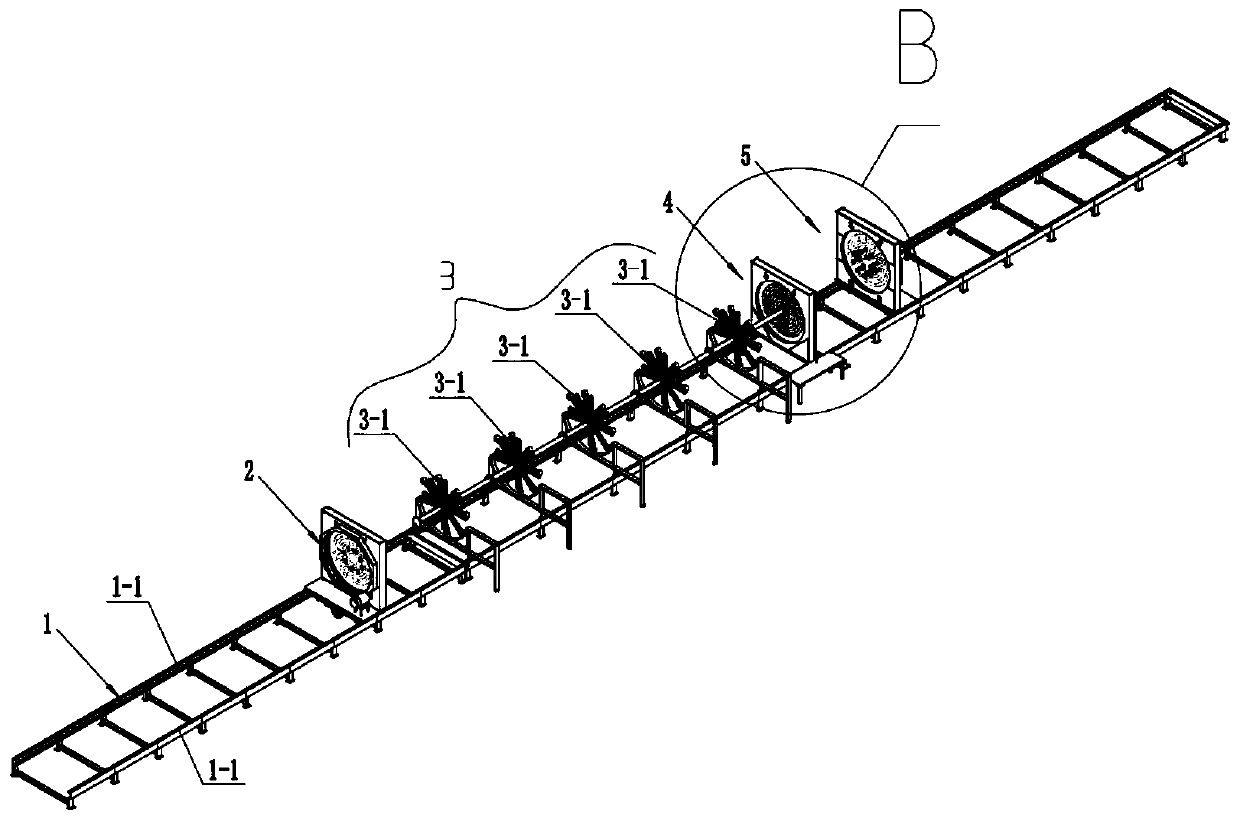

[0036] Example: see Figure 1-4 , a steel cage welding positioner, which includes a horizontal track 1, a main bar tail end traction rotation device 2, a main bar rotation support device 3, a main bar rotation positioning device 4 and a main bar head end traction rotation device 5.

[0037] Wherein, the tail-end traction and rotation device 2 of the main bars is used to drive the tail-ends of several main bars to be pulled forward to feed materials or / and drive the tail-ends of several main bars to perform circumferential rotation during steel cage welding.

[0038] Wherein, the main reinforcement rotating support device 3 is used for supporting the sections to be welded of each several main reinforcements when the reinforcement cage is welded, so as to prevent the displacement or deformation of several main reinforcements from affecting the stability of the shape and structure of the reinforcement cage. Rotation supporting device 3 can follow rotation.

[0039] Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com