Macroporous hybrid material and preparation method thereof

A hybrid material and pore volume technology, applied in chemical instruments and methods, inorganic chemistry, refined hydrocarbon oil, etc., to achieve high desulfurization rate, improve diffusion, and improve adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the mass fraction of copper nitrate, nickel nitrate, zinc nitrate and aluminum nitrate in the solution is 13.7wt%, 4.1wt%, 3.7wt%, 3.2wt%, weigh the raw materials and add ternary solvent (water 3 wt%-ethanol 25 wt%) %-N,N-dimethylformamide 72wt%), after stirring at 50°C to dissolve it completely, adjust the pH value of the solution to 6; secondly, add 0.23wt% cetyl trimethyl bromide Ammonium was used as a template, and 0.11wt% of 3-mercaptopropyltrimethoxysilane was added as a mercapto modifier, and mixed evenly; then, a ternary complexing agent (2,5-dihydroxy-terephthalic acid 9.0 wt%-terephthalic acid 11.1wt%-trimellitic acid 79.9wt%) was added to the solution, stirred rapidly to make it evenly mixed, and then the solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, at 100 Crystallization at ℃ for 16h. After the crystallization, the product was washed with acetone for 5 times, and suction-filtered, and the fil...

Embodiment 2

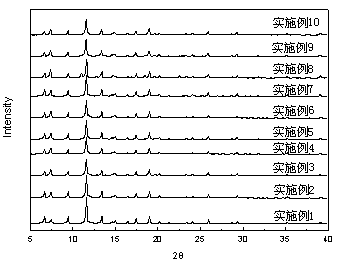

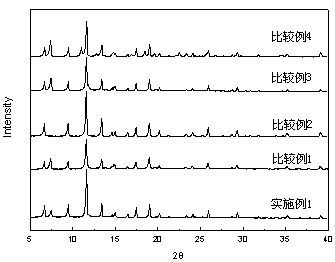

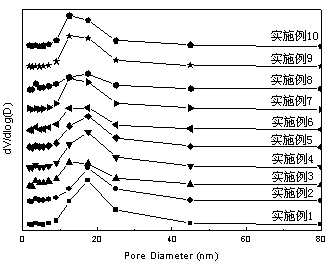

[0033] The preparation method is the same as in Example 1, except that the ternary solvent is water 1 wt%-ethanol 30 wt%-N,N-dimethylformamide 69wt%; the template is sodium dodecylbenzenesulfonate, The dosage is 0.42%; the thiol modifier is mercaptoacetic acid, the dosage is 0.21%; the crystallization temperature is 120°C, the crystallization time is 18h, the drying temperature is 160°C, and the drying time is 20h. Prepared A2# sample with a pore volume of 0.817 cm 3 / g, XRD spectrum, the relative intensity I / I of each diffraction peak 0 , and the average pore size distribution are listed in figure 1 , Table 1 and image 3 middle.

Embodiment 3

[0035] The preparation method is the same as in Example 1, except that the ternary solvent is water 5wt%-ethanol 10wt%-N,N-dimethylformamide 85wt%; the template agent is dodecylamine, and the dosage is 0.89%; The active agent is methyl thioglycolate, the dosage is 0.45%; the crystallization temperature is 140°C, the crystallization time is 12h, the drying temperature is 180°C, and the drying time is 16h. Prepare A3# sample, the pore volume is 0.810cm 3 / g, XRD spectrum, the relative intensity I / I of each diffraction peak 0 , and the average pore size distribution are listed in figure 1 , Table 1 and image 3 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com