System and method for lowering HCL content in pickling flue gas

A flue gas and pickling technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high acid consumption, increased burden on 301 water treatment station, unstable pickling quality, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

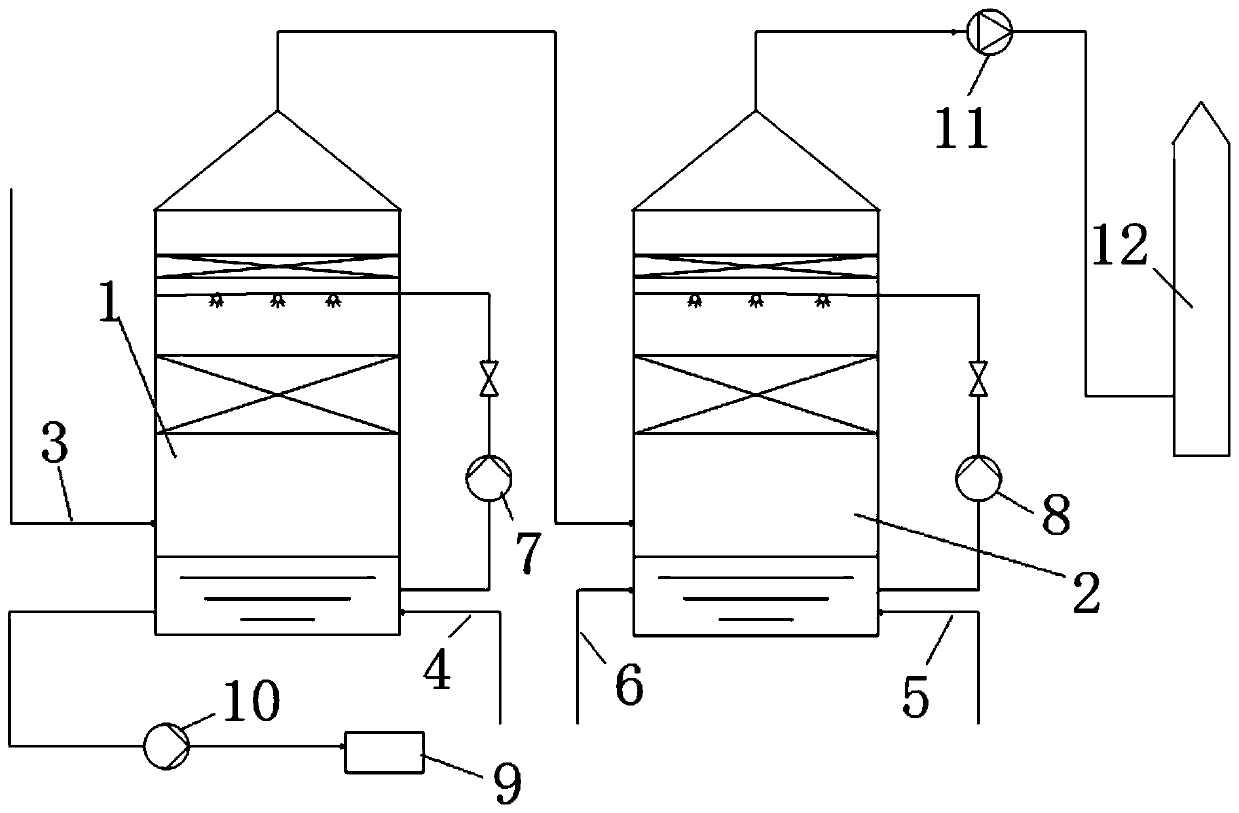

[0032] Such as figure 1 As shown, a system for reducing the content of HCL in pickling flue gas includes a first-stage acid mist purification tower 1 for primary purification of the introduced flue gas and a second-stage acid mist purification tower for treating the first-stage acid mist purification tower. Secondary acid mist purification tower 2 for secondary purification, the system for reducing the HCL content in pickling flue gas also includes a replenishment delivery mechanism for circulating water to the first acid mist purification tower and secondary acid mist purification tower respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com