A scale-removing and anti-scaling alloy, a scale remover and a preparation method thereof

A descaler and alloy technology, applied in the field of alloys, can solve problems that are contrary to environmental protection and sustainable development, and have not been well resolved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

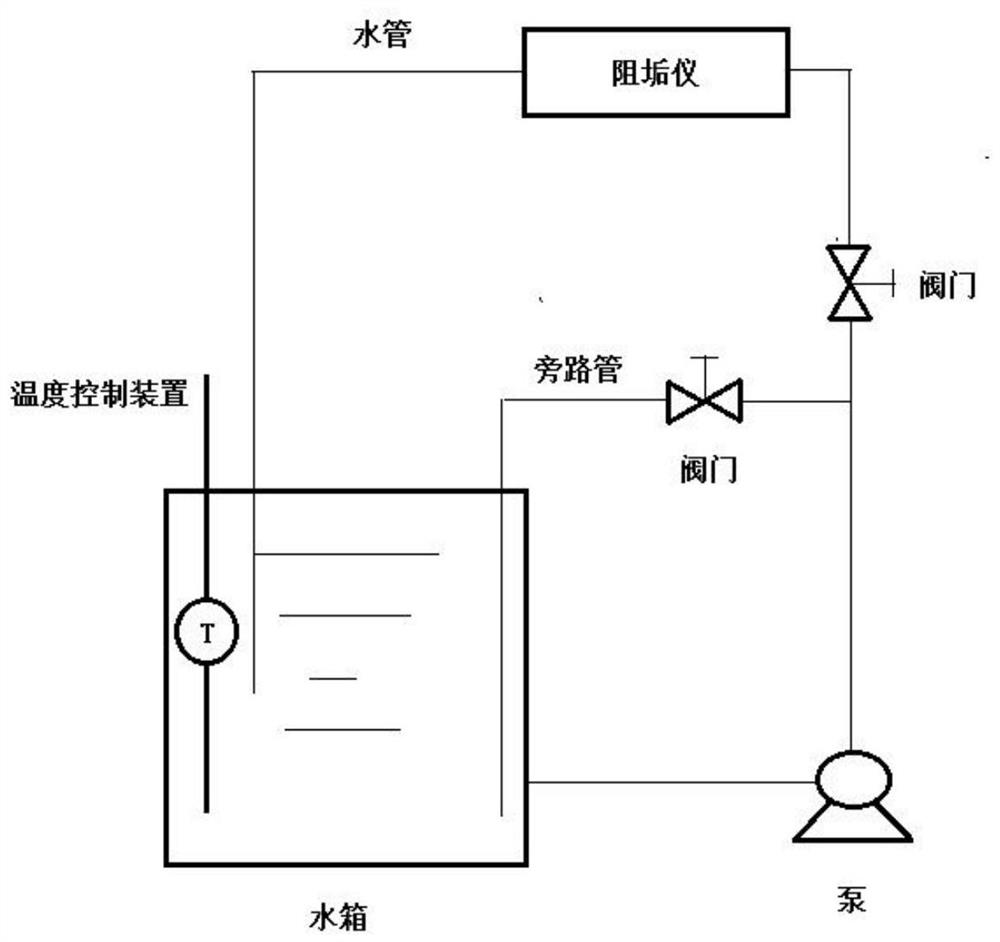

Image

Examples

Embodiment 1

[0047] Embodiment 1: Descaling and anti-scaling alloy

[0048] 1. In terms of mass percentage, the scale-removing and anti-scaling alloy of the present embodiment is composed of the following components:

[0049] Copper 73.54%, nickel 7.58%, tin 1.66%, zinc 10.63%, lead 6.59%.

[0050] 2. A descaling device made of the descaling and anti-scaling alloy.

[0051] 3, the preparation method of described scale remover comprises the steps:

[0052] Step 1. According to the different melting points of various metals, first put nickel and copper into the furnace in proportion to heat to 1350°C-1380°C to fully melt and mix nickel and copper, and then lower the temperature to 800°C to put tin and lead Put it in and melt it, keep it for 3 minutes after the tin and lead are fully melted, then add zinc and stir to melt;

[0053] Step 2. After the zinc is melted, the temperature is raised to 1250°C to start pouring;

[0054] Step 3: The poured and molded material is then lathe processed...

Embodiment 2

[0055] Embodiment 2: Scale-removing and anti-scaling alloy

[0056] 1. In terms of mass percentage, the scale-removing and anti-scaling alloy of the present embodiment is composed of the following components:

[0057] Copper 71%, nickel 6%, tin 0.5%, zinc 12.5%, lead 10%.

[0058] 2. A descaling device made of the descaling and anti-scaling alloy.

[0059] 3, the preparation method of described scale remover comprises the steps:

[0060] Step 1. According to the different melting points of various metals, first put nickel and copper into the furnace in proportion to heat to 1350°C-1380°C to fully melt and mix nickel and copper, and then lower the temperature to 800°C to put tin and lead Put it in and melt it, keep it for 3 minutes after the tin and lead are fully melted, then add zinc and stir to melt;

[0061] Step 2. After the zinc is melted, the temperature is raised to 1250°C to start pouring;

[0062] Step 3: The poured and molded material is then lathe processed, sli...

Embodiment 3

[0063] Embodiment 3: Scale-removing and anti-scaling alloy

[0064] 1. In terms of mass percentage, the scale-removing and anti-scaling alloy of the present embodiment is composed of the following components:

[0065] Copper 75%, nickel 10%, tin 3%, zinc 5%, lead 7%.

[0066] 2. A descaling device made of the descaling and anti-scaling alloy.

[0067] 3, the preparation method of described scale remover comprises the steps:

[0068] Step 1. According to the different melting points of various metals, first put nickel and copper into the furnace in proportion to heat to 1350°C-1380°C to fully melt and mix nickel and copper, and then lower the temperature to 800°C to put tin and lead Put it in and melt it, keep it for 3 minutes after the tin and lead are fully melted, then add zinc and stir to melt;

[0069] Step 2. After the zinc is melted, the temperature is raised to 1250°C to start pouring;

[0070] Step 3: The poured and molded material is then lathe processed, sliced a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com