Temperature-resisting and salt-resisting self-adhesion emulsion temporary blocking acidification diverting agent and preparation method thereof

A temperature-resistant, salt-resistant, acid-steering technology, used in chemical instruments and methods, drilling compositions, etc., can solve the problems of limited self-viscosifying ability, low emulsion viscosity value, and reduced temporary blocking ability, etc. The effects of a wide temperature and salinity range, low initial viscosity, and high injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of temperature-resistant and salt-resistant self-viscosifying emulsion temporary plugging acidification diverting agent:

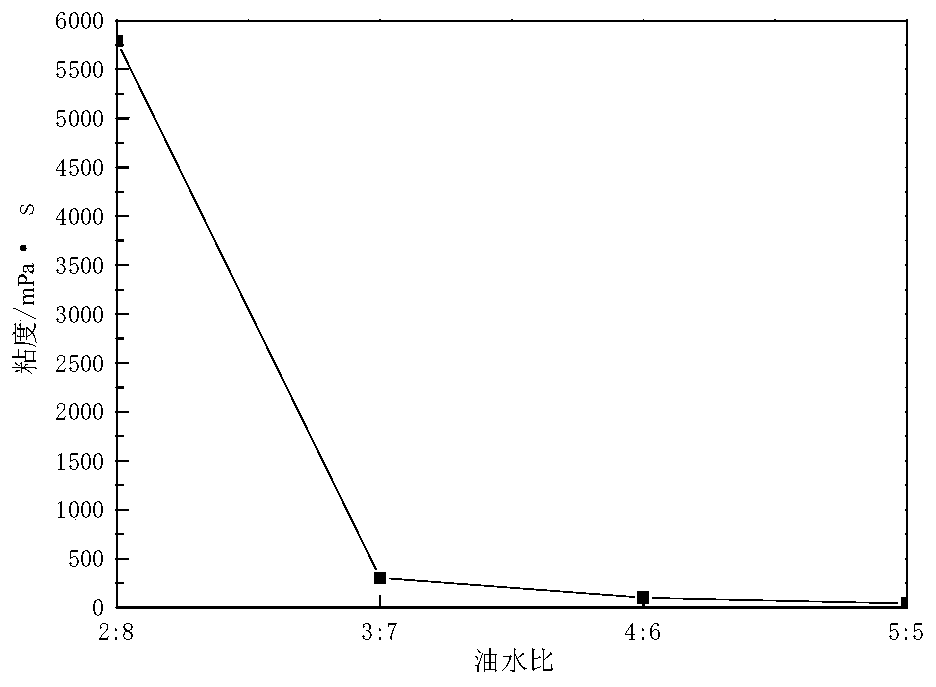

[0033] Weigh 10g, 15g, 20g, and 25g of diesel oil respectively, dissolve 1g of oleic acid diethanolamide and 0.2g of polyisobutylene succinimide in the diesel oil, and stir to disperse them evenly; weigh 40g, 35g, 30g, and 25g to remove Ionized water, dissolve 0.1g sodium dodecylbenzene sulfonate in deionized water, and disperse evenly; according to the combination of oil-water ratio 2:8, 3:7, 4:6, 5:5, the active oil is rotated at 2000r / min Under stirring, add active water drop by drop to form a water-in-oil emulsion. Use SNB-2 viscometer to measure 95°C, 170s -1 The viscosity of different oil-water ratio emulsions is shown in Table 1.

[0034] Table 1

[0035] oil to water ratio

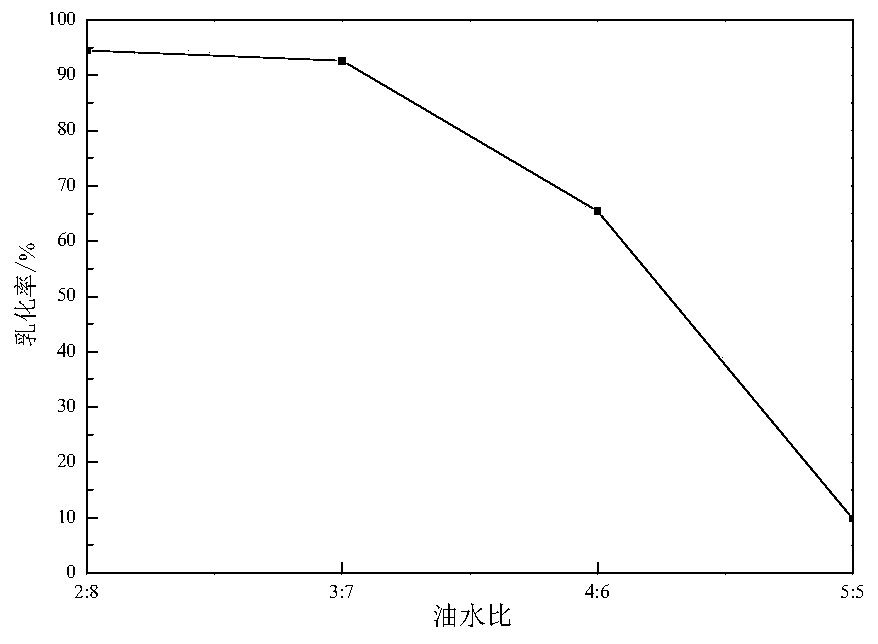

[0036] The emulsion prepared above was aged at 200°C for 6 hours, and the emulsification rate results are shown in Table 2.

[0037] Table 2

...

Embodiment 2

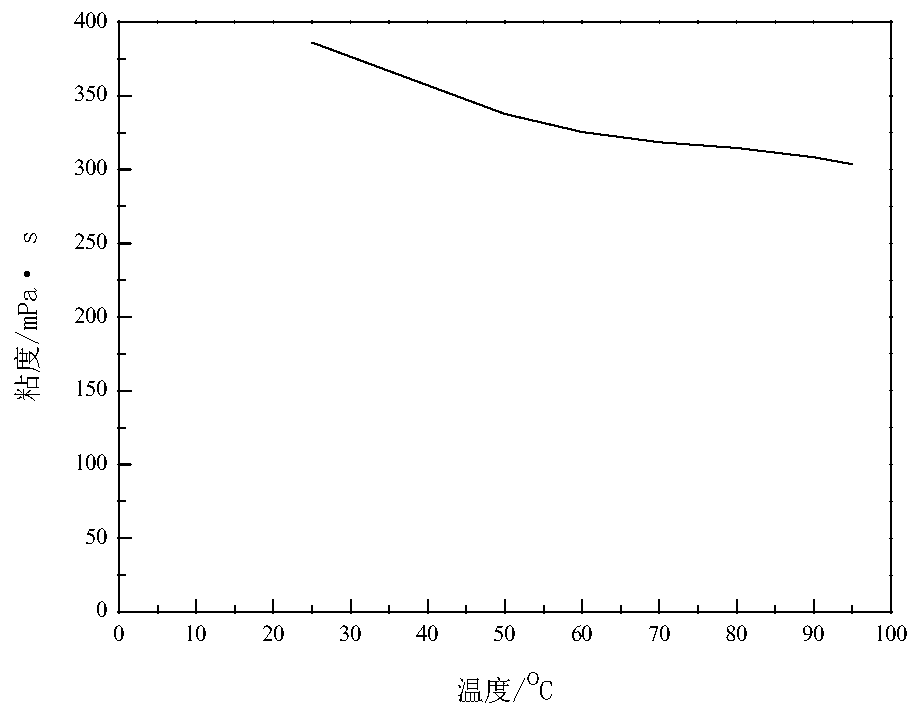

[0041] Weigh 15g of diesel oil, dissolve 1g of oleic acid diethanolamide and 0.2g of polyisobutylene succinimide in diesel oil, and stir to make them uniformly dispersed; weigh 35g of deionized water, and dissolve 0.15g of dodecane in deionized water Sodium phenyl sulfonate, evenly dispersed; stir the active oil at 2000r / min, add active water drop by drop to form a water-in-oil emulsion. Use SNB-2 viscometer to measure 170s -1 The viscosity of the emulsion at different temperatures, the measurement results are shown in Table 3.

[0042] table 3

[0043] temperature / ℃

[0044] From Table 3 and image 3 It can be seen that the viscosity of the emulsion decreases with increasing temperature. Since the SNB-2 viscometer used is heated by a water bath, the temperature can be stabilized at 95°C under laboratory conditions. When the temperature is higher than 60°C, the viscosity decrease rate of the temporary plugging agent slows down, and when the temperature reaches 95...

Embodiment 3

[0046] Using the emulsion temporary blocking acidification diverting agent prepared in Example 2, the diverting agent was aged at 200°C for 30 minutes at high temperature, and then the rheological properties were measured at 95°C. The results are shown in Table 4.

[0047] Table 4

[0048]

[0049] From Table 4 and Figure 4 It can be seen that the viscosity of the emulsion decreases with the increase of rotational speed. When the rotational speed is higher than 30r / min, the viscosity decrease rate of the emulsion slows down and finally tends to be stable; when the rotational speed is 10r / min, the viscosity is as high as 879mPa s, and when the rotational speed increases to 99.9r / min, the viscosity drops to 215mPa s, that is, under the condition of high temperature and high shear rate, the viscosity of the emulsion is low and has good pumping ability; after the emulsion enters the formation, as the injection radius increases, the shear rate decreases and the viscosity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com