Preparation method and application of high strength and porous structure polyvinyl alcohol-gallotannic acid hydrogel

A technology of polyvinyl alcohol and porous structure, which is applied in the field of cartilage repair and biomaterials, can solve the problems of complex preparation process, material toxicity, pore structure, etc., and achieve the effect of simple operation, stable properties and solving both problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

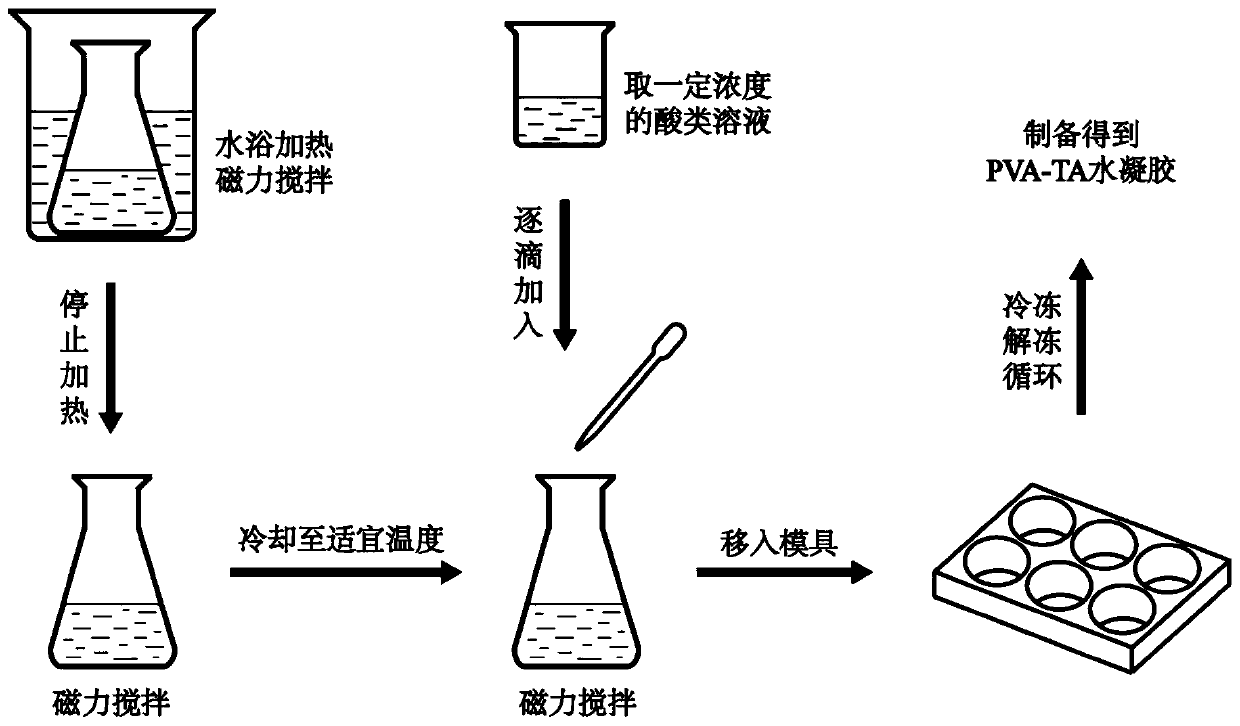

[0028] a) Add 10g of PVA, 1g of TA, 3g of calcium carbonate, and 1g of poloxamer 407 into 85mL of deionized water, heat in a constant temperature water bath at 90°C, and stir until the PVA is completely melted and the remaining substances are evenly mixed to obtain a mixed solution A.

[0029] b) Place the mixed solution A at room temperature and continue to stir until the temperature drops to 25°C for later use. Add 3 mL of acetic acid dropwise to the above mixed solution A according to a certain volume, and continue to stir until the calcium carbonate and acetic acid fully react to generate microbubbles to obtain the mixed solution B.

[0030] c) Pour the mixed solution B into the mold and perform a freeze-thaw cycle. The freezing temperature is -20°C, the freezing time is 15 hours, the thawing temperature is 15°C, and the thawing time is 12 hours. The number of cycles was 3 times to obtain a polyvinyl alcohol hydrogel.

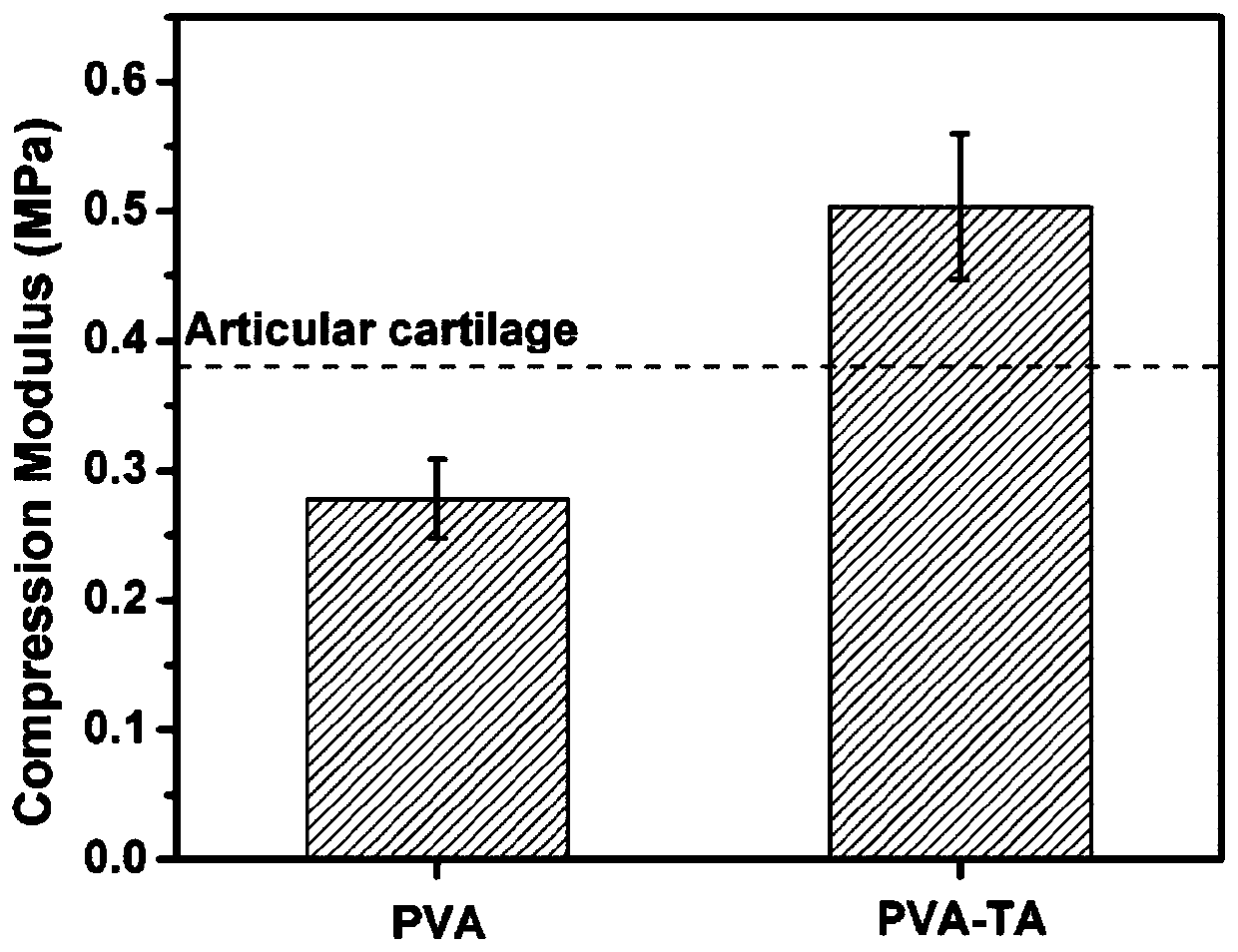

[0031] Based on the PVA-TA hydrogel prepared by the ...

Embodiment 2

[0036] a) Add 20g of PVA, 4g of TA, 2g of calcium carbonate, and 1g of poloxamer 407 into 73mL of deionized water, heat in a constant temperature water bath at 95°C, and stir until the PVA is completely melted and the rest of the ingredients are evenly mixed to obtain a mixture A.

[0037] b) Put the mixed solution A at room temperature and keep stirring, and lower the temperature to 40°C for later use. 3 mL of hydrochloric acid with a mass fraction of 15% was added dropwise to the above mixed solution A according to a certain volume, and the stirring was continued until the calcium carbonate and hydrochloric acid fully reacted to generate microbubbles, and mixed solution B was obtained.

[0038] c) Pour the mixed solution B into the mold, and perform a freeze-thaw cycle. The freezing temperature is -18°C, the freezing time is 20h, and the thawing temperature is 20°C, and the thawing time is 4h. The number of cycles is 2 times to obtain polyvinyl alcohol hydrogel.

[0039] Ba...

Embodiment 3

[0041] a) Add 13g of PVA, 2g of TA, 4g of calcium carbonate, and 1g of poloxamer 407 into 80mL of deionized water, heat in a constant temperature water bath at 99°C, and stir until the PVA is completely melted and the remaining substances are evenly mixed to obtain a mixed solution A.

[0042] b) Place the mixed solution A at room temperature and continue to stir until the temperature drops to 30°C for later use. Add 5 mL of citric acid to the above mixed solution A drop by drop according to a certain volume, and continue to stir until the calcium carbonate and acetic acid fully react to generate microbubbles to obtain the mixed solution B.

[0043] c) Pour the mixed solution B into the mold and perform a freeze-thaw cycle. The freezing temperature is -25°C, the freezing time is 18 hours, and the thawing temperature is 23°C, and the thawing time is 6 hours. The number of cycles was 4 times to obtain a polyvinyl alcohol hydrogel.

[0044] Based on the PVA-TA hydrogel prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com