Preparation method of reactive porous Sn-Bi electrode, as well as porous Sn-Bi electrode and application thereof

A reactive, porous and conductive technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low degradation efficiency of organic matter, overcome easy cracking and deformation, improve electrocatalytic performance, and solve the problem of electrical conductivity poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

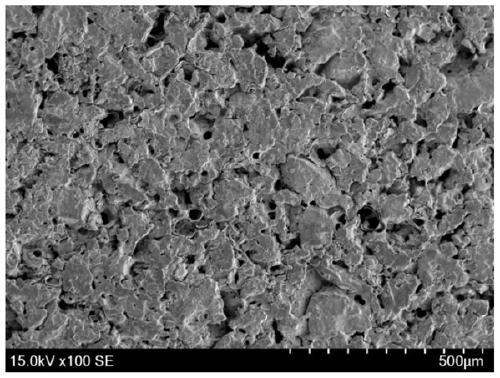

[0031] Example 1 A reactive porous tin-bismuth electrode X1 and its preparation method

[0032] Its preparation method comprises the following steps:

[0033] Step 1: Etching pretreatment of porous titanium conductive substrate

[0034] Boil porous titanium with a length of 50mm, a width of 20mm, a thickness of 2mm, and a pore size of 30μm in 10% sodium hydroxide solution and 10% oxalic acid solution for 30 minutes, etch until a gray pitted titanium matrix is formed, take it out and wash it with nitrogen blow dry.

[0035] Step 2: Configure tin-bismuth sol

[0036] Measure 200mL of ethylene glycol, add a certain amount of citric acid, stir and dissolve at 60°C, then add SnCl to the solution 4 4H 2 O and Bi(NO 3 ) 3 ·5H 2O, after raising the temperature to 90°C and maintaining it for 30 minutes, a mixed solution of tin and bismuth was formed. Add 0.5% (g / mL) PVA to the tin-bismuth mixture and keep stirring to obtain a colorless transparent or slightly yellow sol after...

Embodiment 2

[0040] Example 2 A reactive porous tin-bismuth electrode X2 and its preparation method

[0041] Its preparation method comprises the following steps:

[0042] The first step: porous carbon conductive substrate etching pretreatment

[0043] Porous carbon with a diameter of 15 mm, a thickness of 2 mm, a length of 8 mm, and an average pore diameter of 10 μm was etched in 10% nitric acid solution for 30 min, and then cleaned and dried with nitrogen gas after taking it out.

[0044] Step 2: Configure tin-bismuth sol

[0045] Measure 200mL of ethylene glycol, add a certain amount of citric acid, stir and dissolve at 60°C, then add SnCl to the solution 4 4H 2 O and Bi(NO 3 ) 3 ·5H 2 After O was heated to 90°C and kept for 30 min, a mixture of tin and bismuth was formed. Add 0.1% (g / mL) PVB to the tin-bismuth mixture, and obtain a colorless transparent or slightly yellow sol after cooling, which is the polymer-tin-bismuth composite precursor. The compound ratio is citric acid:...

Embodiment 3

[0049] Example 3 A reactive porous tin-bismuth electrode X3 and its preparation method

[0050] Its preparation method comprises the following steps:

[0051] Step 1: Etching pretreatment of porous titanium conductive substrate

[0052] Boil a tubular porous titanium substrate with a length of 30 mm, a thickness of 1 mm, an outer diameter of 15 mm, and a pore diameter of 50 μm in 10% NaOH solution and 10% oxalic acid solution for 30 minutes, etch until a gray pockmarked titanium substrate is formed, take it out and wash it for use Blow dry with nitrogen.

[0053] Step 2: Configure tin-bismuth sol

[0054] Measure 200mL of ethylene glycol, add a certain amount of citric acid, stir and dissolve at 60°C, then add SnCl to the solution 4 4H 2 O and Bi(NO 3 ) 3 ·5H 2 After O was heated to 90°C and kept for 30 min, a mixture of tin and bismuth was formed. Add 3% (g / mL) PVA to the tin-bismuth mixture and keep stirring, and after cooling, a colorless, transparent or slightly ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com