Multifunctional downhole tool maintenance assembling rack and using method

A technology for downhole tools and assembling racks, applied in the fields of oil drilling and natural gas well completion, can solve the problems of high labor intensity, low work efficiency, uncontrollable thread tightening torque, etc., so as to reduce labor intensity, improve work efficiency, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

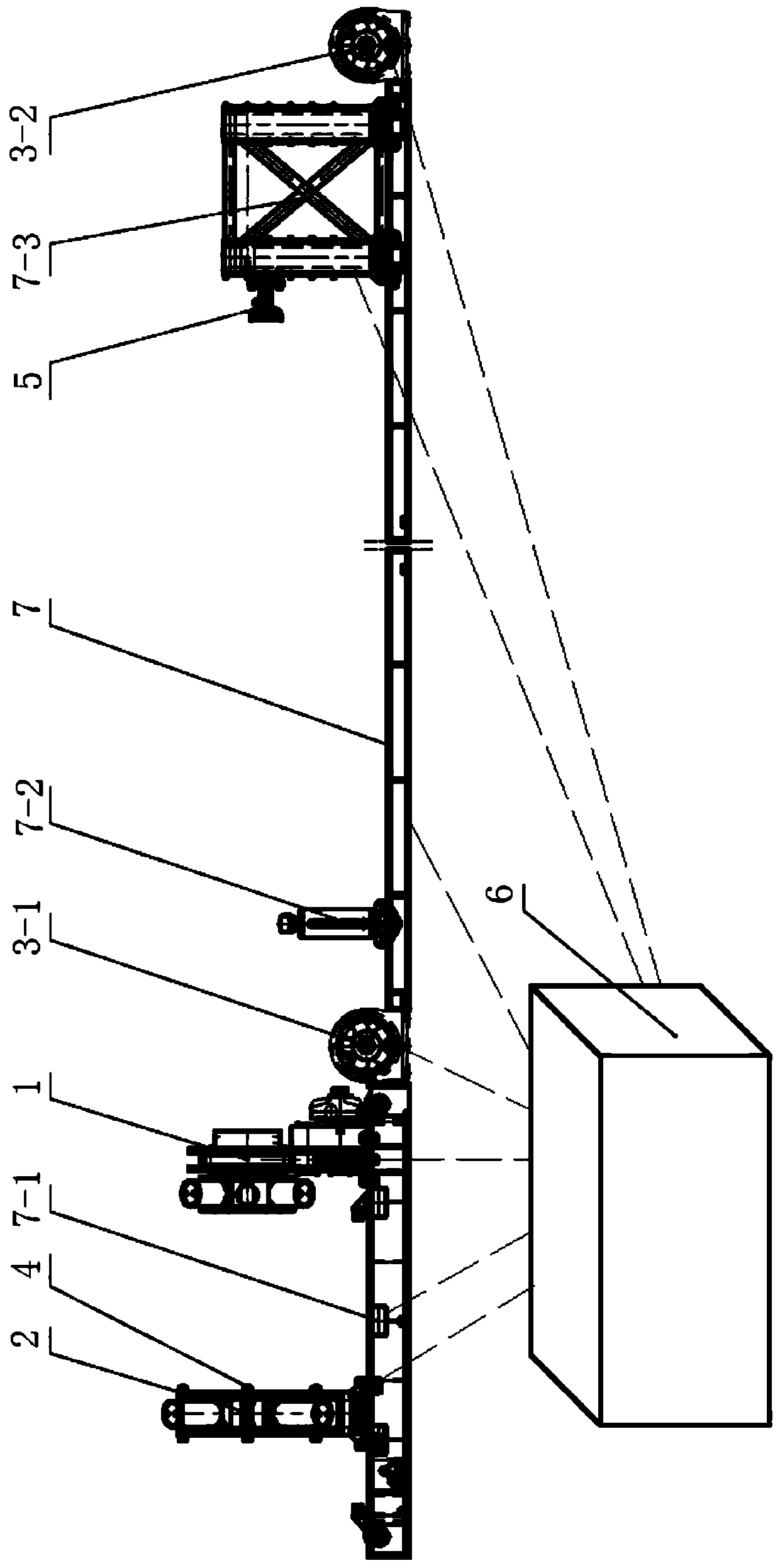

[0027] refer to figure 1 , the multifunctional downhole tool maintenance assembly frame of the present invention includes a main body 7, the front part of the main body 7 is provided with a guide rail 7-1, and the guide rail 7-1 is provided with a The main tong assembly 1 and the back tong assembly 2 that can move left and right through its bottom drag chain, the rear part of the main body 7 is provided with a trailer 7-3, and the trailer 7-3 is connected with a wire rope and located in front of it. , the first hydraulic winch 3-1 and the second hydraulic winch 3-2 on the rear two sides can move forward and backward under the dragging of the first hydraulic winch 3-1 and the second hydraulic winch 3-2, and the A liftable support frame 7-2 for supporting downhole t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com