A processing method for non-revolving reflective surface structure of rotating semi-ellipsoid

A processing method and reflective surface technology, applied in the direction of mirrors, etc., can solve the problems of limited popularization and application, large structural size, difficulty in meeting precision requirements, etc., and achieve the effects of promoting popularization and application, good controllability of results, and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described below in conjunction with the accompanying drawings. It should be understood that the process described here is only used to illustrate and explain the present invention, and is not intended to limit the present invention.

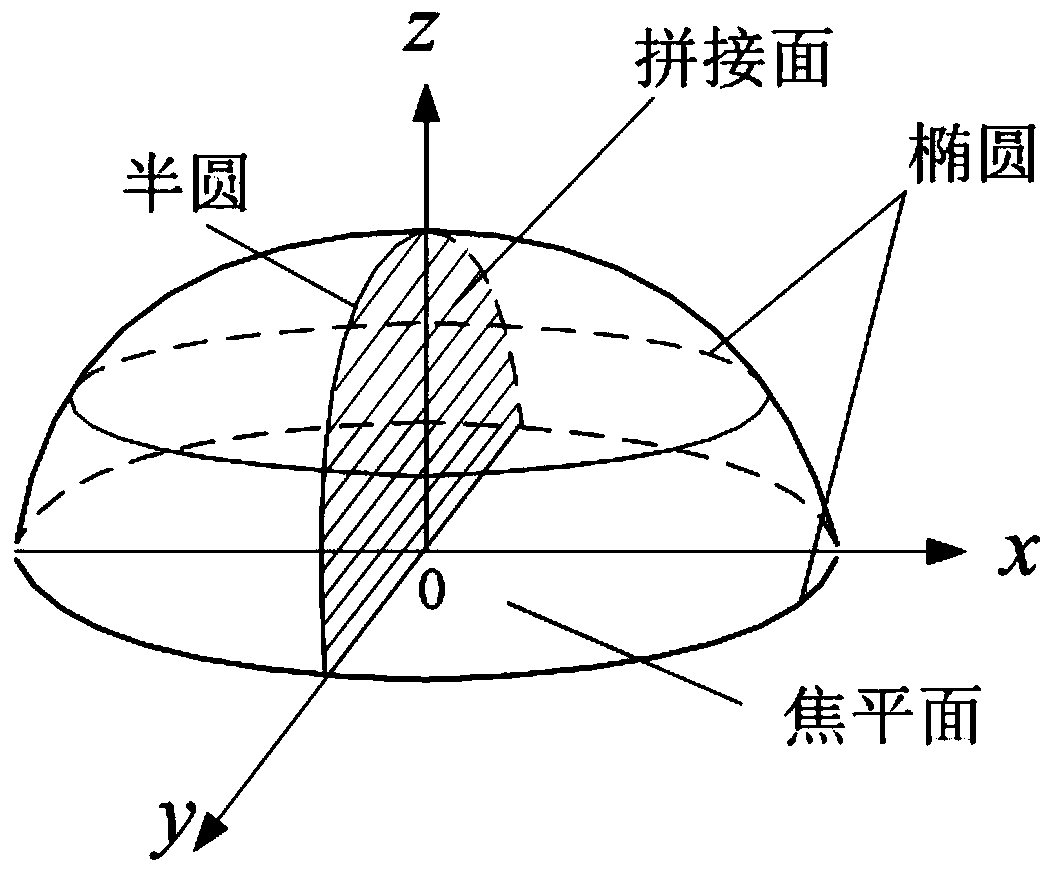

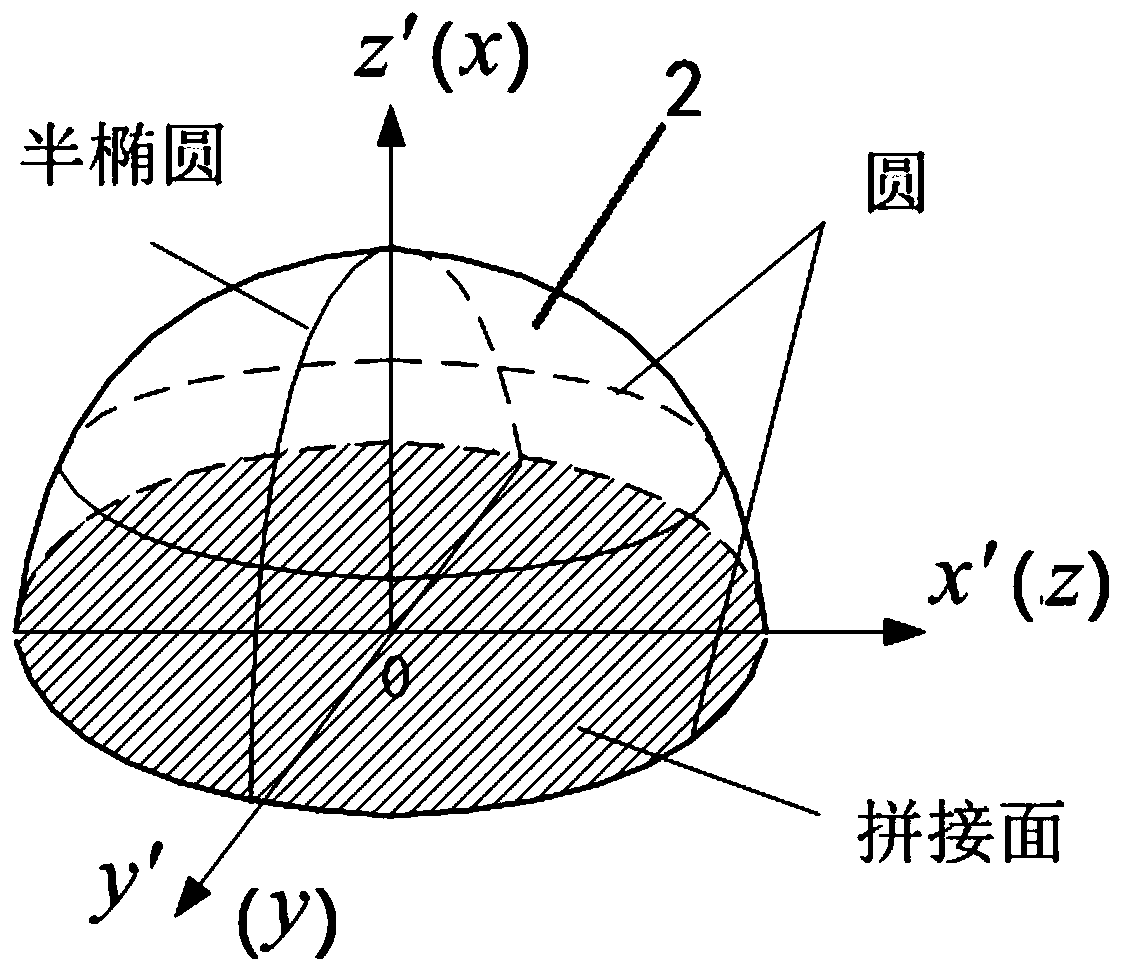

[0050] For the non-revolving reflector structure of the rotating semi-ellipsoid, its horizontal cross-section is an ellipse, and its normal section is a semicircle, which cannot be processed with high precision by a lathe.

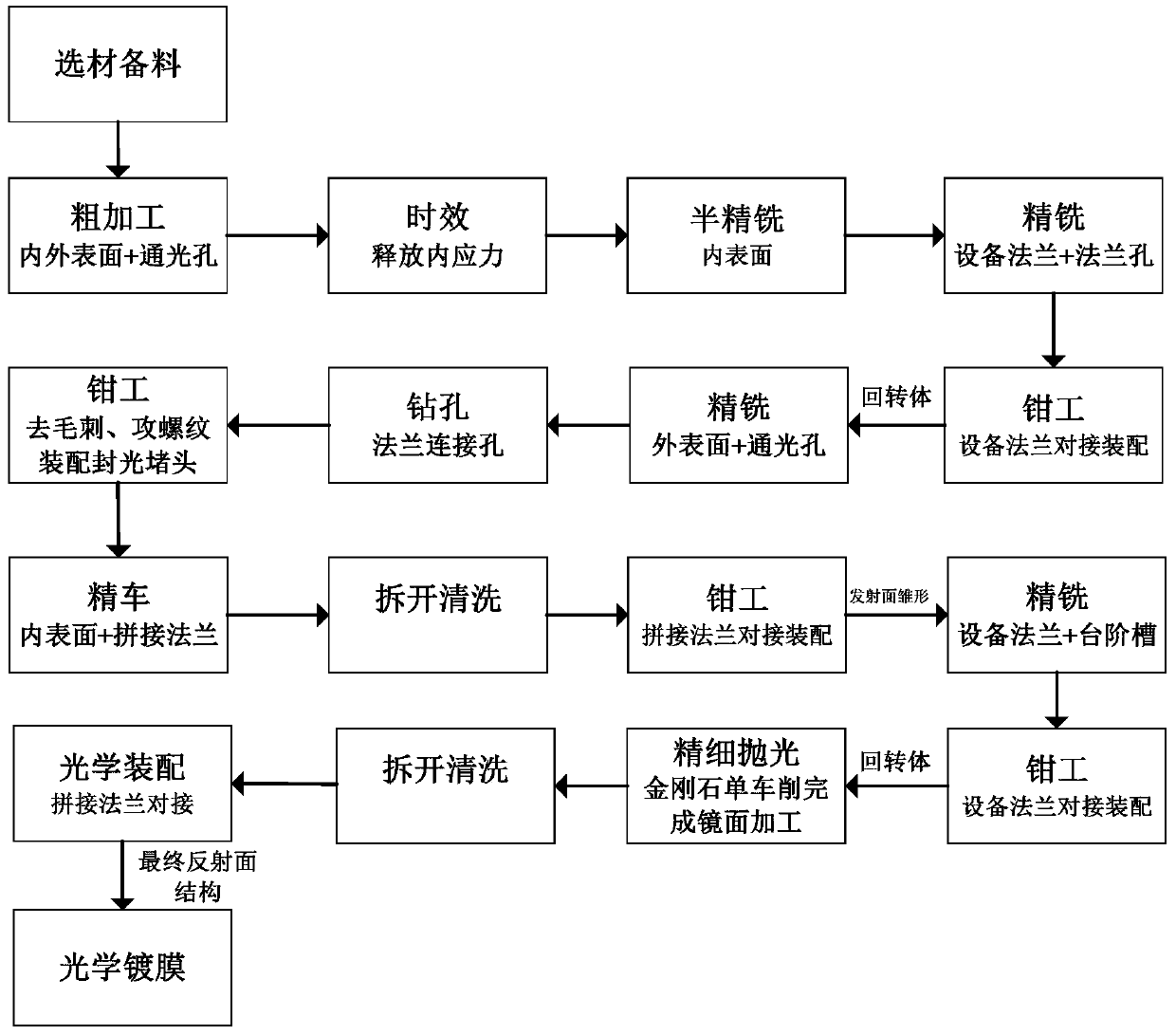

[0051] Therefore, the present invention provides a processing method for a non-revolving reflective surface structure of a rotating semi-ellipsoid. Since the structure of a non-revolving reflective surface of a rotating semi-ellipsoid is spliced by two 1 / 4 ellipsoidal shells, the specific implementation steps of its processing Yes, the specific process is as follows figure 1 Shown:

[0052] Step 1) Establish a coordinate system XYZ according to the structure of the non-revolving reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com