A self-feeding continuous cutting device for steel pipes

A cutting device and self-feeding technology, which is applied in the direction of pipe shearing device, shearing device, and accessory device of shearing machine, etc., can solve the problems of low degree of automation and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

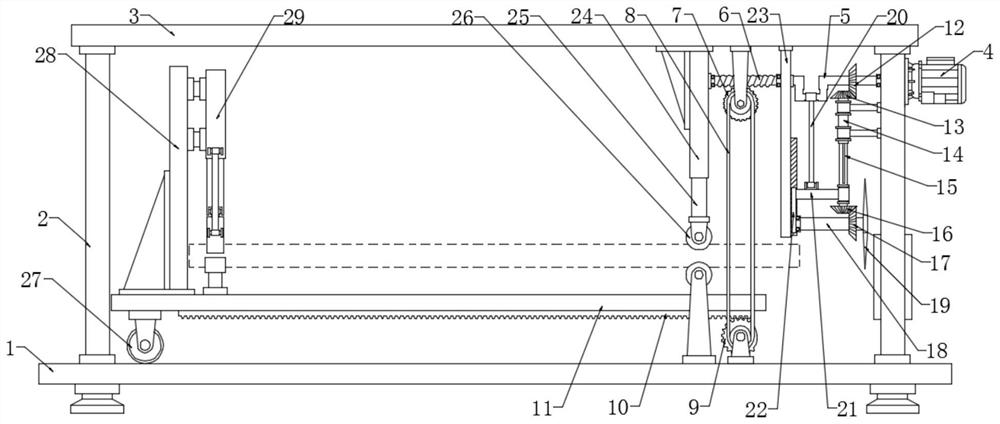

[0023] see Figure 1~3 , in an embodiment of the present invention, a self-feeding continuous cutting device for steel pipes includes a base plate 1, a crankshaft 5, a residual gear 9, a workbench 11, a cutter 19, a clamping wheel 26 and a fixing device 29; above the base plate 1 Side plates 2 are respectively fixed on both sides, and a top plate 3 is fixed above the side plates 2, wherein a driving motor 4 is fixedly installed on one side of the side plate 2 through a flange. Through the side plate 2 and connected with the bearing in rotation, the driving motor 4 wire is connected to the power supply and the switch, and the switch is activated to make the driving motor 4 energized to drive the crankshaft 5 to rotate; the crankshaft 5 is fixedly connected to the worm 6, and the bearing at the end of the worm 6 is connected to the hydraulic pressure. The side wall of the cylinder 24, the upper end of the hydraulic cylinder 24 is fixed on the top plate 3 through reinforcing ribs...

Embodiment 2

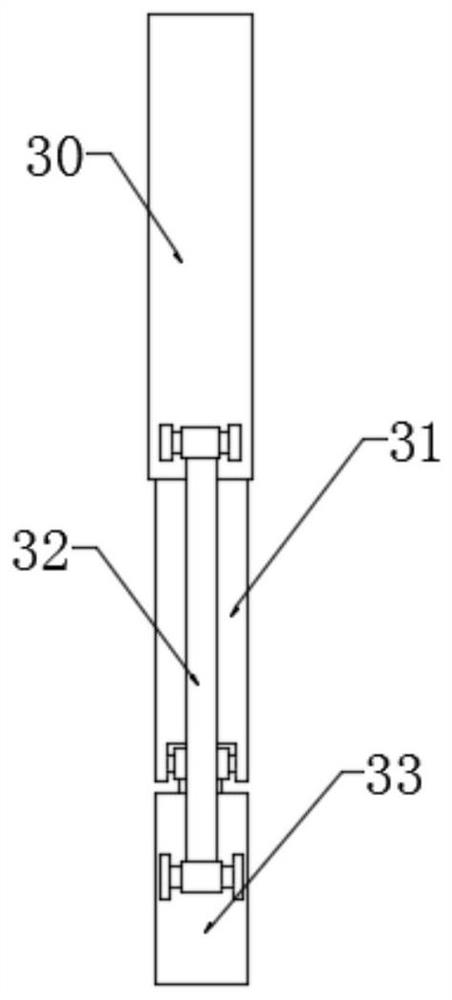

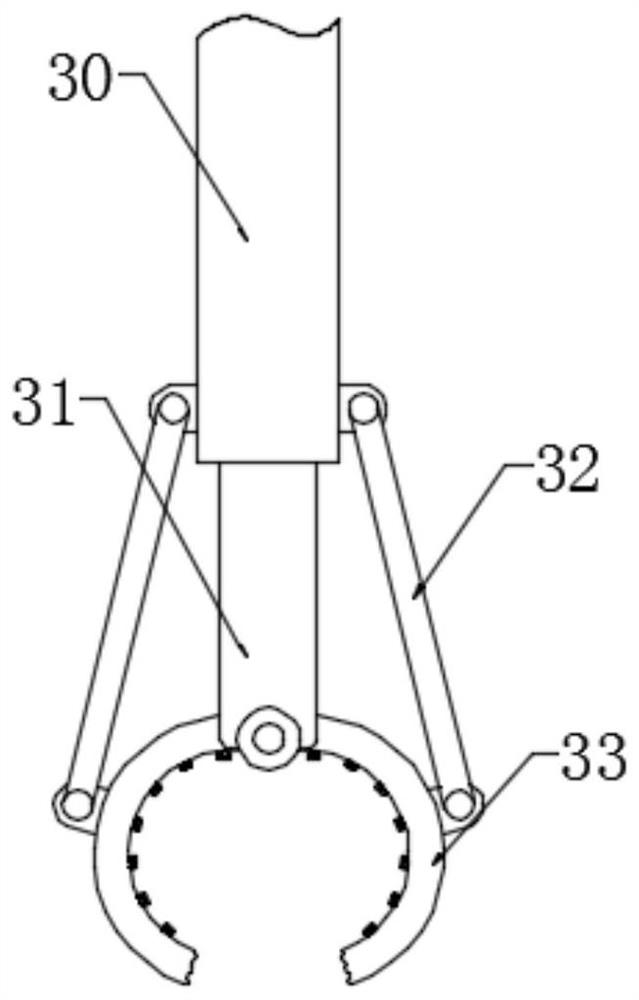

[0027] In order to further explain the above-mentioned self-feeding continuous cutting device for steel pipes, this application provides another embodiment. The self-feeding continuous cutting device for steel pipes in this embodiment has the following technical features: the workbench 11 is fixedly connected to There is a tail plate 28, and the side wall of the tail plate 28 is provided with a fixing device 29. Specifically, the fixing device 29 includes a cylinder 30, a piston rod 31, a drive rod 32 and a claw 33, wherein the cylinder 30 is fixed on the tail plate 28, The bottom of the cylinder 30 is slidingly connected to the piston rod 31, and the two sides of the lower end of the piston rod 31 are respectively rotated to connect with the claws 33. The middle part of the claw 33 is connected to the two sides below the cylinder 30 through the drive rod 32, and the cylinder 30 is used to drive the piston rod 31 to move up and down to drive The driving rod 32 drives the claw 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com