Nano-cobalt/cobalt sulfide loaded heteroatom doped porous carbon composite catalyst and preparation method and application thereof

A technology of cobalt sulfide and nano-cobalt, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as increasing the complexity of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

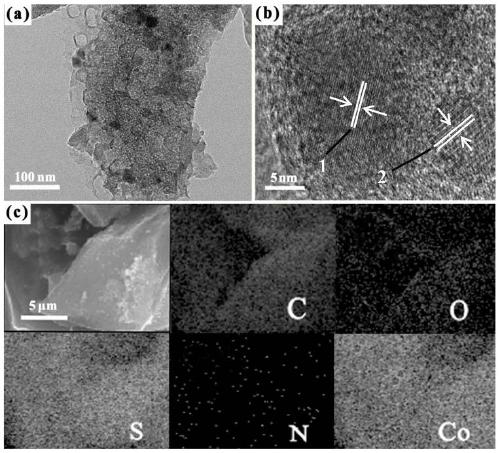

[0031] Example 1: Synthesis of nano-cobalt / cobalt sulfide supported on heteroatom-doped porous carbon composite electrocatalytic monolithic water splitting catalyst

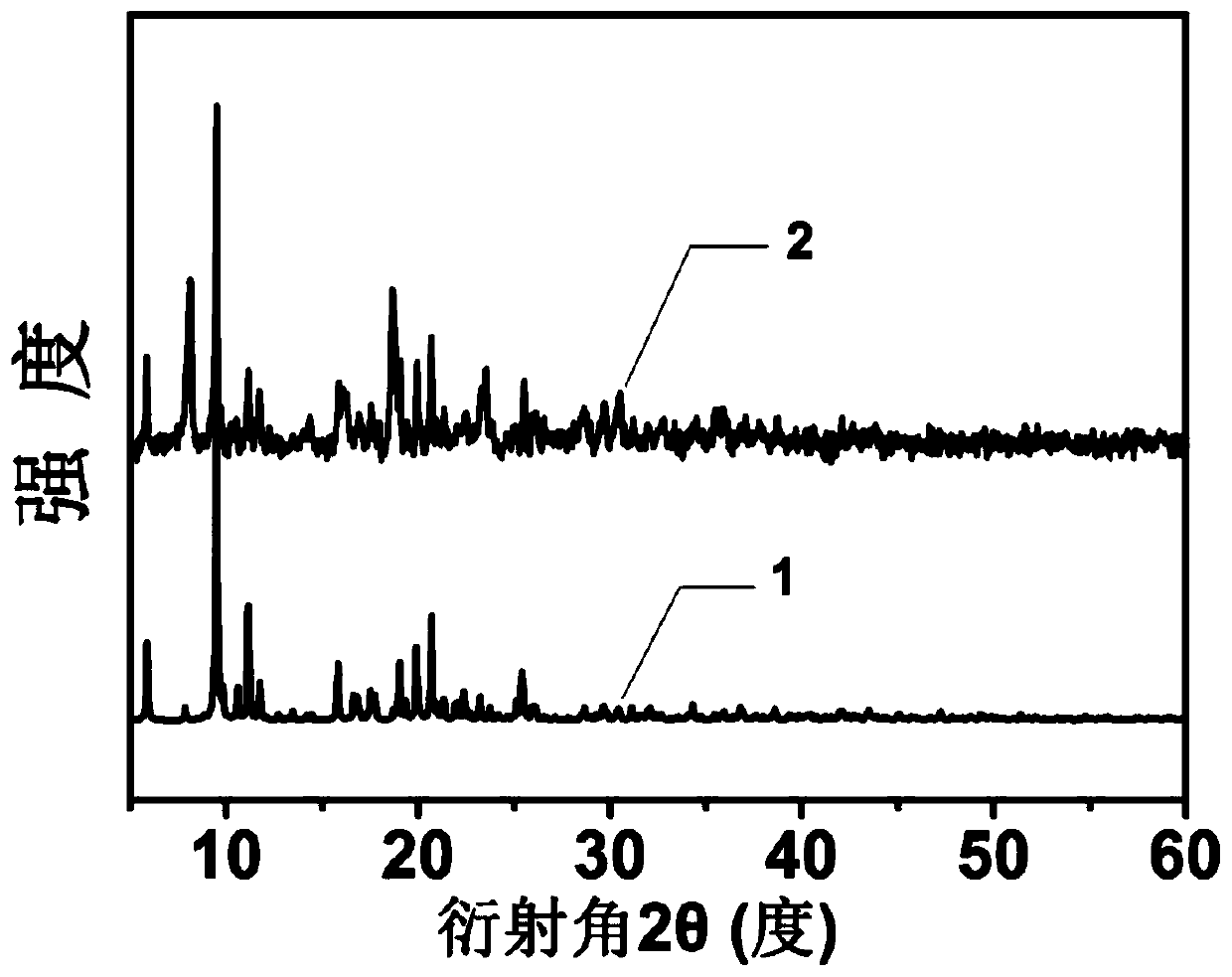

[0032] (1) Dissolve 0.435g of cobalt nitrate hexahydrate, 0.172g of 2,5-thiophenedicarboxylic acid and 0.198g of 1,3-bis(4-pyridyl)propane in 30mL of N,N-dimethylformamide, Stir at room temperature for 2h. Then stirred and refluxed at 120° C. for 12 h to obtain a purple turbid solution. After filtering, washing with water and vacuum drying, the precursor (Co-NSOMOF) was ground to obtain a purple solid powder. PXRD of the precursor such as figure 1 As shown, the as-prepared precursors almost completely match the PXRD peaks simulated with single crystal data, indicating that the as-prepared precursors have high crystallinity and purity.

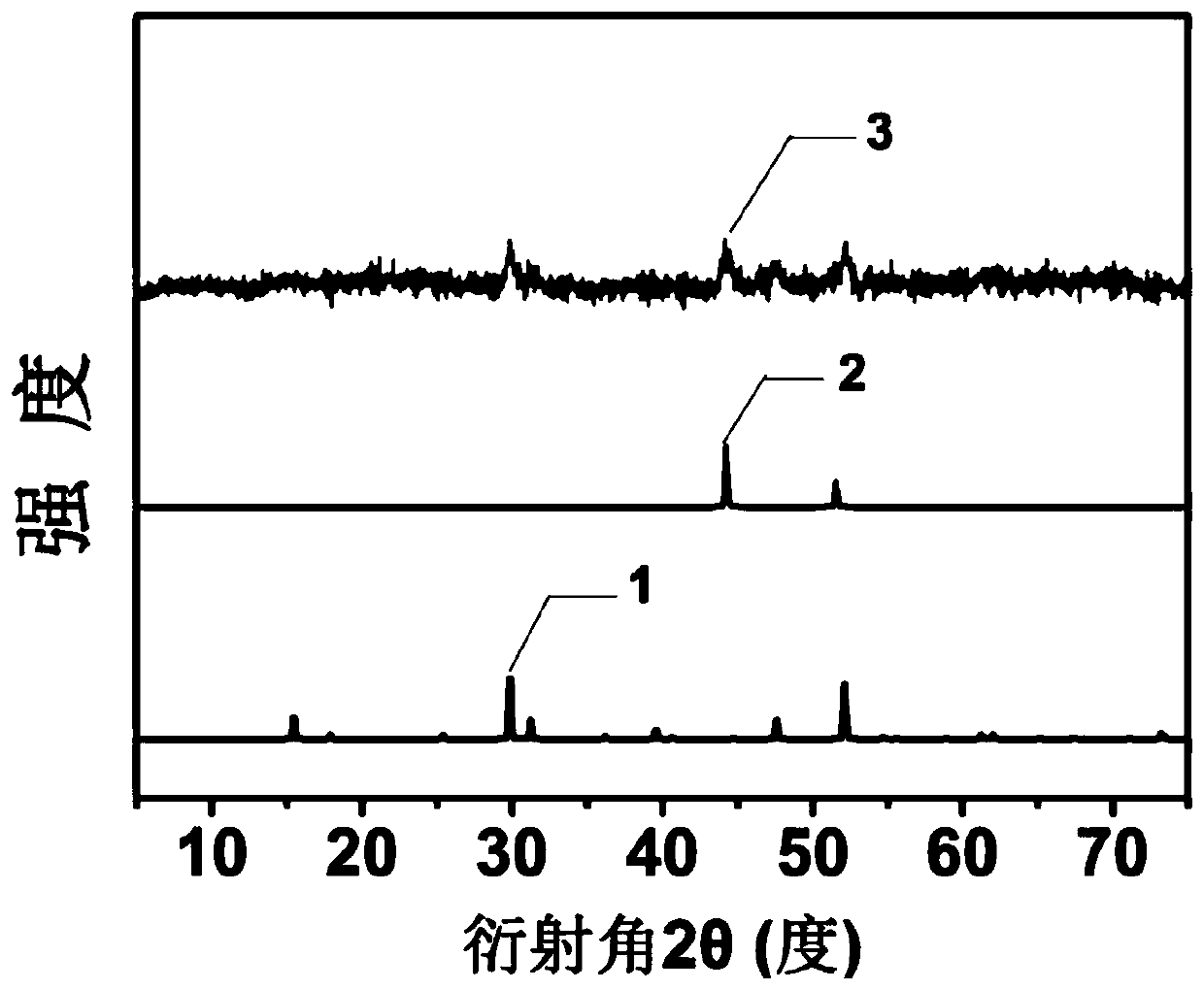

[0033](2) 400 mg of the purple solid powder obtained in step (1) is placed in a quartz boat, and the quartz boat is placed in a tube furnace, and the air in the furnace is exha...

Embodiment 2

[0036] Example 2: Performance test of nano cobalt / cobalt sulfide supported on heteroatom-doped porous carbon composite material of the present invention as an electrocatalyst

[0037] Preparation of electrocatalyst working electrode:

[0038] Co / Co prepared by the present invention by 2mg 9 S 8 The @NSOC catalyst was dispersed in 220 μL of Nafion solution containing 100 μL of water, 100 μL of DMF and 20 μL of 5% by mass, and then sonicated for 30 minutes to obtain a slurry with uniform catalyst dispersion. Then, 5 μL of the slurry was drop-coated on the surface of the glassy carbon electrode using a micropipette, and then dried at room temperature for use. The electrocatalyst performance test adopts a three-electrode system, and the electrolyte is 1mol L -1 aqueous potassium hydroxide solution. The test instrument is Shanghai Chenhua CHI660E Electrochemical Workstation.

[0039] Figure 5 It is the electrocatalytic oxygen evolution property test diagram of the catalyst o...

Embodiment 3

[0044] Example 3: Application of nano-cobalt / cobalt sulfide supported by heteroatom-doped porous carbon composite catalysts prepared in the present invention in monolithic water-splitting electrolytic cells

[0045] Figure 10 The catalyst prepared by the present invention is respectively used as the cathode and the anode of the integral water splitting electrolytic cell, and the electrolyte is 1mol L -1 Aqueous potassium hydroxide solution, obvious hydrogen and oxygen generation can be observed.

[0046] Figure 11 Linear scanning polarization curves of the monolithic water-splitting electrolysis cell assembled using the prepared catalyst as cathode and anode materials, when the current density is 10mA cm -2 , with a lower battery voltage of 1.56V.

[0047] Such as Figure 12 As shown, the overall water splitting electrolytic cell assembled with the prepared catalyst of the present invention has no obvious change in the relevant current after 10 h of chronoamperometry tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com