Device for forming steamed stuffed bun

A molding device and technology for buns, applied in the field of bun machines, can solve the problems of uneven skin thickness of buns, poor overall aesthetics, poor molding effect, etc., and achieve the effects of not easily revealing stuffing, high work efficiency, and firm sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

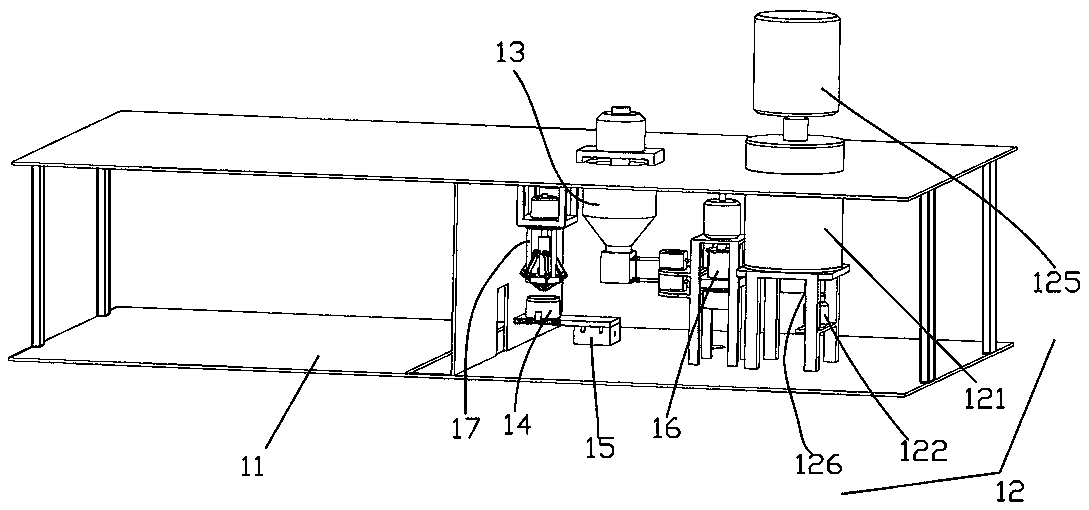

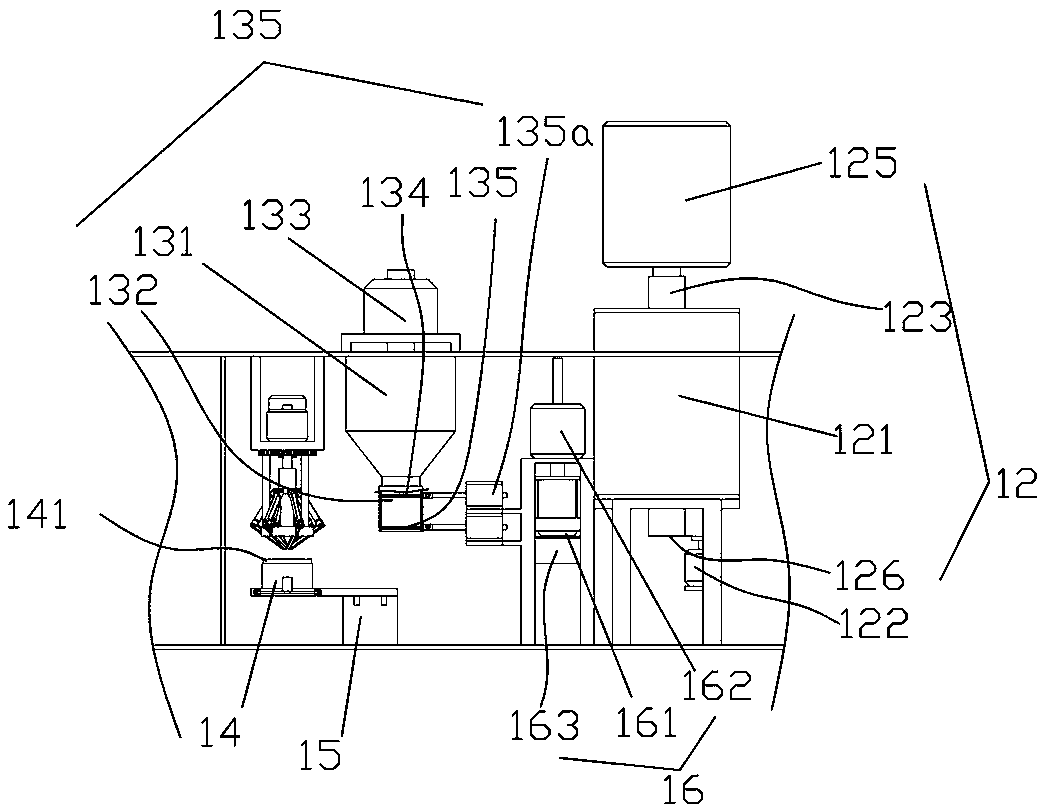

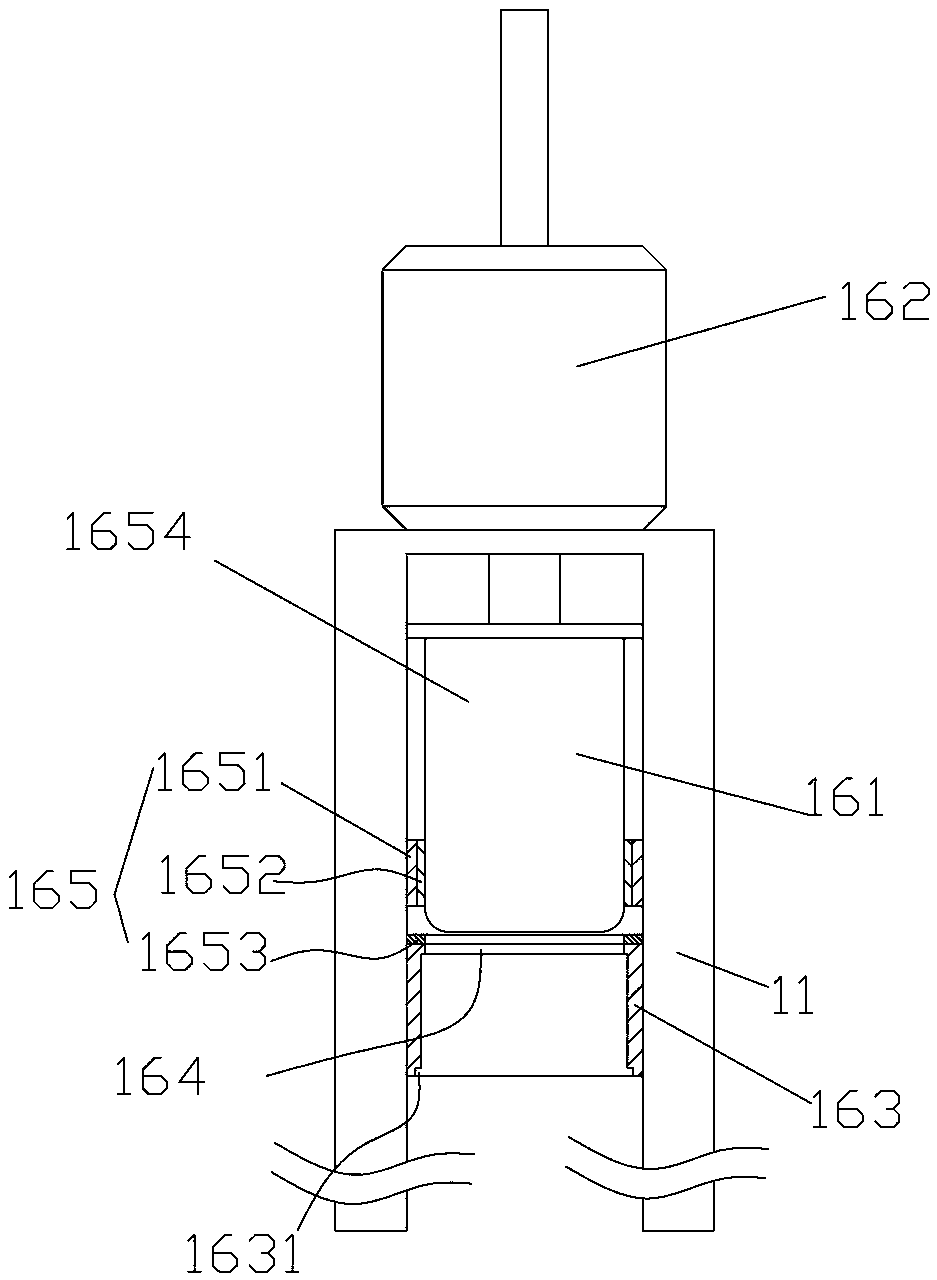

[0032] Embodiment 1: as Figure 1-7As shown, a bun forming device includes a frame 11, a dough outlet device 12 and a stuffing outlet device 13 arranged on the frame 11, and a movable dough blank that can receive the dough in the dough outlet device 12 Lower mold 14, the moving slide table 15 that is used to install described dough lower mold 14, the extruding mechanism 16 that is used to extrude the dough agent in the dough lower mold 14 into steamed stuffed bun skin and the filling device The stuffing in 13 is packed into the steamed stuffed bun sealing mechanism 17 that is used for steamed stuffed bun skin sealing after packing into; In the present embodiment, mobile slide table 15 can realize moving by screw screw mechanism, also can realize moving by the promotion of cylinder. Specifically, the extrusion molding mechanism 16 includes a dough mold core 161 that can be inserted into the dough lower mold 14 for extrusion molding, and a dough molding linear motor 162 that dri...

Embodiment 2

[0041] Embodiment 2: Different from Embodiment 1, the stuffing storage box 131 includes a stuffing storage box 1311, and a plurality of ring-shaped motor brackets 1312 arranged in the entrance of the stuffing storage box 1311. The entrance of the box body 1311 is large at the top and small at the bottom. The motor bracket 1312 divides the entrance of the stuffing storage box 1311 into multiple feeding channels. extend. This setting, when the stuffing pushing plate 1331 is lifted into the entrance of the stuffing storage box 1311, can directly feed to the entrance of the stuffing storage box 1311, which is conducive to improving work efficiency.

[0042] In order to prevent the filling from remaining on the upper surface of the stuffing pushing plate 1331 during feeding, preferably, the bottom of the body of the stuffing pushing linear motor 1332 is provided with an accommodating ring 1313 for accommodating the stuffing pushing plate 1331 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com