Pasting, steaming and cutting all-in-one machine for producing sheet jelly

An all-in-one machine and sizing technology, which is applied in food forming, food science, application, etc., can solve the problems of restricting the promotion of scalding skin, difficulty in large-scale and large-scale production, and low production efficiency, so as to achieve compact structure and high production efficiency. The effect of high efficiency and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

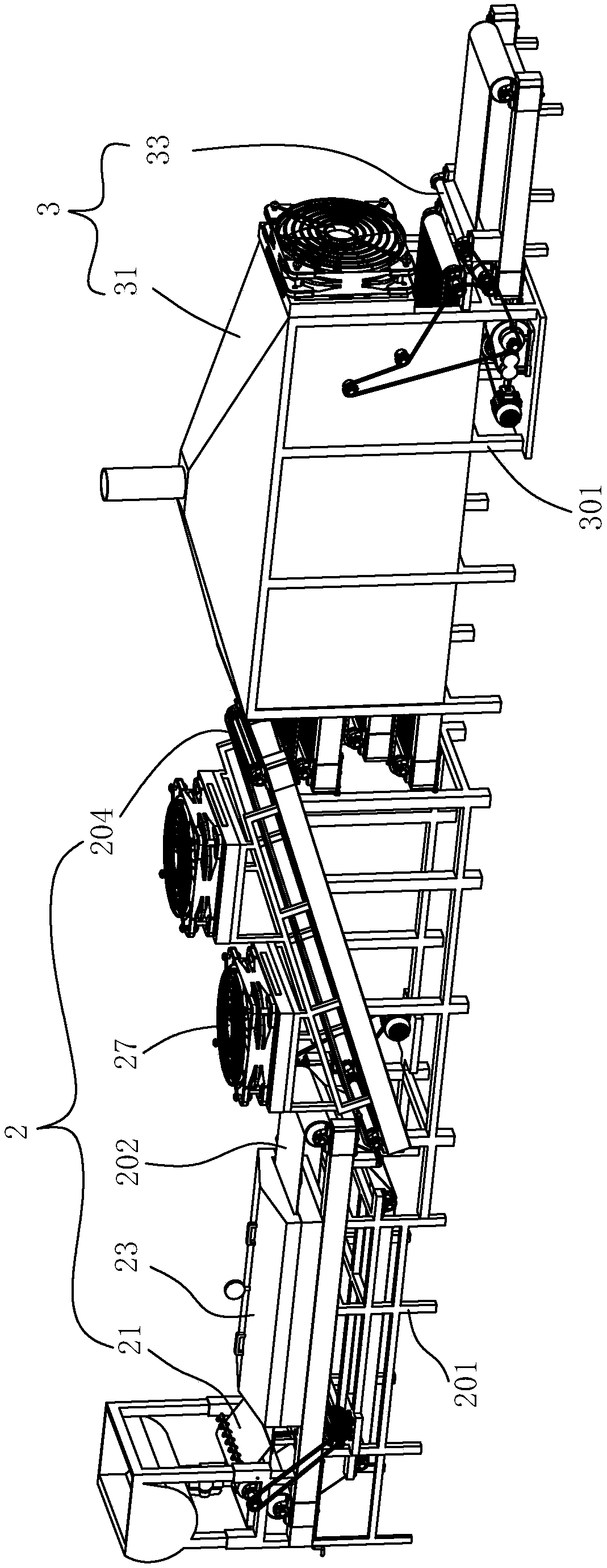

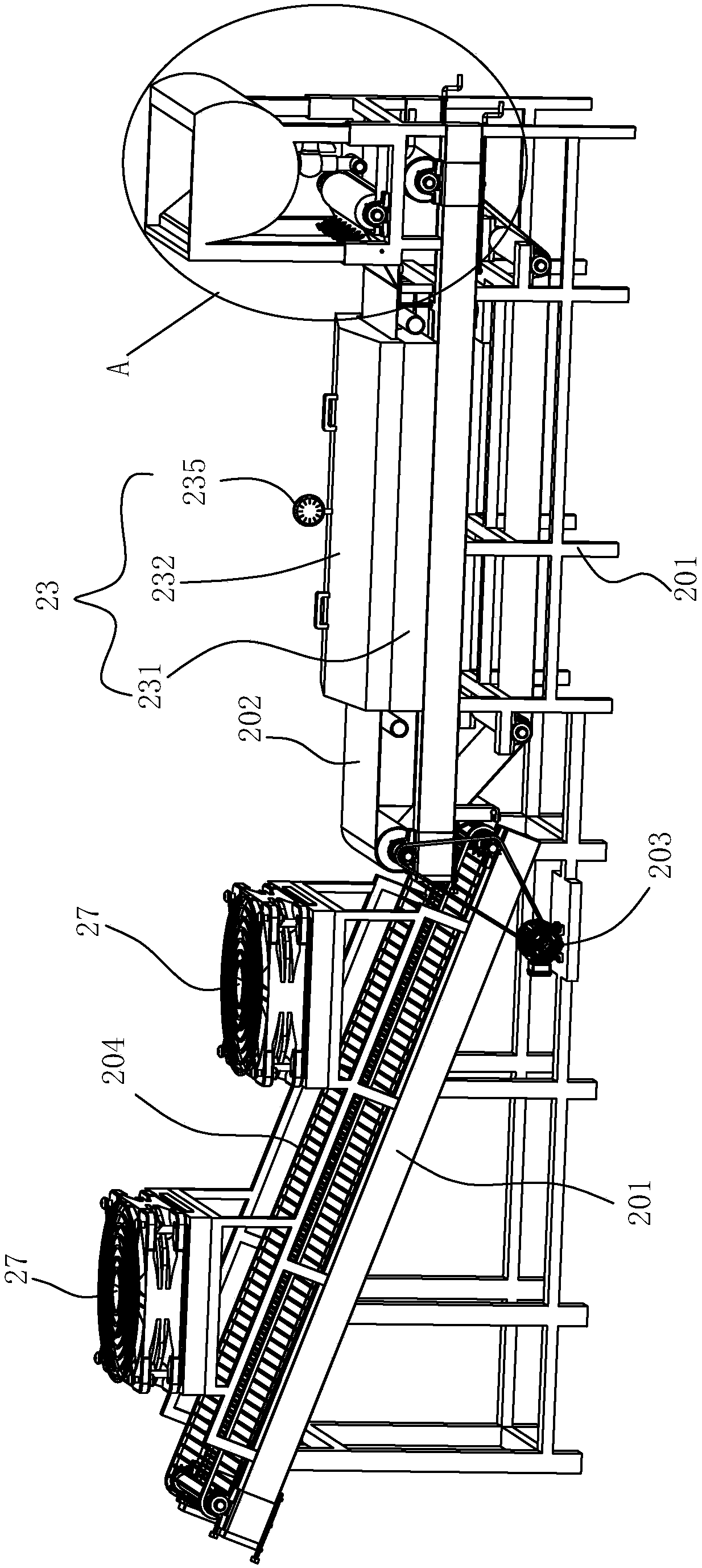

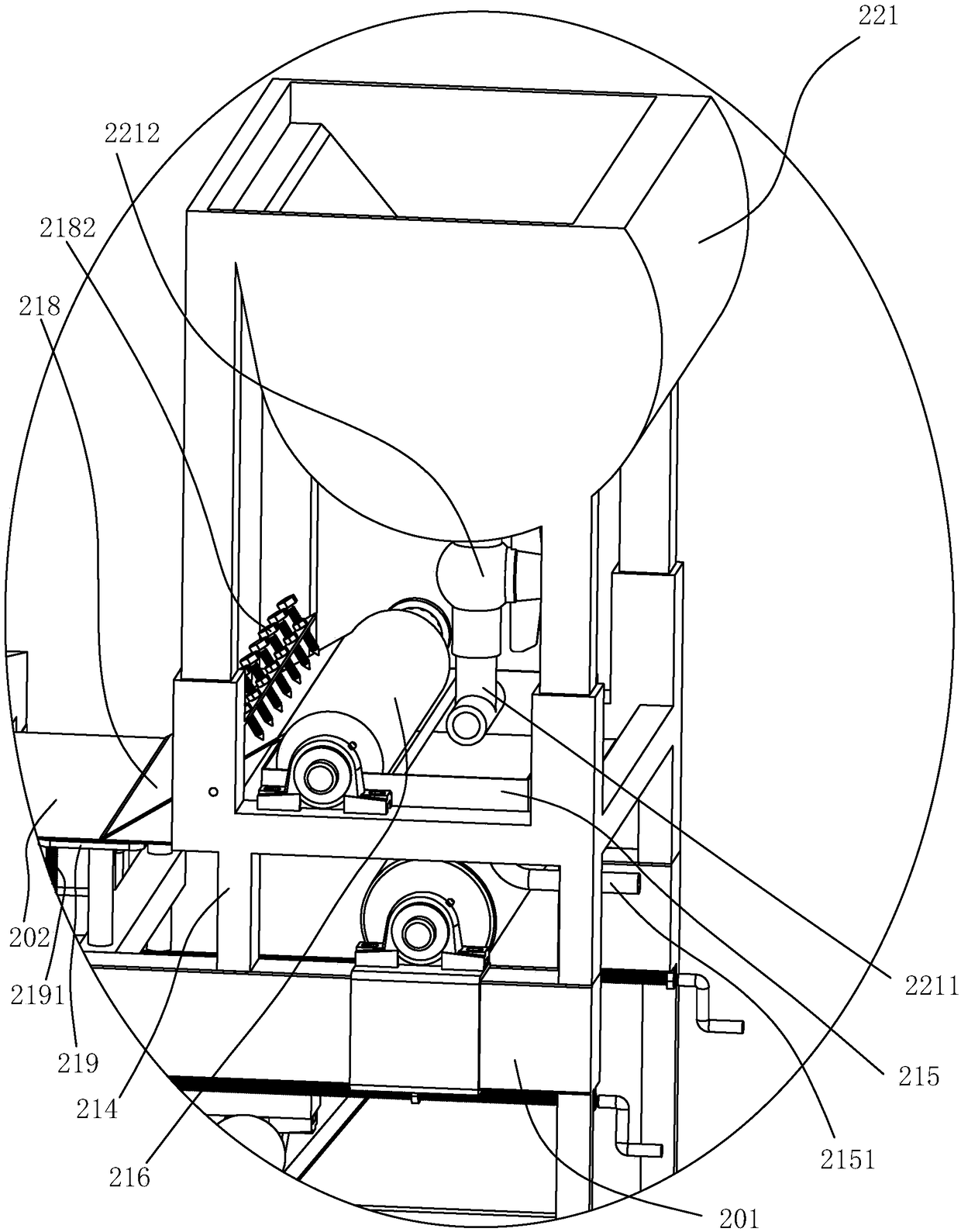

[0031] Such as figure 1 As shown, in this embodiment, an integrated machine for sizing, steaming, and cutting for producing scalds is provided with a sizing, steaming and stripping station, a pre-drying and cutting station in sequence along the production direction of the scalding, including: Steaming and stripping equipment 2 and pre-drying and cutting equipment 3; the steamed and stripped equipment 2 for sizing and steaming is set at the steaming and stripping station A01 for coating the rice pulp prepared by the pulping equipment On the horizontal conveyor belt device A202 and steam the rice milk on the horizontal conveyor belt device A202, then peel off the hot skin from the horizontal conveyor belt device A202; Bit A02 is used for pre-drying the peeled skin peeled off from the horizontal conveyor belt device A202, and then cutting off the peeled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com