Method of using corn distilled grains and waste bean dregs to ferment and produce animal feed

A technology of corn distillers grains and animal feed, which is applied in the direction of animal feed, animal feed, application, etc., can solve the problems such as probiotics that have not yet appeared, and achieve the effects of enhancing animal immunity, increasing amino acid content, and improving intestinal environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

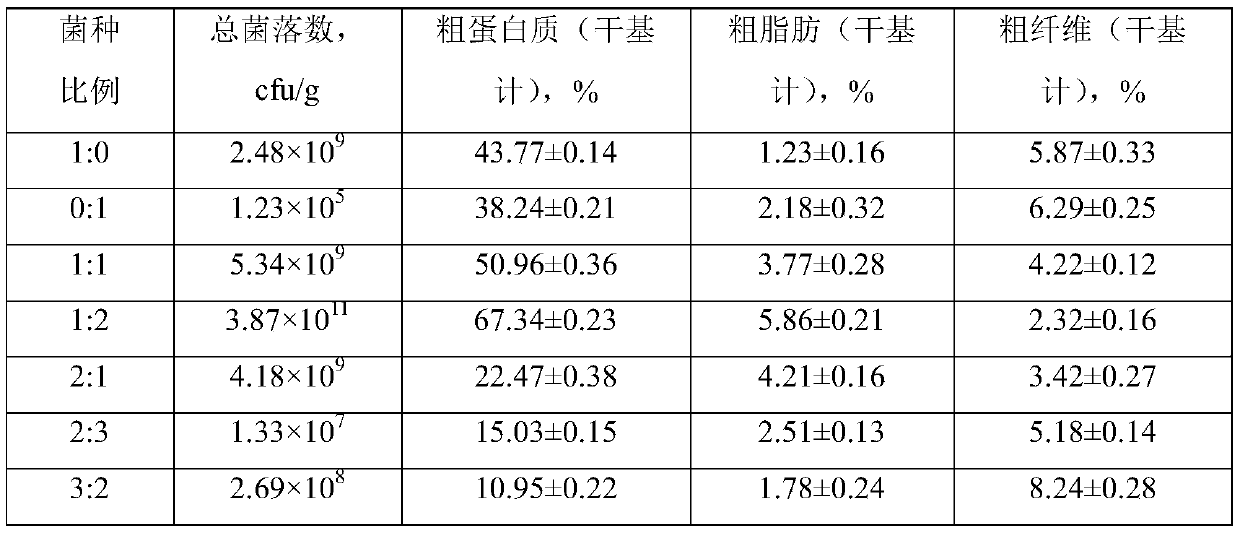

[0047] In this example, the inoculation ratios of Bacillus subtilis and Clostridium butyricum were investigated, and the seed liquids of Bacillus subtilis and Clostridium butyricum in different proportions were inserted into corn distiller's grains according to the inoculation amount of 5% (V / W). Put it in a solid fermentation medium with a ratio of 2:3 to bean dregs, put it in a fermenter, and ferment at a temperature of 35°C. First, ferment aerobically for 24 hours, and then pass in an air volume of 0.5 (V / V m), and then ferment anaerobically for 48 hours. , the amount of nitrogen gas introduced is 0.5 (V / V·m). The ratio of Bacillus subtilis: Clostridium butyricum was 1:0, 0:1, 1:1, 1:2, 2:1, 2:3, 3:2, and the total colony number and crude protein ( dry basis), crude fat (dry basis), crude fiber (dry basis), the results are shown in Table 1. As known from Table 1, Bacillus subtilis plays a key role in the total number of colonies, and the number of colonies with Bacillus su...

Embodiment 2

[0051] The present invention investigates the ratio of corn distiller's grains and bean dregs in the solid fermentation medium. The liquid seed solution with a ratio of 1:2 of Bacillus subtilis and Clostridium butyricum is added according to the inoculation amount of 5% (V / W). Proportionate solid fermentation medium, placed in a fermenter at a fermentation temperature of 35°C, aerobic fermentation for 24 hours, air flow of 0.5 (V / V m), and anaerobic fermentation for 48 hours, nitrogen flow of 0.5 (V / V·m). The ratios of corn distiller's grains and bean dregs are 0:1, 1:0, 1:1, 1:2, 1:3, 2:1, 2:3 respectively, and the total number of colonies and crude protein (dry basis) of the fermentation products are determined ), crude fat (dry basis), crude fiber (dry basis), the results are shown in Table 2. As can be seen from Table 2, in the experiment of corn distiller's grains or bean dregs alone, the physical and chemical indicators of the fermentation products are very low. When th...

Embodiment 3

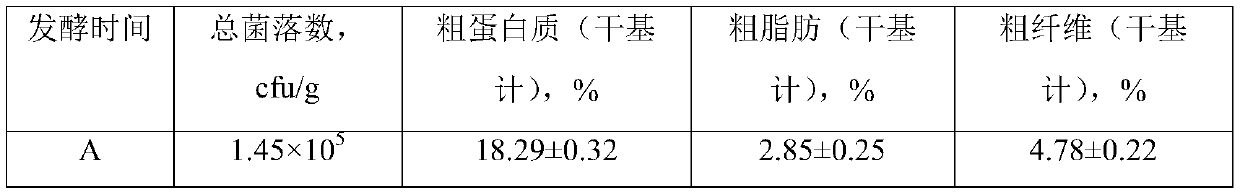

[0055] The present invention investigates the solid-state fermentation time, the ratio of Bacillus subtilis and Clostridium butyricum is 1:2 liquid seed solution, according to 5% (V / W) inoculum amount, the ratio of adding corn distiller's grains and okara is 2: In the solid medium of 3, the fermentation temperature is 35°C, the air volume is 0.5 (V / V m) during aerobic fermentation, and the nitrogen volume is 0.5 (V / V m) during anaerobic fermentation, and the fermentation time is respectively A: Early aerobic 0h, late anaerobic 72h; B: Early aerobic 12h, late anaerobic 60h; C: Early aerobic 24h, late anaerobic 48h; D: Early aerobic 36h, late anaerobic 36h; E: Aerobic 48h in the early stage, anaerobic 24h in the late stage. The total number of colonies, crude protein (dry basis), crude fat (dry basis) and crude fiber (dry basis) of the fermentation product were measured, and the results are shown in Table 3. As can be seen from Table 3, the number of colonies in a completely ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com