High-precision short coherent light three-dimensional morphology rapid measuring algorithm

A technology of three-dimensional shape and short coherent light, which is applied in the direction of measurement devices, calculations, and optical devices, can solve problems such as long running time of algorithms, reduce overall running time, improve measurement accuracy and reliability, shorten time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

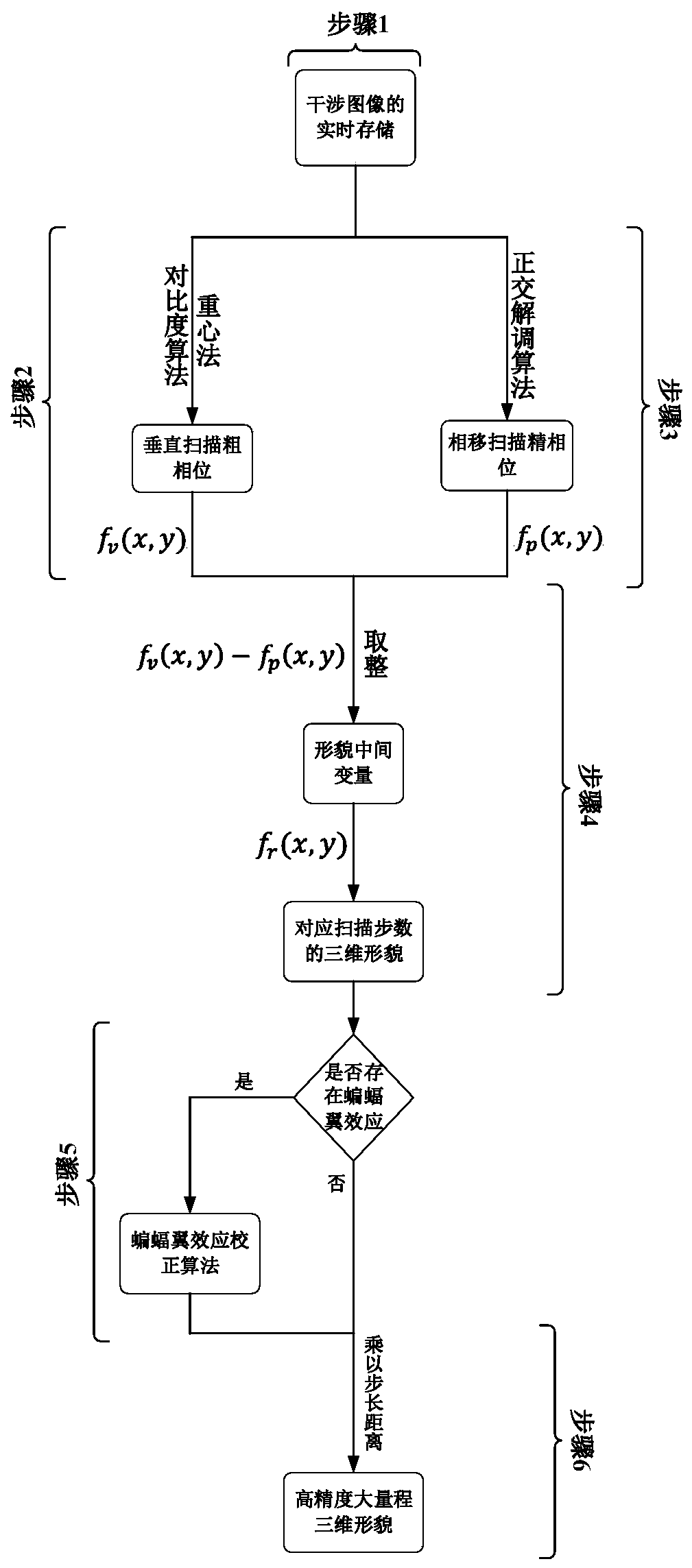

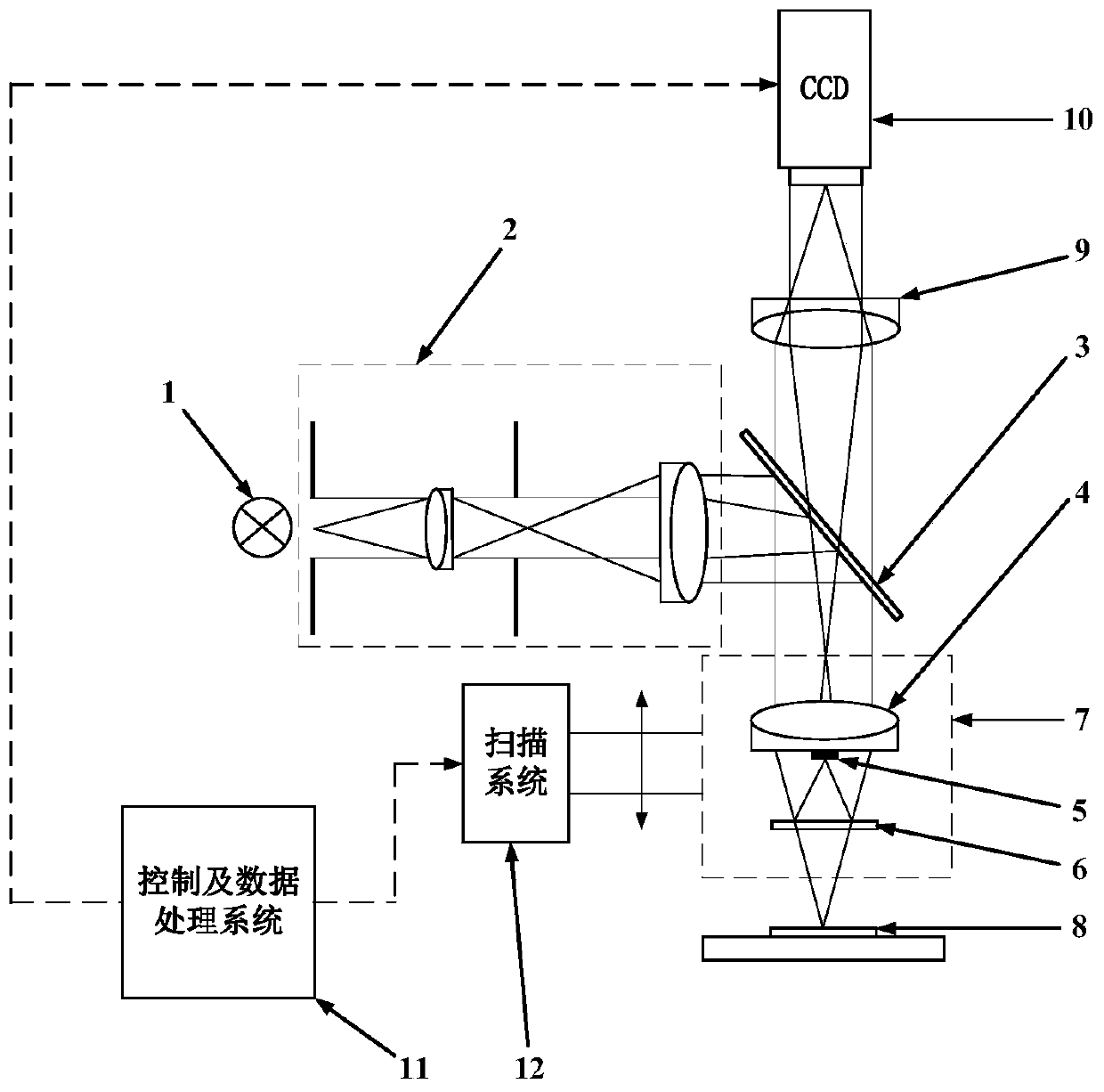

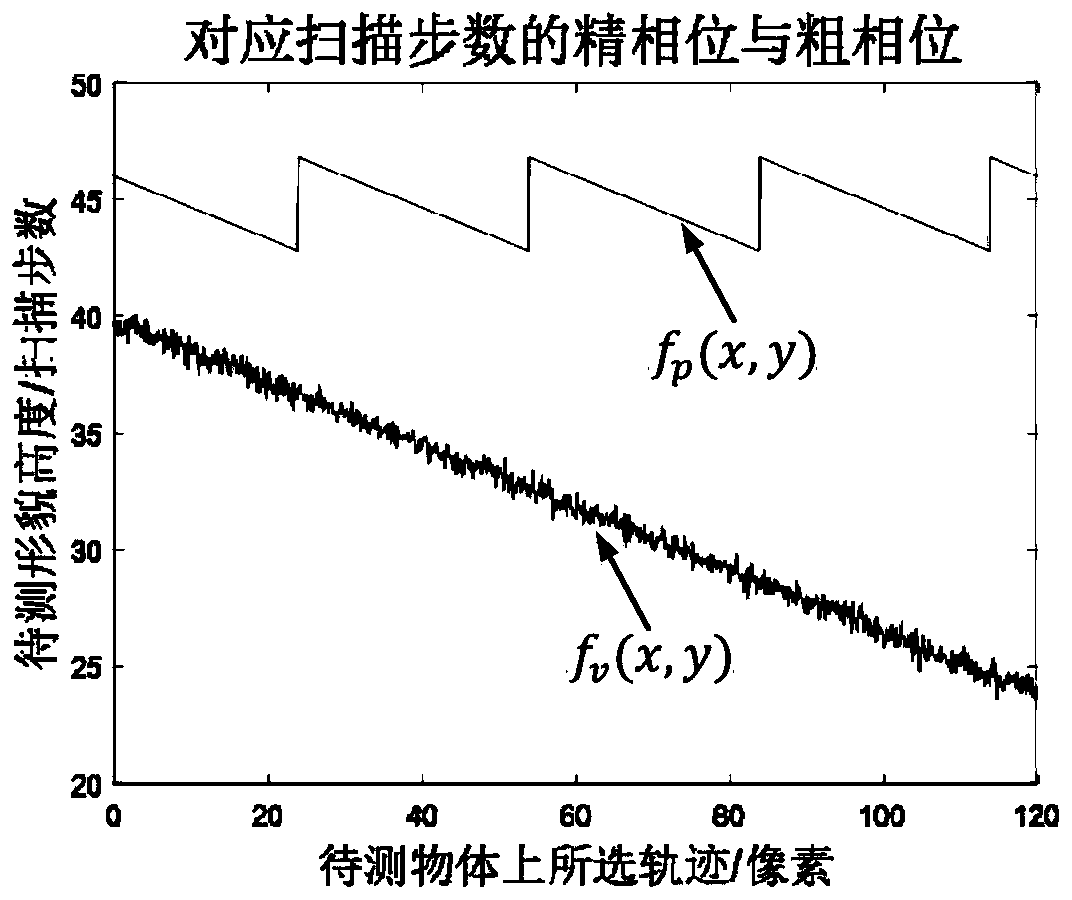

[0049] combine Figure 1 to Figure 8 , a high-precision short-coherent light three-dimensional fast shape measurement algorithm. During the experiment, the optical system is equipped with an interference objective lens system with a magnification of 20×. The light source uses short-coherent light with a central wavelength of 576nm. The sample with the same shape is detected, and its step height is 332nm. The control and data processing system controls the scanning system to collect 120 within the total scanning length of 8.64μm according to the phase step of π / 2 (the corresponding step distance is 72nm). Interferometric images are calculated. The implementation steps of the high-precision short-coherent light three-dimensional shape fast measurement algorithm proposed in this patent are as follows:

[0050] Step 1. Combine figure 2 As shown in the schematic diagram of the optical path structure, connect the light source to the lighting system, adjust the spatial position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com