Underground diaphragm wall with anti-seepage joints and construction method of underground diaphragm wall

A technology for underground diaphragm walls and joints, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of punching shear damage, insufficient joint stiffness, long welds, etc., and achieve the effect of enhancing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

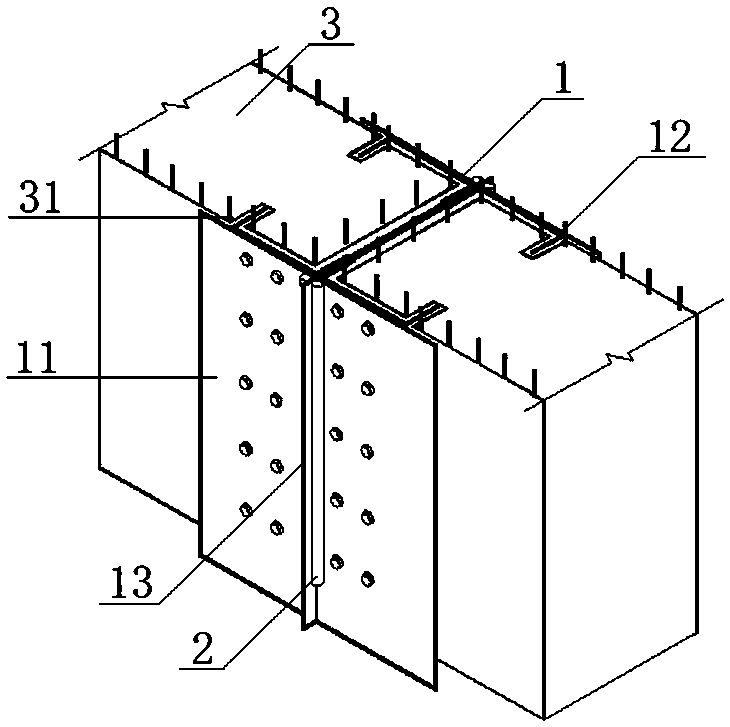

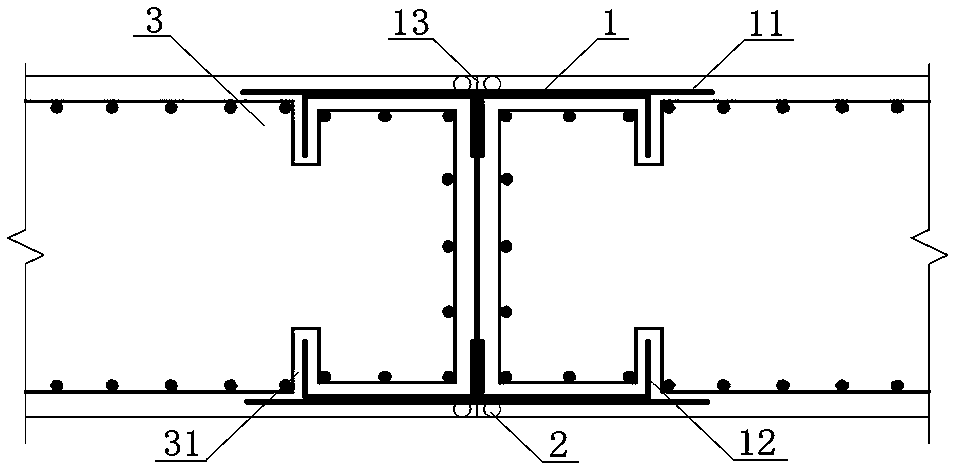

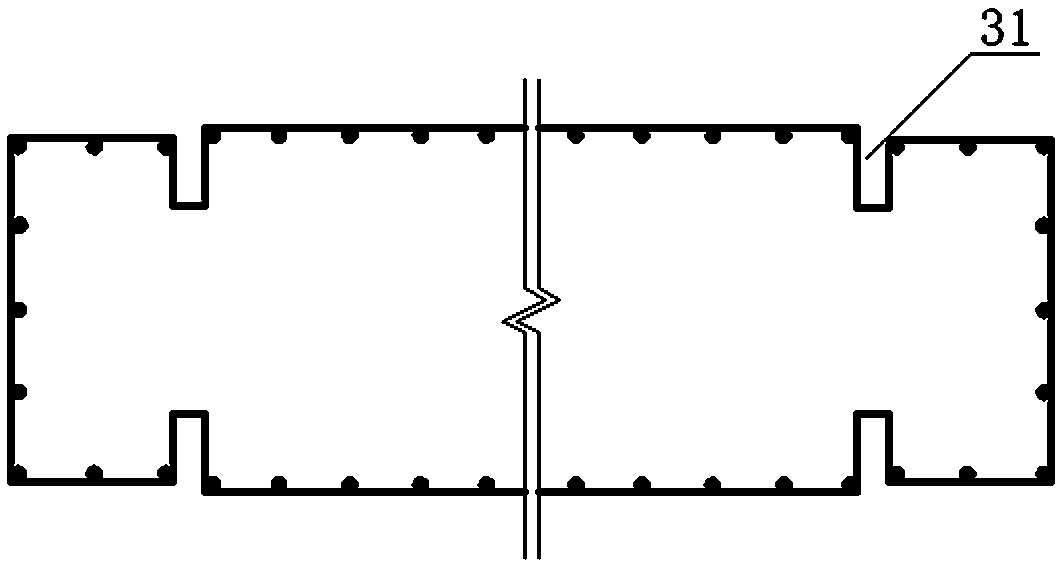

[0035] An underground continuous wall with anti-seepage joints, including a wall structure formed by pouring concrete from a steel cage 3, and an anti-seepage joint 1 connecting the adjacent wall structures;

[0036] The anti-seepage joint 1 includes I-shaped steel 11, the I-shaped steel 11 is vertically arranged in the groove, the I-shaped steel web 112 is located at the joint of the adjacent reinforcement cage 3, and the I-shaped steel flanges on both sides The horizontal direction of 111 is consistent with the horizontal extension direction of the wall structure, and the vertical direction is consistent with the longitudinal extension direction of the wall structure;

[0037] The outer sides of the I-steel flanges 111 on both sides correspond to the I-steel webs 112 and are respectively provided with waterproof steel plates 13, and each water-sealed steel plate 13 is perpendicular to the I-steel flanges 111, and the arrangement direction is the same as that of the I-steel we...

Embodiment 2

[0041] A construction method for an underground diaphragm wall with anti-seepage joints, comprising the following steps:

[0042] (1) The trench for the underground diaphragm wall shall be dug in advance, and the side wall and bottom of the trench shall be as smooth and clean as possible.

[0043](2) Connect the I-beam 11 and the channel steel 12 together by bolts, and then weld the water-stop steel plate 13 on the outside of the I-beam flange 111 on both sides corresponding to the I-beam web 112, and the I-beam 11. The channel steel 12 and the waterproof steel plate 13 constitute the anti-seepage joint 1 .

[0044] (3) Hang the anti-seepage joint 1 vertically in the trench. The depth of the bottom of the anti-seepage joint 1 inserted into the soil layer is 30cm. The trench is divided into two sections on the left and right. The two slot sections of the are completely separated;

[0045] The grouting pipes 2 are respectively arranged on both sides of the water-stop steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com