Application of heat phase change heat storage material in movable multifunctional heat storage device

A heat storage material and heat storage device technology, applied in the direction of heat exchange materials, heat storage equipment, heat exchanger types, etc., can solve the problems of waste heat waste, low energy utilization level, etc., and achieve efficient heat output and storage. Transfer and utilization, the effect of excellent phase change heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

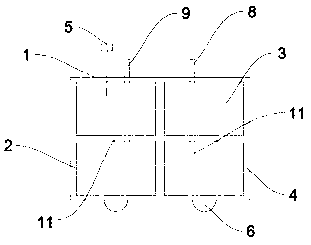

[0038] like figure 1 As shown, this embodiment provides a mobile multifunctional heat storage device, which includes an outer shell 1, an inner shell 2, an insulation layer 4, four heat storage units 3 of thermal phase change heat storage materials, and a temperature measuring device 5 And the sliding buckle6. The outer casing 1 and the inner casing 2 are nested with each other, and the heat insulation layer 4 is arranged between the outer casing 1 and the inner casing 2 to prevent heat loss of the movable multifunctional heat storage device. Four heat storage units 3 of thermal phase change heat storage materials are evenly distributed in the inner casing 2 with gaps between them. The temperature measuring device 5 is connected with the heat storage unit 3 of the thermal phase change heat storage material, and is used for detecting the temperature of the heat storage unit 3 of the thermal phase change heat storage material. The sliding buckle 6 is arranged on the outer side...

Embodiment 2

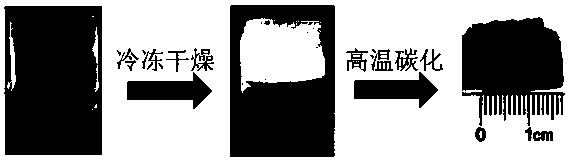

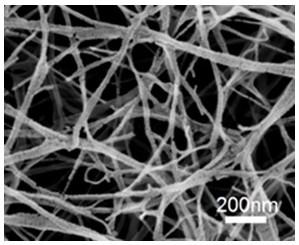

[0047] 1) Preparation of porous bacterial cellulose: Cut the bacterial cellulose BC soaked in deionized water to pH = 7 into small pieces (about 1×1cm), clean the pieces and put them in the refrigerator to freeze and freeze-dry 24 h. The obtained samples were placed in a tube furnace under N 2 Under protected conditions, the temperature was programmed to heat carbonization, and the temperature was raised to 350 °C at a rate of 1.5 °C / min for 1 h, and then the temperature was raised to 800 °C at a rate of 3 °C / min for 2 h to obtain porous bacterial cellulose . The schematic diagram of its preparation process is shown in figure 2 As shown, the electron micrograph of porous bacterial cellulose after high temperature carbonization is as follows image 3 shown.

[0048] 2) Weigh 0.5 gBa(OH) 2 ·8H 2 O into the cup, add a small amount of deionized water (the deionized water is just enough to wet the solid particles), and then heat it in a common box at 80°C for 2 hours to make...

Embodiment 3

[0050] 1) Preparation of porous bacterial cellulose: Cut the bacterial cellulose BC soaked in deionized water to pH = 7 into small pieces (about 1×1cm), clean the pieces and put them in the refrigerator to freeze and freeze-dry 24 h. The obtained samples were placed in a tube furnace under N 2 Under protected conditions, the temperature was programmed to heat carbonization, and the temperature was raised to 350 °C at a rate of 1.5 °C / min for 1 h, and then the temperature was raised to 800 °C at a rate of 3 °C / min for 2 h to obtain porous bacterial cellulose .

[0051] 2) Weigh 0.5 g Na 2 SO 4 ・10H 2 O is put into the cup, add a small amount of deionized water (the deionized water is just enough to wet the solid particles), and then heat it at 80 ° C for 2 hours in a common box to make Na 2 SO 4 ・10H 2 O was completely melted, then 0.08 g of surfactant OP-10 was added, and ultrasonically dispersed for 30 min to form a stable emulsion. Add 0.5 g of porous bacterial cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com