High-gloss piano-black PA/PMMA alloy resin composition and preparation method thereof

A technology of alloy resin and piano black, which is applied in the field of high-gloss piano black PA/PMMA alloy resin composition and its preparation, can solve the problems of opaque alloy and inability to obtain piano black materials, and achieve improved compatibility and excellent scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of high-gloss piano black PA / PMMA alloy resin composition adopts the following steps:

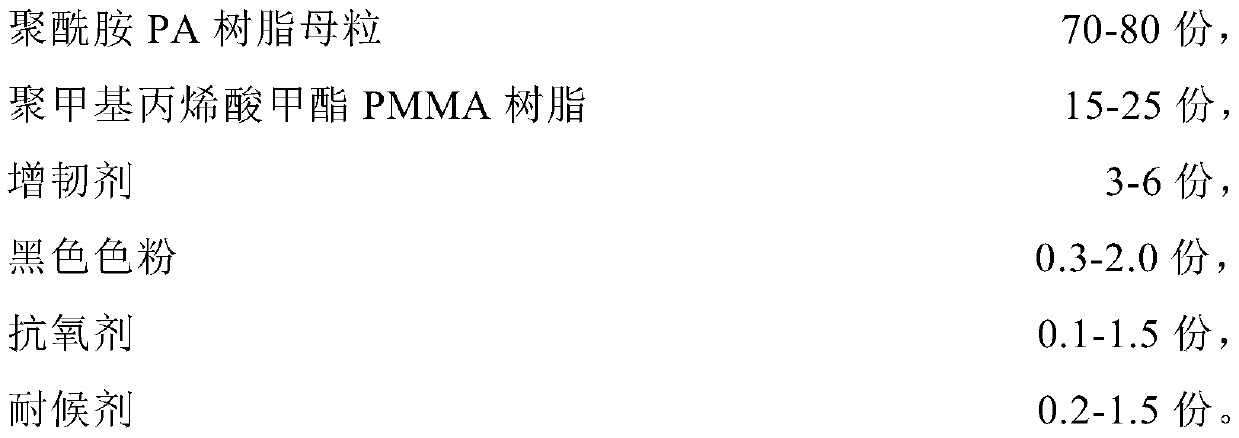

[0044] (1) Weigh 70-80 parts of PA resin masterbatch, 15-25 parts of PMMA resin, 3-6 parts of toughening agent, 0.3-2.0 parts of black toner, 0.1-1.5 parts of antioxidant, weather resistance 0.2-1.5 parts of the agent, mixed evenly to obtain the premix;

[0045] (2) Put the premixed material into a twin-screw extruder, control the extrusion temperature to 230-260° C., and carry out melt extrusion at a screw speed of 200-500 rpm, cool and granulate to obtain the target product.

[0046] The following are more detailed implementation examples, through which the technical solutions of the present invention and the technical effects that can be obtained are further described.

Embodiment 1

[0048] The present embodiment provides a kind of high-gloss piano black PA / PMMA alloy resin composition, and its raw material composition is as follows:

[0049] Composition of PA resin masterbatch:

[0050] PA6I / 6T 90 copies

[0051] Compatibilizer (St:MMA:MAH=30:50:20) 10 parts

[0052] Antioxidant 1 part

[0053] Target product composition:

[0054]

Embodiment 2

[0056] The present embodiment provides a kind of high-gloss piano black PA / PMMA alloy resin composition, and its raw material composition is as follows:

[0057] Composition of PA resin masterbatch:

[0058] PA6I / 6T 90 copies

[0059] Compatibilizer (St:MMA:MAH=30:60:10) 10 parts

[0060] Antioxidant 1 part

[0061] Target product composition:

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com