Suspension type single track vehicle traction suspension device applied to large ramp and method

A vehicle traction and suspension device technology, which is applied in the direction of the lateral relative movement device between the underframe and the bogie to achieve the effects of improving load distribution, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

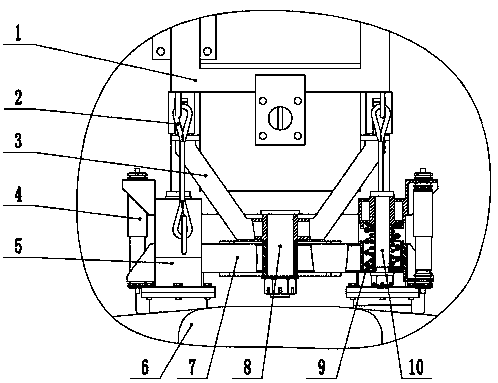

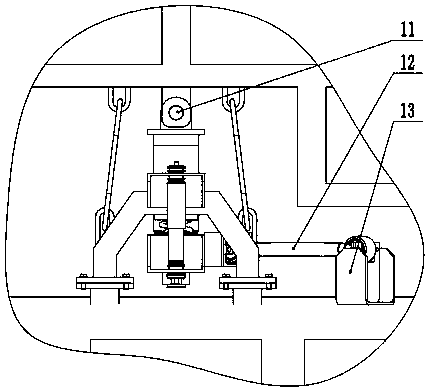

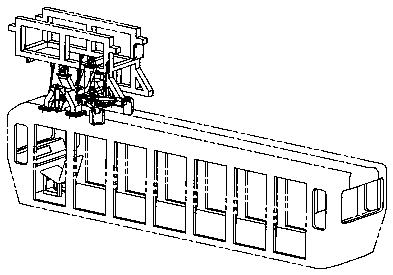

[0012] Embodiment 1: with reference to attached Figure 1-3 . A suspension type monorail vehicle traction suspension device suitable for large ramps, characterized in that: the U-shaped beam 3 is connected with the crossbeams on both sides of the bogie frame 1 using pin shafts 11, and the bottom of the U-shaped beam 3 is provided with pin holes. The middle vertical shaft 8 connects the U-shaped beam 3 with the bolster 7, two sets of shock absorbers 4 and shock absorbing springs 9 are symmetrically arranged on both sides of the bolster 7, the lower end of the shock absorber 4 is installed with the bolster 7, and the shock absorber 4 The upper end is installed with the suspension beam 5, and the damping spring 9 is installed in the bolster 7 and the suspension beam 5 respectively by the shock-absorbing connecting shaft 10, and the suspension beam 5 is installed with the mounting seat corresponding to the car body 6. The bolster 7 is provided with a drawbar mounting seat, the dr...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a kind of working method of suspension type monorail vehicle traction suspension device, U-shaped beam 3 and bogie frame 1 both sides beams are connected by pin shaft 11, U-shaped beam 3 can be wound around Bearing pin 11 rotates back and forth, and the load transmitted to bogie frame 1 by pin 11 under any slope has only power like this, does not have front and rear bending moment. Improved load distribution to bogie load wheels. The bolster 7 is connected with the U-shaped beam 3 using an intermediate vertical shaft 8, and the connecting hole between the intermediate vertical shaft 8 and the bolster 7 and the U-shaped beam 3 adopts clearance fit, and the lower end of the intermediate vertical shaft 8 is fixed with a lock nut. In this way, the bolster 7 and the U-shaped beam 3 can rotate around the middle vertical shaft 8, and the middle vertical shaft 8 transmits axial load, left and right and front and rear bending moments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com