Bending Correction Method of Column and Bed of Machine Tool

A column and bed technology, which is applied in the field of bending correction of the column and bed of the machine tool, can solve the problems of inability to accurately detect the amount of bending, complex structure, etc., and achieve the effects of improving the reliability of correction, simplifying the structure, and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

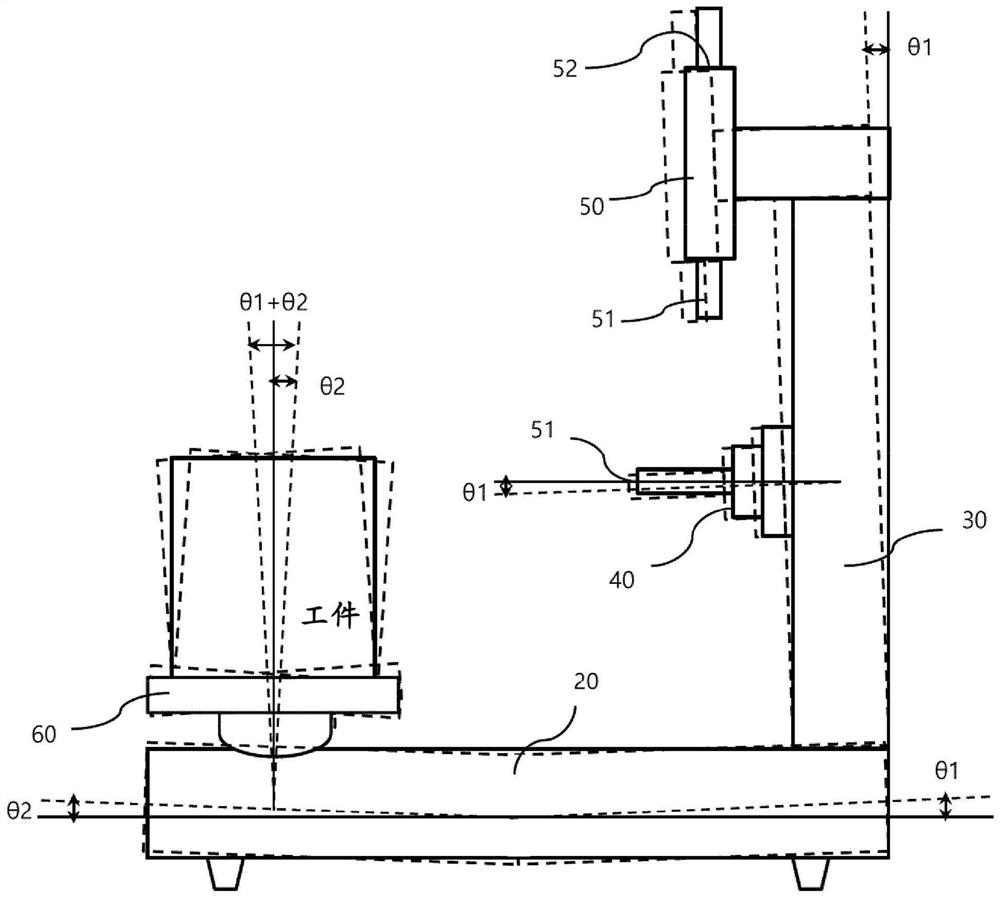

[0029] The following is combined with the attached Figure 1 to Figure 5 Preferred embodiments of the present invention will be described.

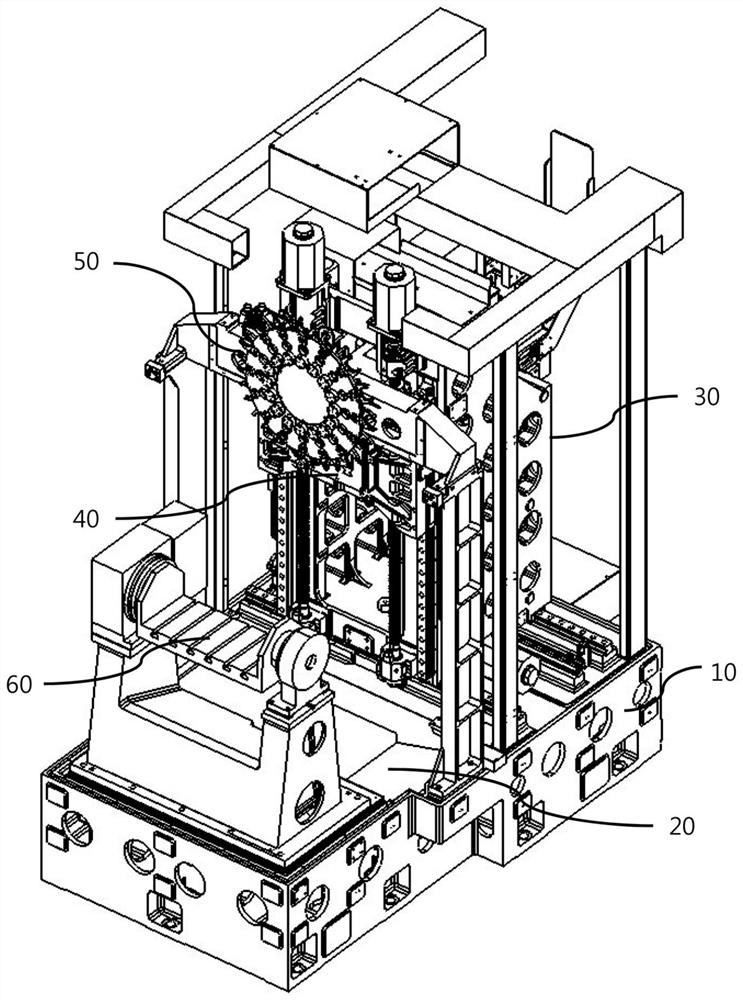

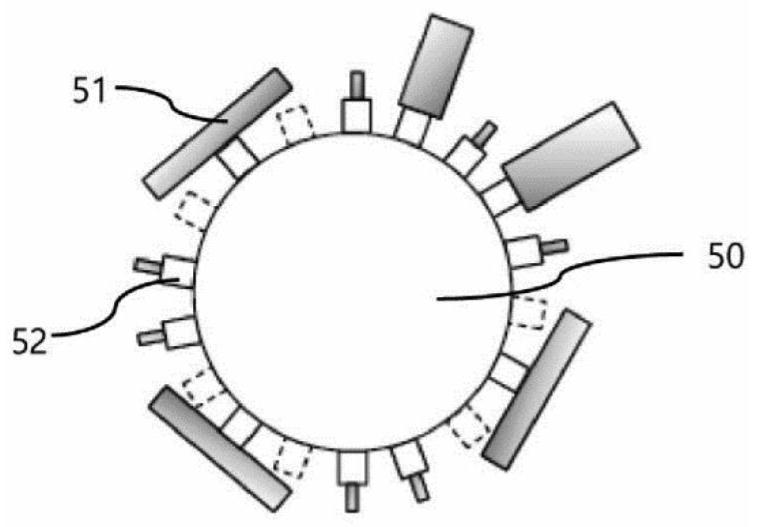

[0030] First, if figure 1 As disclosed, the present invention has a vertical column 30 extending from the machine tool body 10, a tool magazine 50 fixedly arranged on the front upper end of the column 30 along the direction of the processing area, and a tool magazine 50 fixed on the front upper end of the column 30 along the direction of the processing area on the machine tool body 10. The bed 20 at the front lower end of the column 30 is provided at a position facing the column 30 on the bed 20 and is tilted in the front-rear direction so as to be spaced apart from the column 30 . The workbench 60, and the control device that controls the various moving parts or parts of the machine tool.

[0031] The correction of the amount of bending of the bed 20 and the column 30 of the present invention is mainly performed by the control program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com