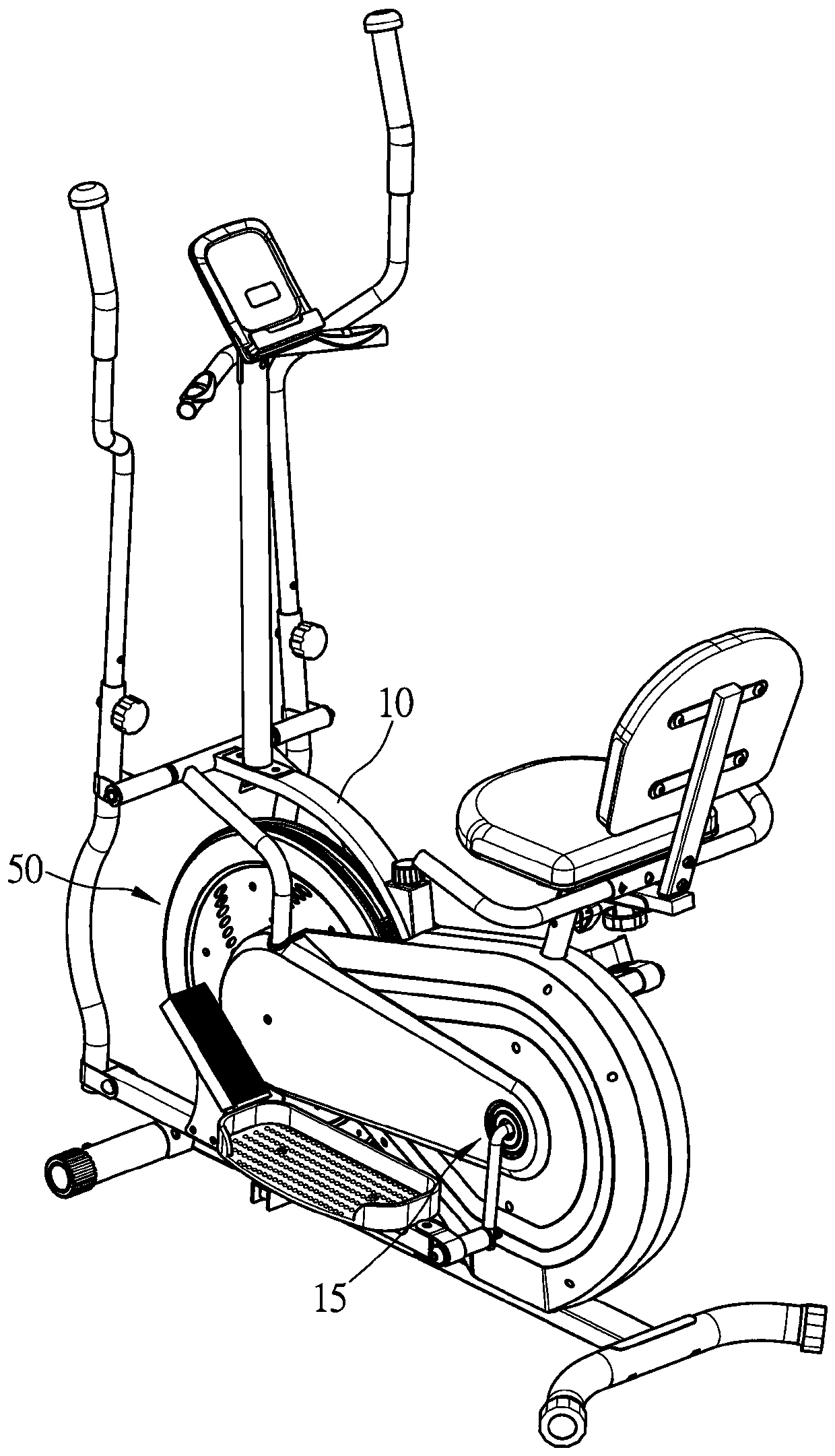

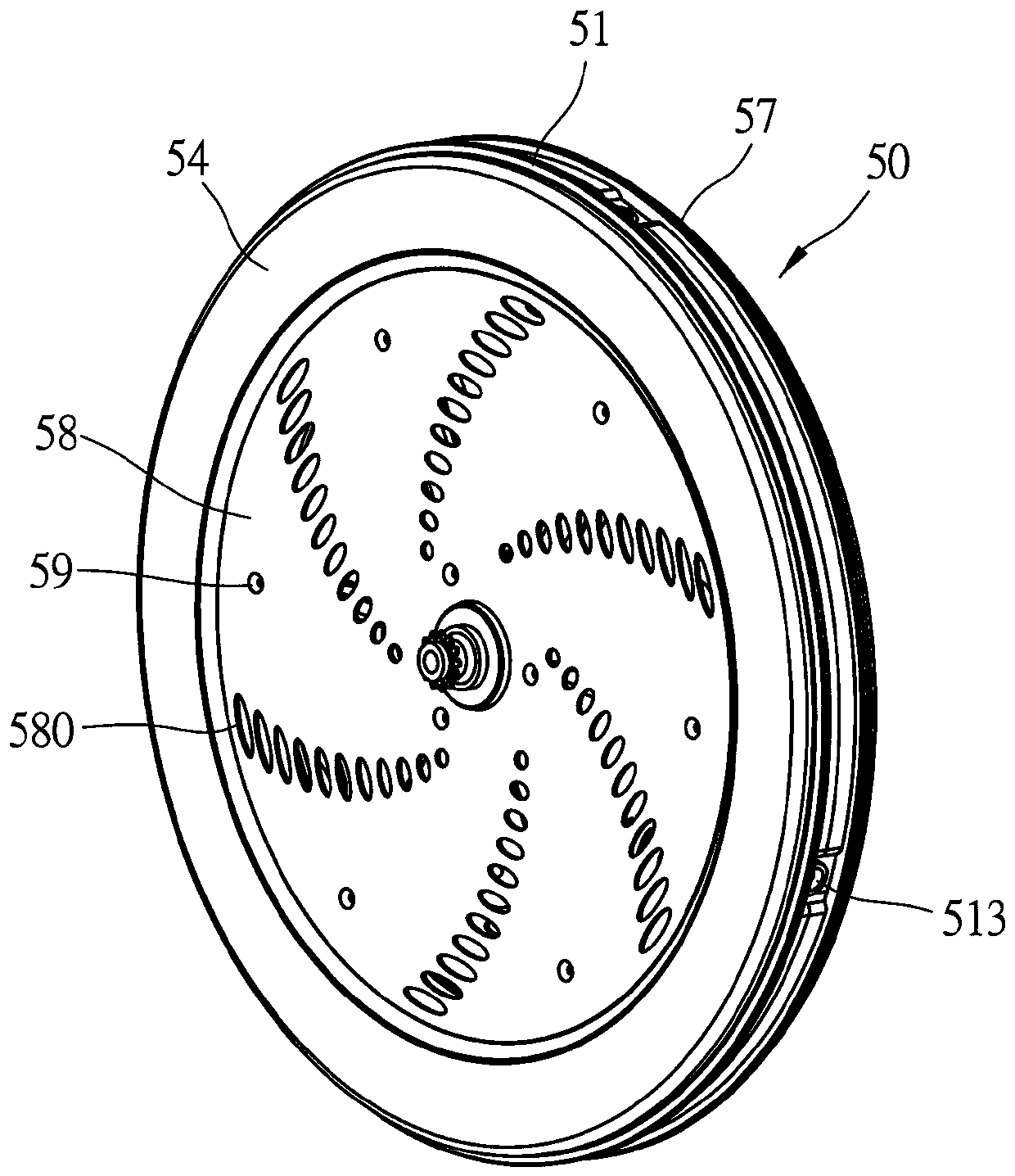

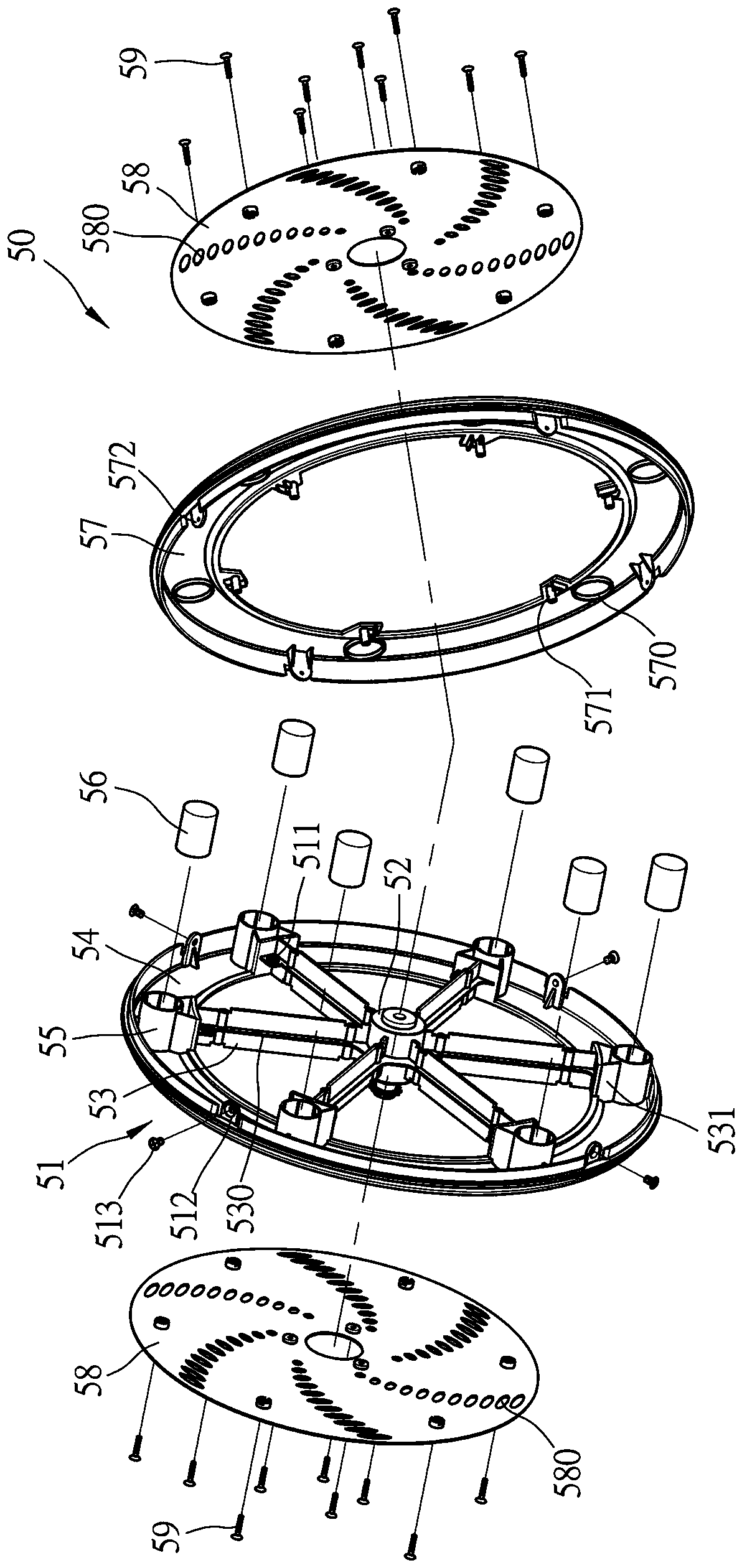

Flywheel structure

A technology of flywheels and axles, applied in sports accessories, muscle training equipment, gymnastics equipment, etc., can solve the problems of not easy to generate inertia, lack of inertia and balance, increase inertia, etc., reduce the probability of damage, improve exercise effect, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the structure, features and other purposes of the present invention, the preferred embodiments of the present invention are listed below, and are described in detail with reference to the drawings, so that those skilled in the art can implement them.

[0040] The present invention is a flywheel structure. In the specific embodiments of the present invention and its components illustrated in the accompanying drawings, all references to front and rear, left and right, top and bottom, upper and lower, and horizontal and vertical are only It is used for convenience of description, and does not limit the invention, nor restrict its components to any position or orientation in space. The dimensions specified in the drawings and description can be changed according to the design and requirements of the specific embodiments of the present invention without departing from the patent scope of the present invention.

[0041] And about the detailed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com