Filter bed breeding system and factory breeding method of buried-dwelling marine organisms

The technology of a breeding system and breeding method is applied in the field of aquaculture to achieve the effects of improving bed efficiency, accelerating oxidative decomposition, and increasing oxidative decomposition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

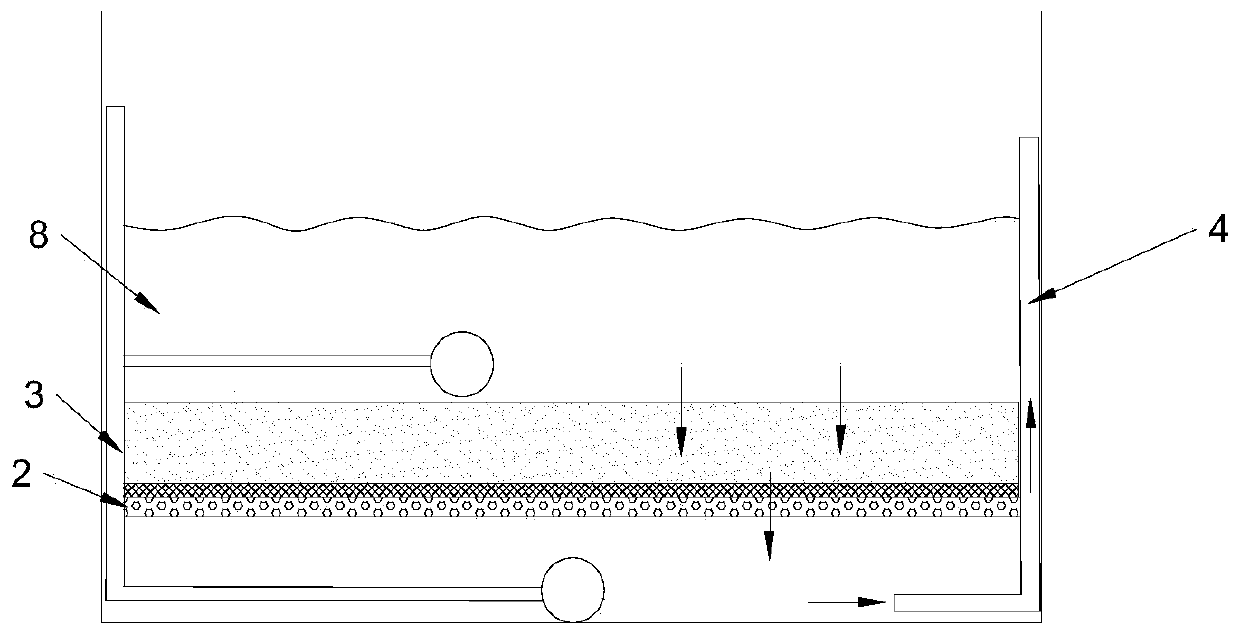

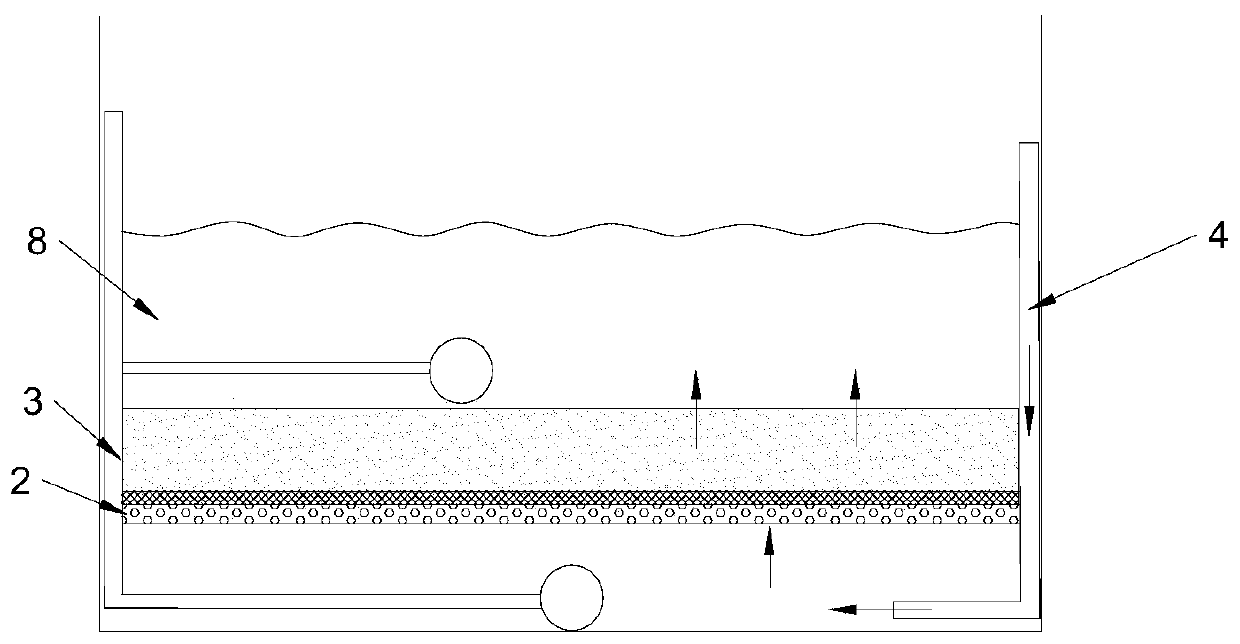

[0026] Such as figure 1 As shown, the filter bed type cultivation system of the present invention includes a cultivation pond 1, and the area of the cultivation pond 1 can be set according to actual needs, with an area of 5 to 100m 2 , the bottom of the culture pond 1 is provided with an overhead layer 2, on which the sand filter bed 3 is laid, and above the sand filter bed 3 is an aquaculture water layer 8; the culture pond 1 is provided with an air lift pipe 4, so One end of the airlift pipe 4 is connected to the bottom of the culture pond 1, and the other end of the airlift pipe 4 is connected to the top of the culture water layer 8; the bottom of the culture pond 1 is provided with the first aeration pipe 5, and the bottom of the culture water layer 8 There is a second oxygen increasing pipe 6, and the two together form a three-dimensional oxygen increasing system. The first oxygen increasing pipe 5 passes through the sand filter bed 3 through the PVC pipe 7 and is con...

Embodiment 2

[0032] Embodiment 2: Shrimp enters the pond and increases oxygen.

[0033] Put prawns in the filter bed culture system, the size is 3-4cm, and the density is 100-300 tails / m 2 , The shrimp at this time has the habit of diving into the sand, and the compound feed is fed at 6% of the feeding amount.

[0034] During oxygenation, the oxygenation and disturbance of the overhead layer 2 can prevent the water body below the overhead layer 2 from forming a still water dead angle; the dissolved oxygen in the aquaculture water layer 8 can reach more than 5mg / L, and sufficient oxygenation will help the water body (including overhead) Oxidative decomposition of organic matter in the water body below layer 2).

[0035] In addition, open the airlift pipe 4, due to the rising water effect of the airlift pipe 4, dissolved oxygen in the water body of the culture water layer 8 enters the sand layer 31 and makes the sand layer 31 an oxygen-enriched sand layer, avoiding the formation of an anaerob...

Embodiment 3

[0036] Example 3: Adhesion and efficient decomposition of probiotics.

[0037] Probiotics such as bacillus, lactic acid bacteria and photosynthetic bacteria are added to the culture pond 1. When the filter bed culture system is running, the probiotics in the culture water layer 8 are continuously infiltrated into the sand layer 31, which improves the adhesion efficiency of the probiotics , so that the sand layer filter bed 3 becomes a probiotic bed; at the same time, the attached probiotics degrade and utilize the residual bait and feces through biodegradation, promote the proliferation of probiotics, increase the stabilization effect of the probiotic bed, and improve the decomposition efficiency of the residual bait and feces. Avoid sand blackening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com