Liquid cooling radiators and server system

A radiator and liquid cooling technology, which is applied to indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve problems such as large temperature difference, reduced heat dissipation performance of water-cooled plates, and reduced overall heat dissipation performance of liquid-cooled radiators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

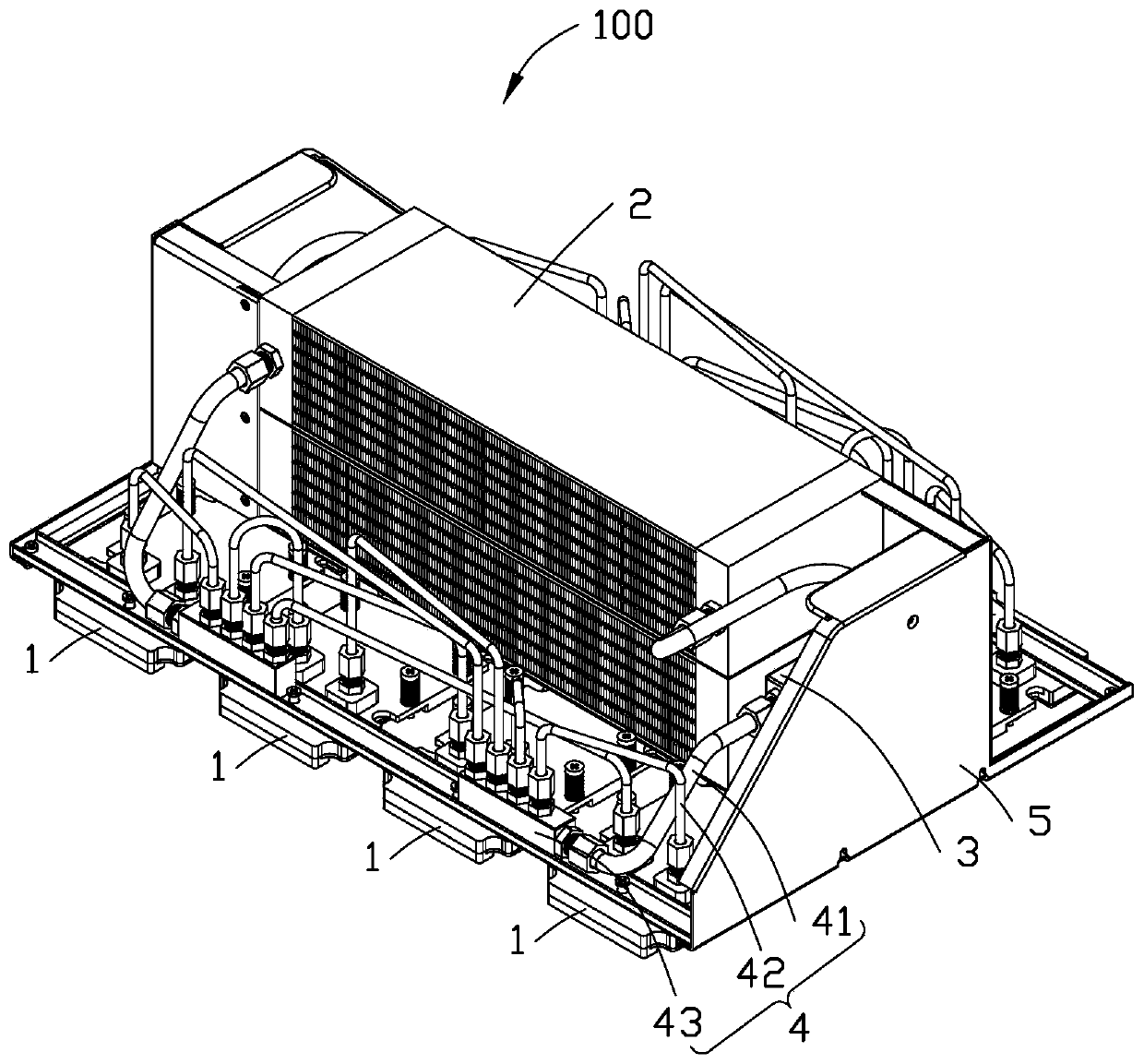

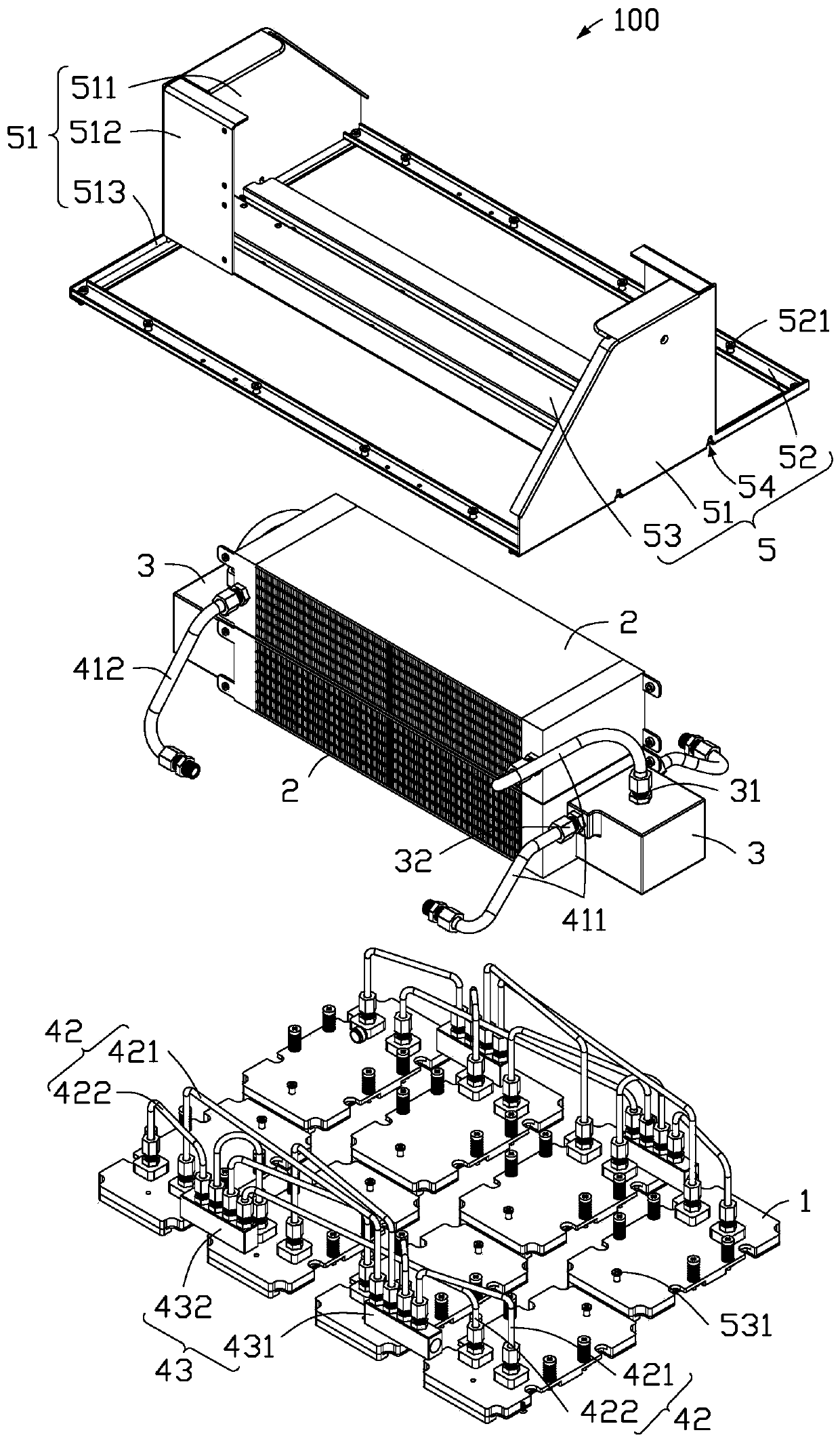

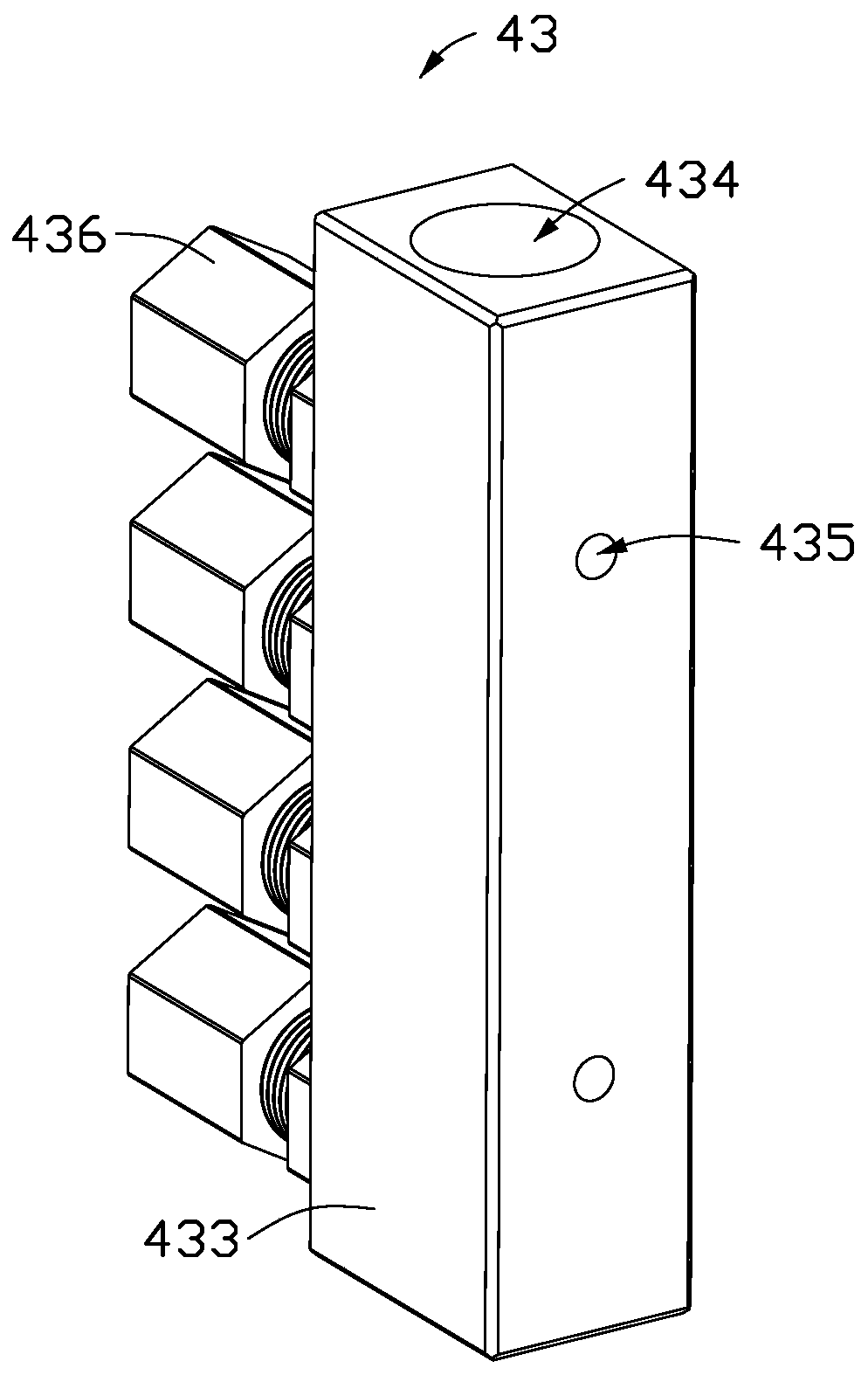

[0080] see figure 1 with Figure 9 , the server system 600 includes a plurality of electronic chips 61 , and the liquid cooling radiator 100 is used for dissipating heat from the plurality of electronic chips 61 in the server system 600 . The liquid cooling radiator 100 includes a plurality of water cooling plates 1 , a condenser 2 , a driver 3 , a cooling liquid pipe assembly 4 and a mounting bracket 5 . The plurality of water cooling plates 1 and the condenser 2 are fixedly arranged on the installation bracket 5 . The driver 3 is respectively connected to the plurality of water cooling plates 1 and the condenser 2 through the cooling liquid pipe assembly 4 . The cooling liquid pipeline assembly 4 includes a main pipeline 41 , branch pipelines 42 and distribution blocks 43 . The splitter block 43 is also fixedly arranged on the installation bracket 5 . The plurality of water cooling plates 1 are connected in parallel to the distribution block 43 through the branch pipe 42...

Embodiment 2

[0094] see Figure 7 with Figure 8 The liquid-cooled radiator 200 of the second embodiment is substantially the same as the liquid-cooled radiator 100 of the first embodiment, the difference is that the liquid-cooled radiator 200 of the second embodiment has a set of water-cooled plates 1A, a condenser 2A, a driver 3A and A set of coolant pipe assemblies 4A. The structure and function of the liquid cooling radiator 200 will not be repeated here.

[0095] It can be understood that in other embodiments, the number of water-cooled plate 1, condenser 2, driver 3 and coolant pipe assembly 4 can be increased or decreased in multiples according to the actual situation, and is not limited to the situation of embodiment 1 and embodiment 2 .

[0096] The liquid-cooled radiator 100 connects multiple water-cooled plates 1 to the condenser 2 in parallel, uses a driver 3 to provide power for multiple water-cooled plates 1, and sends cooling liquid of the same temperature to multiple wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com