Calculation of fuel cell system and combustion coefficient and judging method of combustion degree

A fuel cell system and combustion chamber technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of low material utilization rate and difficult control of fuel cell combustion, so as to achieve difficult judgment errors, simple judgment methods, and sufficient combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

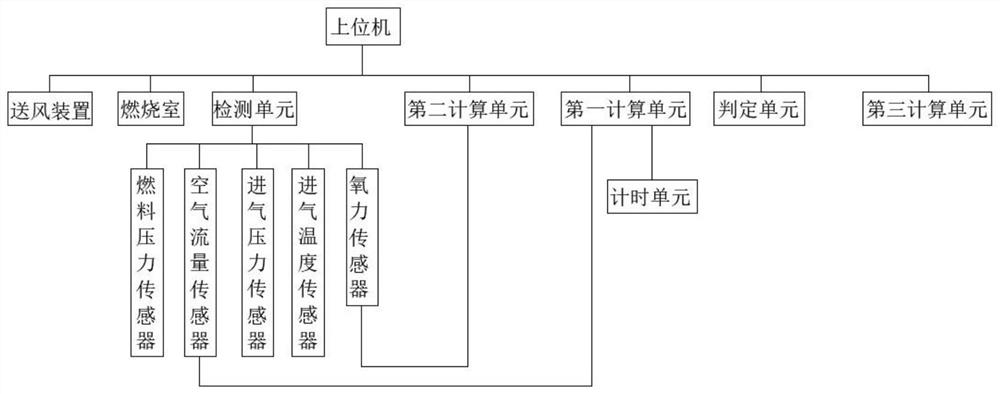

[0057] A fuel cell system comprising:

[0058] The combustion chamber receives the reaction gas delivered by the air supply device, and the reaction gas is used to provide energy for combustion in the combustion chamber;

[0059] The detection unit includes a fuel pressure sensor, an air flow sensor, an intake air pressure sensor, an intake air temperature sensor and an oxygen sensor; wherein,

[0060] The fuel pressure sensor is used to detect the pressure in the combustion chamber; the air flow sensor is used to detect the flow rate of the reactive gas delivered by the air supply device; the intake pressure sensor is used to detect the pressure of the reactive gas; the intake air temperature sensor is used to detect the temperature of the reactiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com