Manufacturing method of high-voltage cable in new energy vehicle

A technology for cable manufacturing and new energy vehicles. It is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, and circuits. It can solve the problems of single cable varieties, fierce market competition, and numerous manufacturers, and achieve high interference resistance. The shielding effect is stable and the effect of increasing the variety of models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

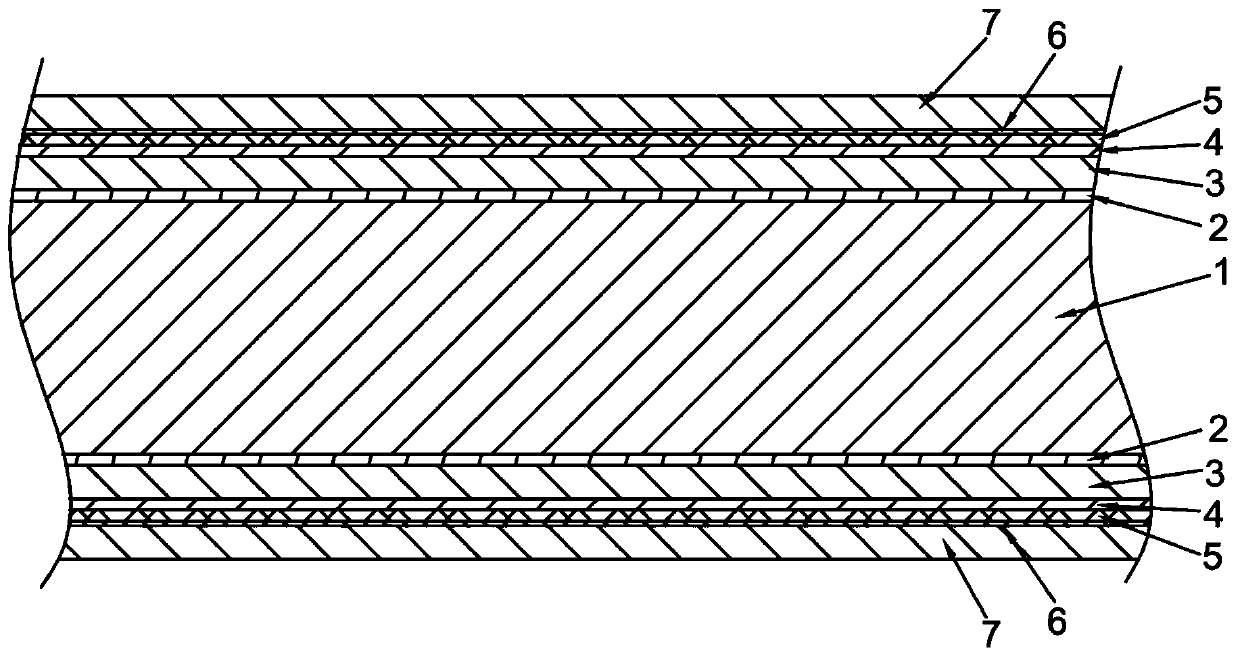

[0031] In the first step, taking the conductor 1 as the center, a semi-conductive nylon tape 2, a cross-linked polyethylene insulating layer 3, and a semi-conductive shielding layer 4 are sequentially wrapped around it to form an insulating core. The cross-linked polyethylene insulating layer 3. The semi-conductive shielding layer 4 adopts a double-layer co-extrusion method and is extruded with a semi-extrusion die. The material components of the semi-conductive shielding layer 4 include nano-MgO and nano-Al 2 o 3 , nano-SiC;

[0032] In the second step, the braided shielding layer 5 and the flame-retardant PET tape 6 are sequentially coated on the outside of the insulated wire core;

[0033] The third step is to use a semi-extrusion die to extrude the flame-retardant PET tape 6 and set the cross-linked polyethylene outer sheath 7 to form a pre-finished cable;

[0034] The fourth step is to use the dry cross-linking method to continuously and evenly pass the pre-finished cab...

Embodiment 2

[0038] In the first step, taking the conductor 1 as the center, a semi-conductive nylon tape 2, a cross-linked polyethylene insulating layer 3, and a semi-conductive shielding layer 4 are sequentially wrapped around it to form an insulating core. The cross-linked polyethylene insulating layer 3. The semi-conductive shielding layer 4 adopts a double-layer co-extrusion method and is extruded with a semi-extrusion die. The material components of the semi-conductive shielding layer 4 include nano-MgO and nano-Al 2 o 3 , nano-SiC;

[0039] In the second step, the braided shielding layer 5 and the flame-retardant PET tape 6 are sequentially coated on the outside of the insulated wire core;

[0040] The third step is to use a semi-extrusion die to extrude the flame-retardant PET tape 6 and set the cross-linked polyethylene outer sheath 7 to form a pre-finished cable;

[0041] The fourth step is to use the dry cross-linking method to continuously and evenly pass the pre-finished cab...

Embodiment 3

[0045] In the first step, taking the conductor 1 as the center, a semi-conductive nylon tape 2, a cross-linked polyethylene insulating layer 3, and a semi-conductive shielding layer 4 are sequentially wrapped around it to form an insulating core. The cross-linked polyethylene insulating layer 3. The semi-conductive shielding layer 4 adopts a double-layer co-extrusion method and is extruded with a semi-extrusion die. The material components of the semi-conductive shielding layer 4 include nano-MgO and nano-Al 2 o 3 , nano-SiC;

[0046] In the second step, the braided shielding layer 5 and the flame-retardant PET tape 6 are sequentially coated on the outside of the insulated wire core;

[0047] The third step is to use a semi-extrusion die to extrude the flame-retardant PET tape 6 and set the cross-linked polyethylene outer sheath 7 to form a pre-finished cable;

[0048] The fourth step is to use the dry cross-linking method to continuously and evenly pass the pre-finished cab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com