Ion source filamentworking method

A working method and ion source technology, applied in the field of mass spectrometry analysis, can solve the problems of inaccurate measurement of instruments, excessive filament current, waste, etc., and achieve the effect of accurate replacement time and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

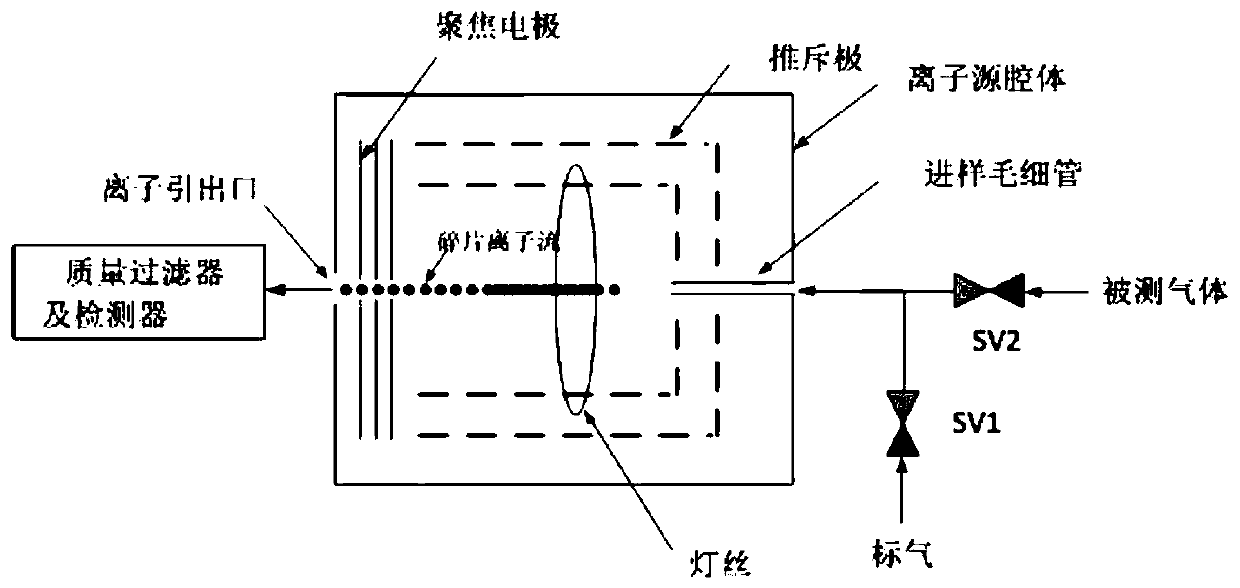

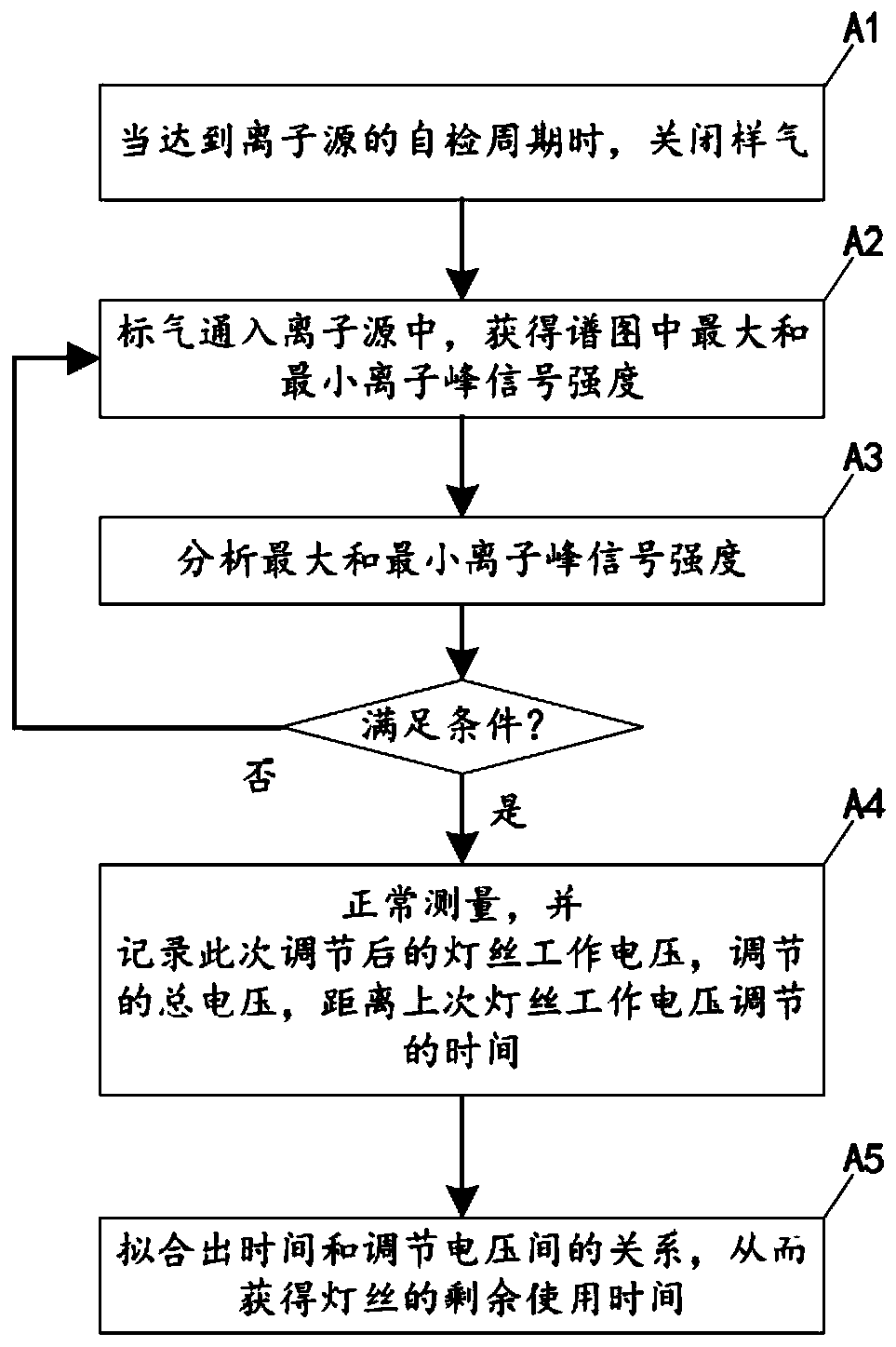

[0028] figure 2 A flow chart of the working method of the ion source filament in the embodiment of the present invention is schematically given, as figure 2 As shown, the working method of the ion source filament comprises the following steps:

[0029] (A1) When the self-test cycle of the ion source is reached, the sample gas is turned off; the ion source is an EI source;

[0030] (A2) The standard gas is passed into the ion source to obtain the maximum ion peak signal intensity I in the spectrogram max , the minimum ion peak signal intensity I min ;

[0031] (A3) Analytical ion peak signal intensity I max , I min :

[0032] If I max ≤I s , and the signal strength I min When the signal-to-noise ratio is greater than N, end the self-inspection and enter step (A4); s is the upper limit of ion peak intensity;

[0033] If I max ≤ I s , and the signal strength I min When the signal-to-noise ratio is less than N, increase the working voltage U of the filament, U≤U m...

Embodiment 2

[0040] An application example of the working method of the ion source filament according to Embodiment 1 of the present invention.

[0041] In this application example, the ion source adopts EI source, and the initial working voltage of the filament is U 0 , in step (A3), the working voltage of the filament is increased by Δu each time, that is, the step size of the increase is Δu. It can be seen that in each self-test, if the working voltage of the filament is to be adjusted, each self-test The working voltage of the filament adjusted in ΔU=K·Δu, K is a positive integer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com