Waste gas treatment device for chemical raw material production

A technology for waste gas treatment devices and chemical raw materials, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as troublesome treatment, increased cost of activated carbon replacement, and excessive particulate matter, and achieves improved contact and accurate replacement time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

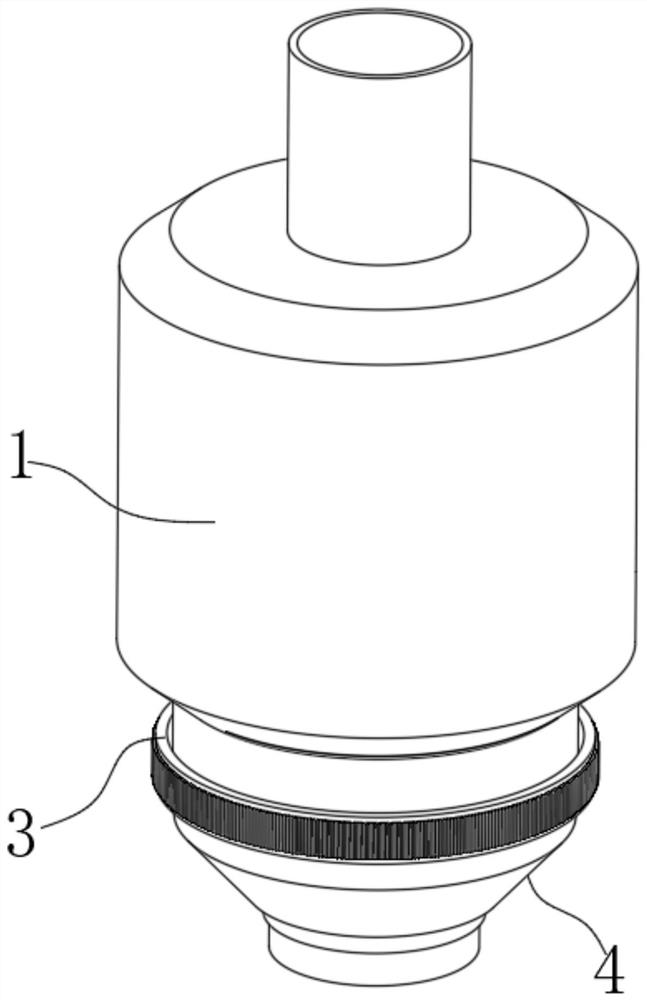

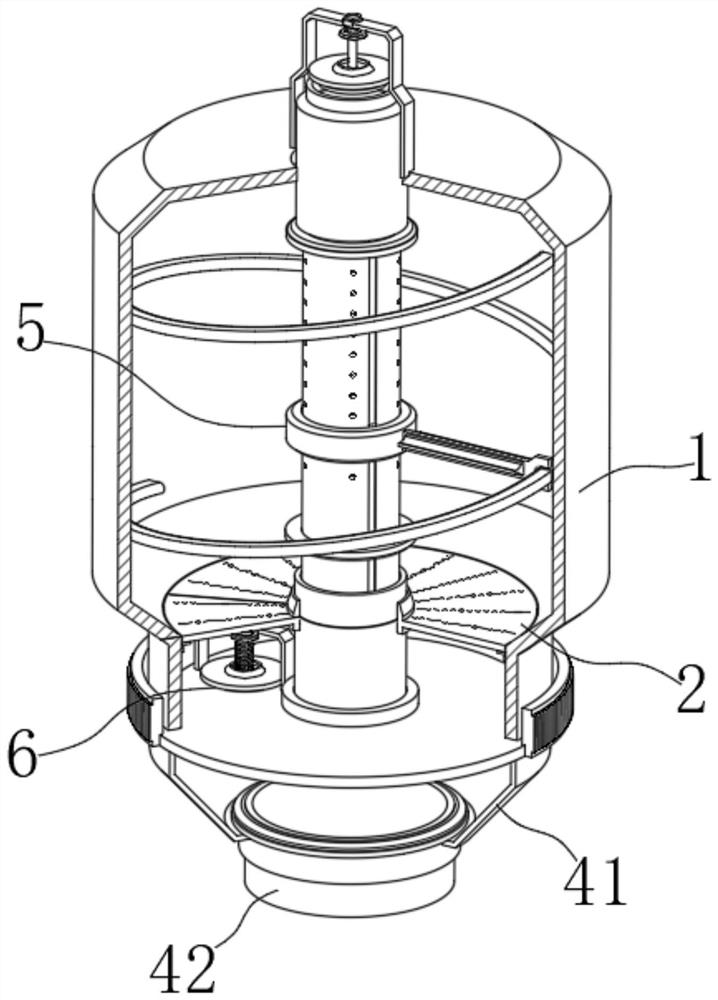

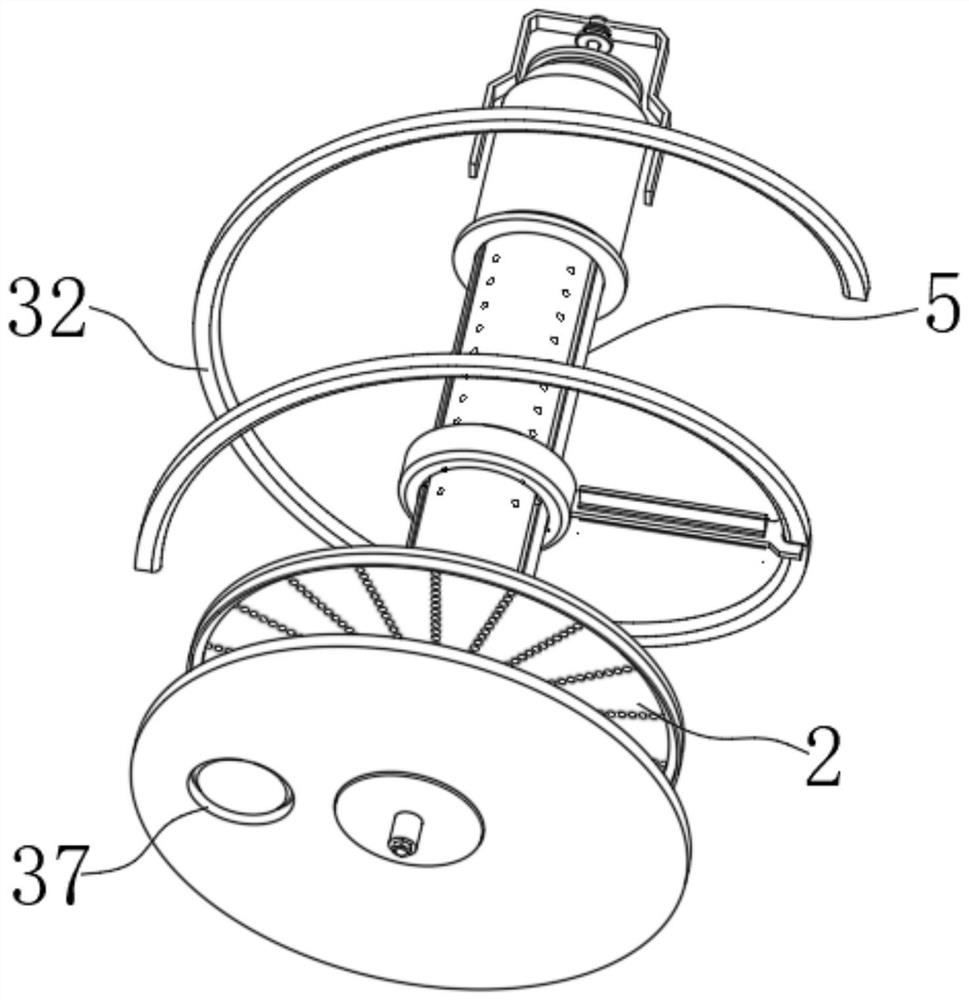

[0027] see figure 1 and figure 2 , a chemical raw material production waste gas treatment device in the illustration, including a treatment cylinder 1 for holding activated carbon, a filter plate 2 is fixed on the inner wall of the bottom of the treatment cylinder 1, and also includes a cover 3 and a stirring assembly 5, the cover 3 Covered on the bottom of the processing cylinder 1, and the bottom end of the cover 3 is connected with a connecting piece 4 that is docked with the exhaust gas pipeline. The stirring assembly 5 used to stir the activated carbon in the processing cylinder 1 to improve the adsorption effect is installed in the processing cylinder 1, and It is connected with the cover 3, and the detection mechanism 6 for detecting the saturation of activated carbon is installed on the top of the cover 3 and the stirring assembly 5.

[0028] It should be noted that: in this solution, an external gear ring is fixed on the outside of the cover 3, so that the belt pull...

Embodiment 2

[0040] see Figure 6 and Figure 7 , this embodiment is further described for Example 1. The limiting member 10 in the figure includes two connecting frames 24, and the two connecting frames 24 are respectively fixed on both sides of the bottom end of the rotating sleeve 8, and the two connecting frames 24 slide There are snap-in rods 25 plugged in, and two spacer slots 26 are arranged on the inner side of the connecting sleeve 7, and the outer ends of the snap-in rods 25 are fixed with snap-in balls 27 that are compatible with the spacer slots 26, and the outer ends of the snap-in rods 25 are covered with There is an extruding spring 28 against the stuck ball 27 and the connecting frame 24.

[0041] In this embodiment, the position of the rotating sleeve 8 can be controlled by designing the locking ball 27 in the limiting member 10 to move in different limiting grooves 26, so that the rotating sleeve 8 can rotate stably after each adjustment. The driving of the linkage mech...

Embodiment 3

[0044] see figure 1 and figure 2 , this embodiment is further described for other examples. A chemical raw material production waste gas treatment device in the illustration includes a treatment cylinder 1 for holding activated carbon. A filter plate 2 is fixed on the inner wall of the bottom of the treatment cylinder 1. The cover 3 and the stirring assembly 5, the cover 3 is set on the bottom of the treatment cylinder 1, and the bottom end of the cover 3 is connected with the connecting piece 4 connected with the waste gas pipeline, which is used to stir the activated carbon in the treatment cylinder 1 to improve the adsorption effect The component 5 is installed in the processing cylinder 1 and connected with the cover 3, and the detection mechanism 6 for detecting the saturation of activated carbon is installed on the top of the cover 3 and the stirring component 5 .

[0045] Also, see figure 2 , the connecting piece 4 in the figure includes a tapered sleeve 41 fixed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com