Online measurement equipment of viscosity of crude oil and measurement method

A technology of measuring equipment and measuring method, which is applied in the field of petrochemical industry, can solve the problems of high stability requirements of fluid and surrounding measurement environment, relatively strict requirements of measurement conditions, and great influence of environmental vibration, etc., and the online measurement method is simple and easy to implement , low stability requirements, and low environmental vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

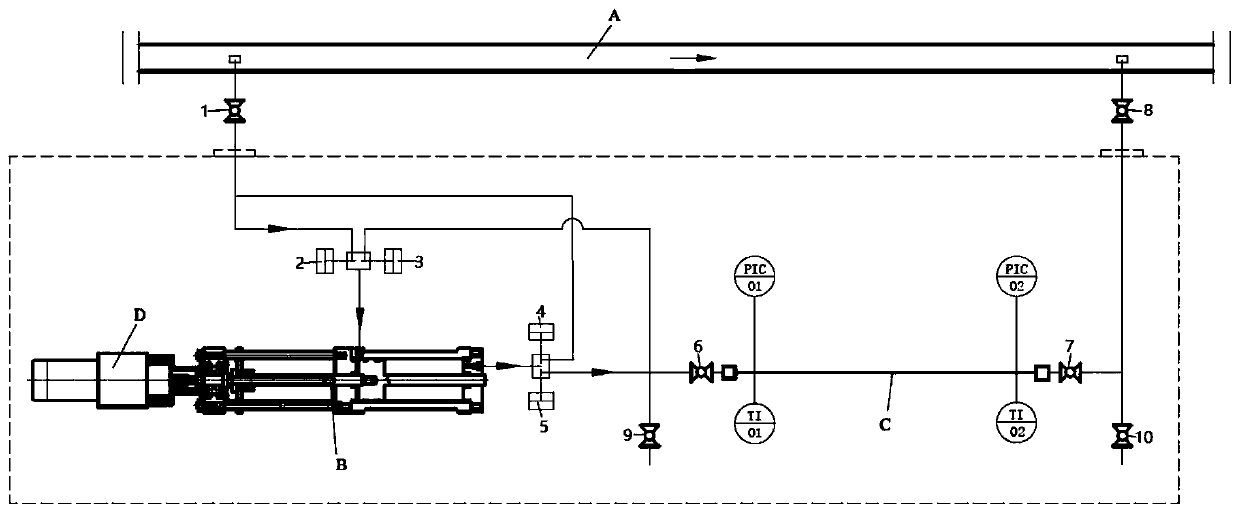

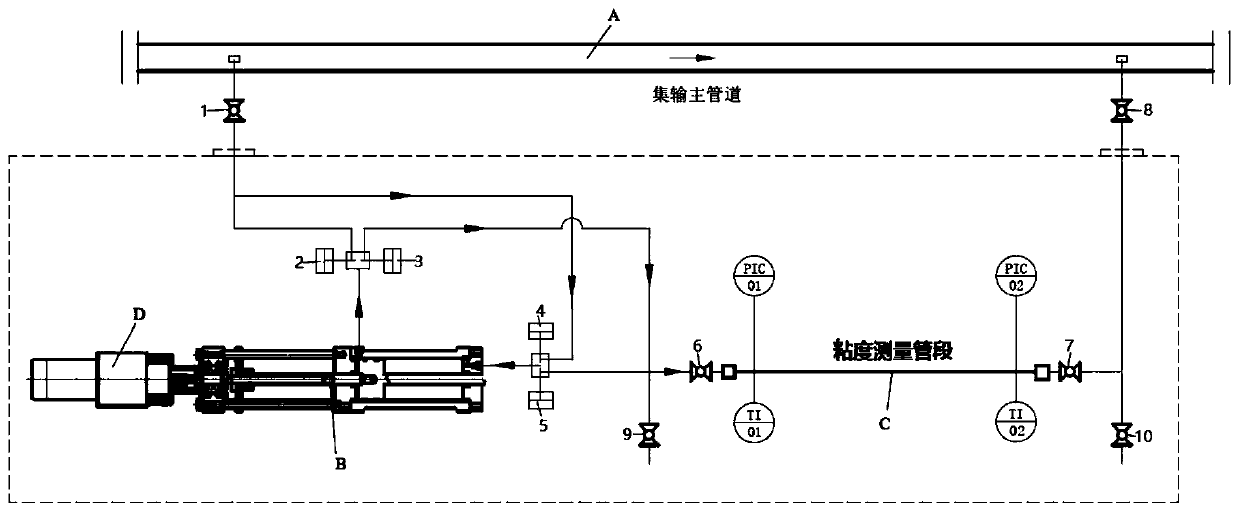

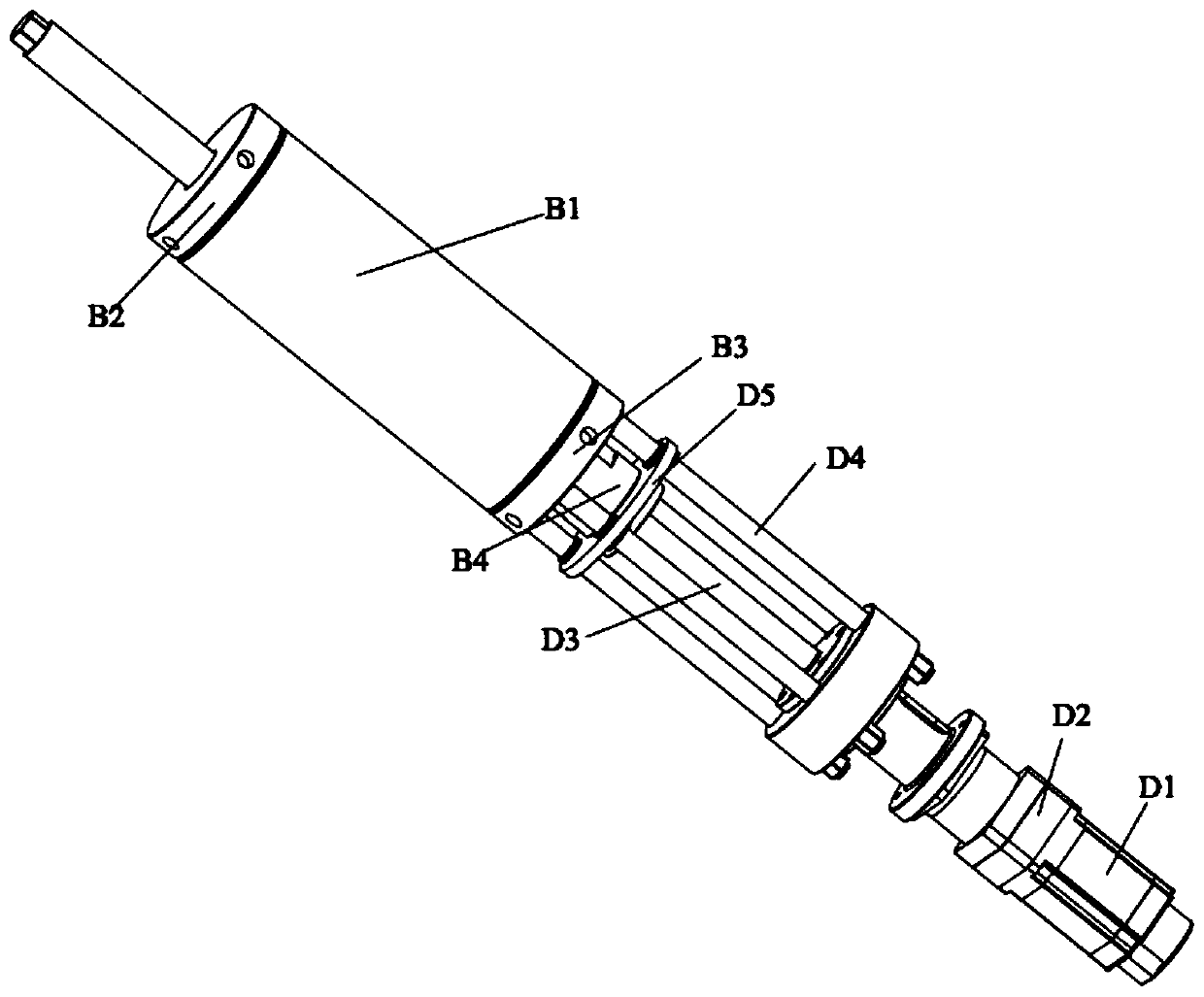

[0066] In the first embodiment of the present invention, an on-line measurement device for crude oil viscosity is provided, including: an oil suction circuit, a metering device B and a viscosity detection device C, wherein the oil suction circuit is connected in parallel with the main oil pipeline A; the metering device B It is connected (in series) with the oil suction oil circuit; the viscosity detection device C is connected (in series) with the metering device B through the oil suction oil circuit. in particular:

[0067]

[0068] The oil suction oil circuit of the present invention is arranged in parallel with the main oil circuit pipeline A, and is used for extracting crude oil samples from the main oil circuit pipeline A. In the present invention, the oil suction circuit may include a first oil circuit and a second oil circuit, wherein,

[0069] The first inlet pipe of the first oil circuit is connected in series with the first oil port of the metering device B; the ...

no. 2 approach

[0097] The second embodiment of the present invention provides an on-line measurement method for detecting the viscosity of crude oil by using the on-line measuring device for crude oil viscosity in the first embodiment, comprising the following steps: extracting a crude oil sample from the main oil pipeline A by using the oil suction circuit ; Use the metering device B to control the flow of the crude oil sample; use the viscosity detection device C to measure the viscosity of the crude oil sample. in particular:

[0098] The oil absorption oil circuit of the present invention includes a first oil circuit and a second oil circuit, wherein, when the crude oil sample passes through the first oil circuit, the crude oil sample passes through the first inlet pipe of the first oil circuit through the first inlet pipe of the metering device B. The oil port is transported to the metering device B, and flows out from the second oil port of the metering device B, and is transported to ...

Embodiment 1-6

[0135] First, the first valve 1 is opened, and the crude oil in the sand enters the oil suction circuit from the main oil pipeline A; the power device D is started, and during the upward movement of the piston (plunger) in the metering device B, the second valve 2 and the fifth The valve 5 is opened, the third valve 3 and the fourth valve 4 are closed, and the crude oil sample in the sand is pressed by the metering device B. figure 1 The first oil passage shown enters the viscosity detection device C with a constant flow rate. When the piston (plunger) in the metering device B goes up to the limit, it switches to the downward process, the third valve 3 and the fourth valve 4 are opened, the second valve 2 and the fifth valve 5 are closed, and the metering device B is used to make the sand Crude oil samples can still be pressed at a constant flow figure 2 The second oil passage shown enters the viscosity detection device C.

[0136] Open the sixth valve 6 to make the crude ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com