Automatic anti-uplift energy foundation pit support structure and construction method

A foundation pit enclosure and energy technology, which is applied in infrastructure engineering, excavation, refrigeration and liquefaction, etc., can solve the problems of slow construction period, long excavation time, and different effects, so as to eliminate the influence of assembly gaps and solve the problem. High footprint and cost, the effect of reducing exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

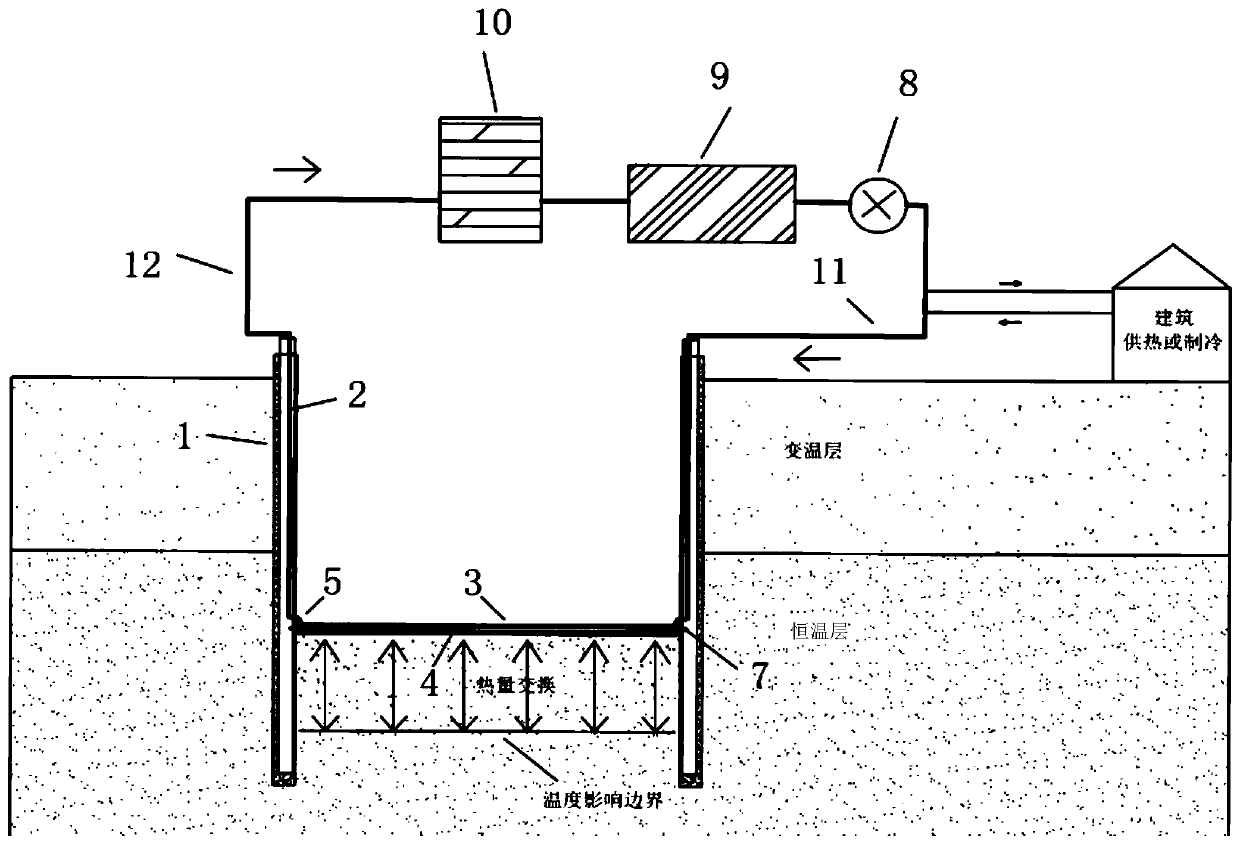

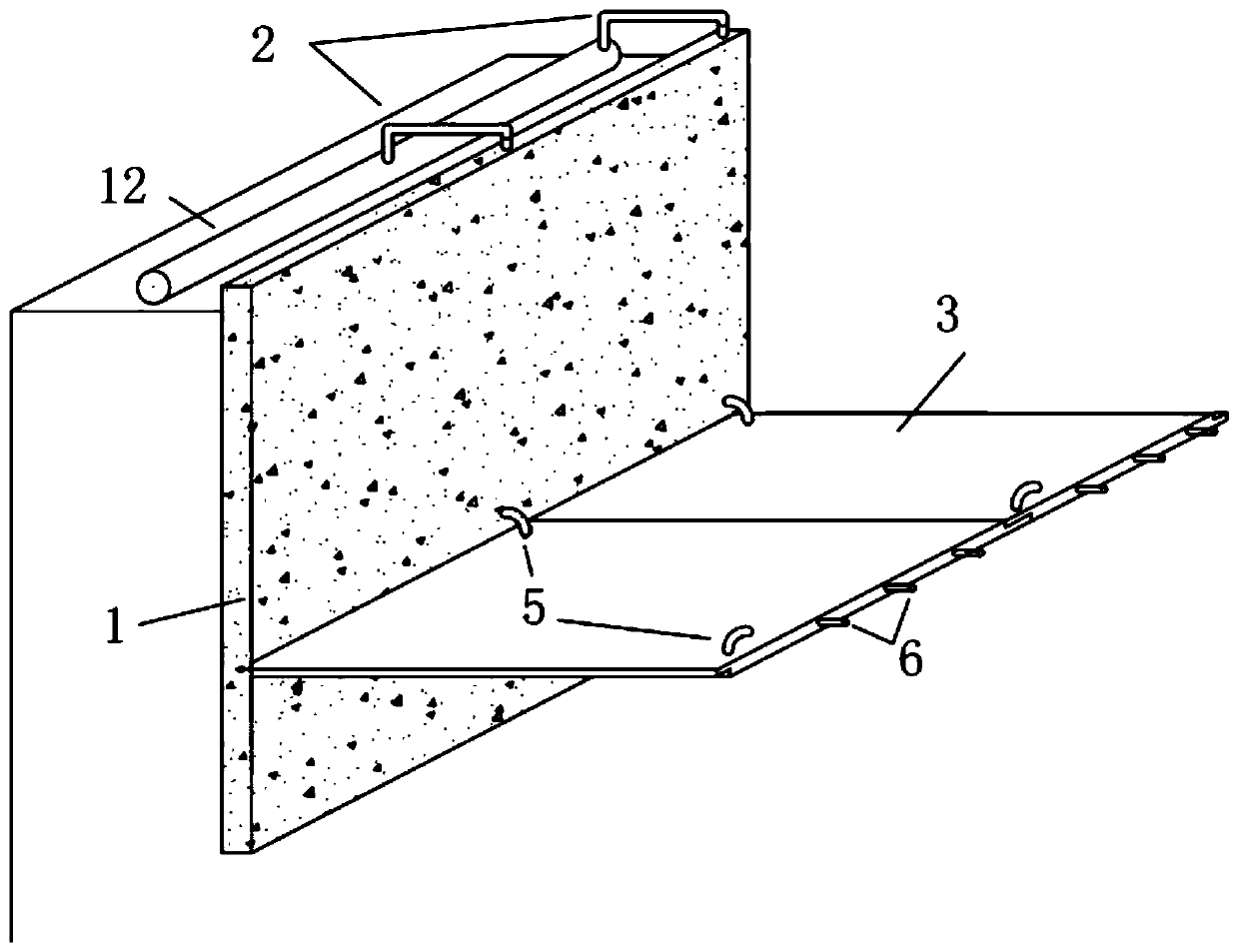

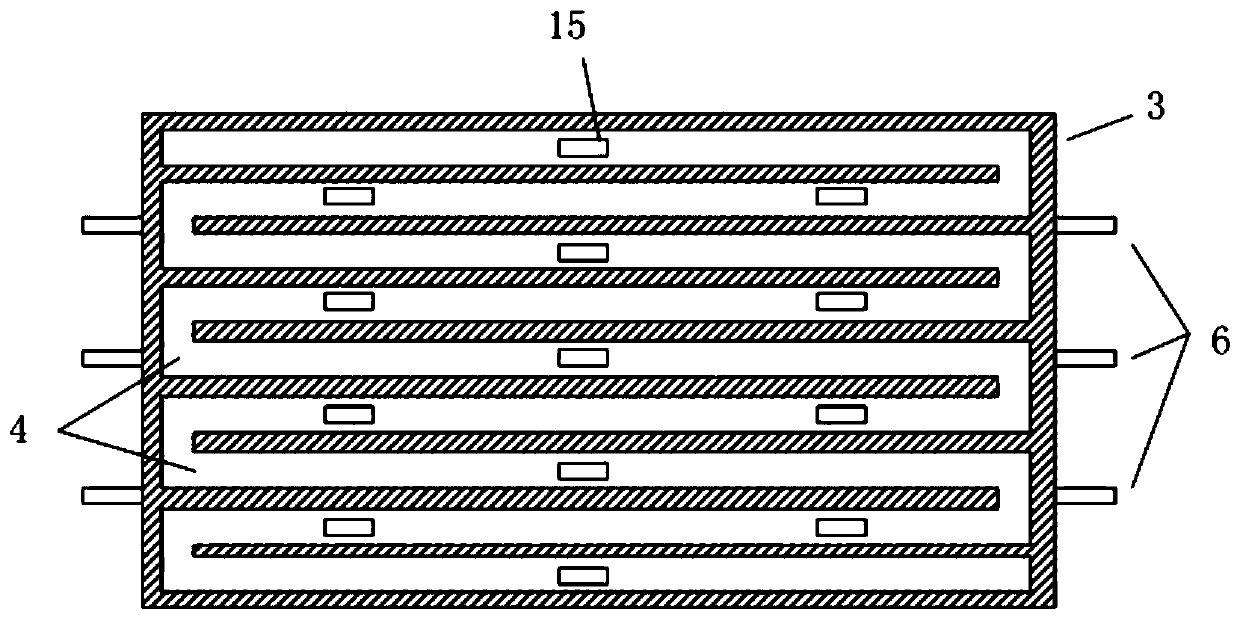

[0041] like figure 1 As shown, the foundation pit is supported by SMW piles as a whole, and the retaining wall of cement mixing piles is used for enclosure; I-beam is installed inside the retaining wall 1, and the inner side of the I-beam is the side of retaining wall 1 close to the foundation pit. 2. The bottom of the heat pipe 2 reaches the bottom of the foundation pit, and the top of the heat pipe 2 is a short distance above the top of the retaining wall 1, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com