A shallow fast pile driver suitable for soft ground

A pile driver and surface technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of limited impact speed, pile wear, slow speed, etc., to achieve the effect of increasing speed and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

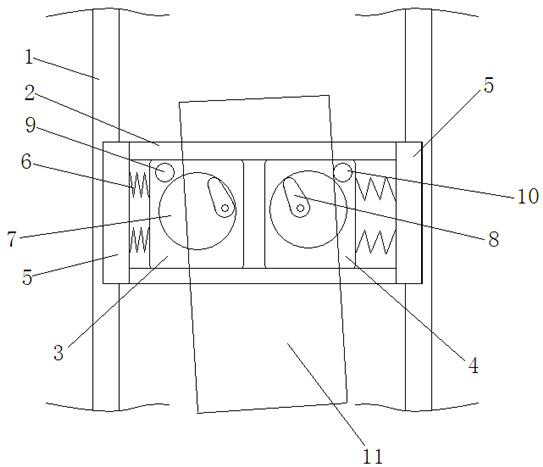

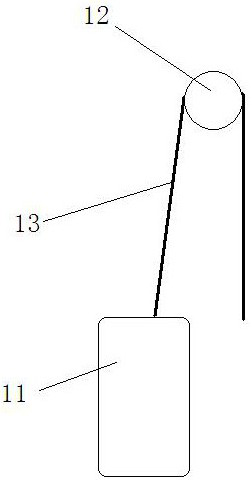

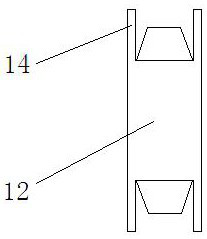

[0019] A shallow rapid pile driver suitable for soft ground according to the present invention comprises a pile frame 1, a pile hammer 11, a toggle mechanism and a lifting device;

[0020] The toggle mechanism is used to adjust the inclination of the pile hammer 11, and includes a pair of guide rail beams 2, a first slider 3 and a second slider 4 are arranged between the two guide rail beams 2, and the first slider 3 and the second slider The block 4 is limited to slide laterally between two guide rail beams 2, and the two ends of the guide rail beam 2 are respectively provided with side stoppers 5 fixed to the pile frame 1, that is, a pair of guide rail beams 2 and side stoppers 5 on both sides form a frame body, the first slider 3 and the second slider 4 are located in the frame body, the first slider 3 and the second slider 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com