Bamboo carbon fiber fly-knitted vamp

A bamboo charcoal fiber and flying weaving technology, which is applied in the field of bamboo charcoal fiber flying weaving shoe uppers, can solve the problems of discomfort, airtightness, unhealthy, etc., and achieve the effect of comfortable wearing, good air permeability and cool wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A bamboo charcoal fiber flying woven shoe upper is woven from bamboo charcoal fiber.

[0026] Wherein, the bamboo charcoal fiber is SORONA fiber.

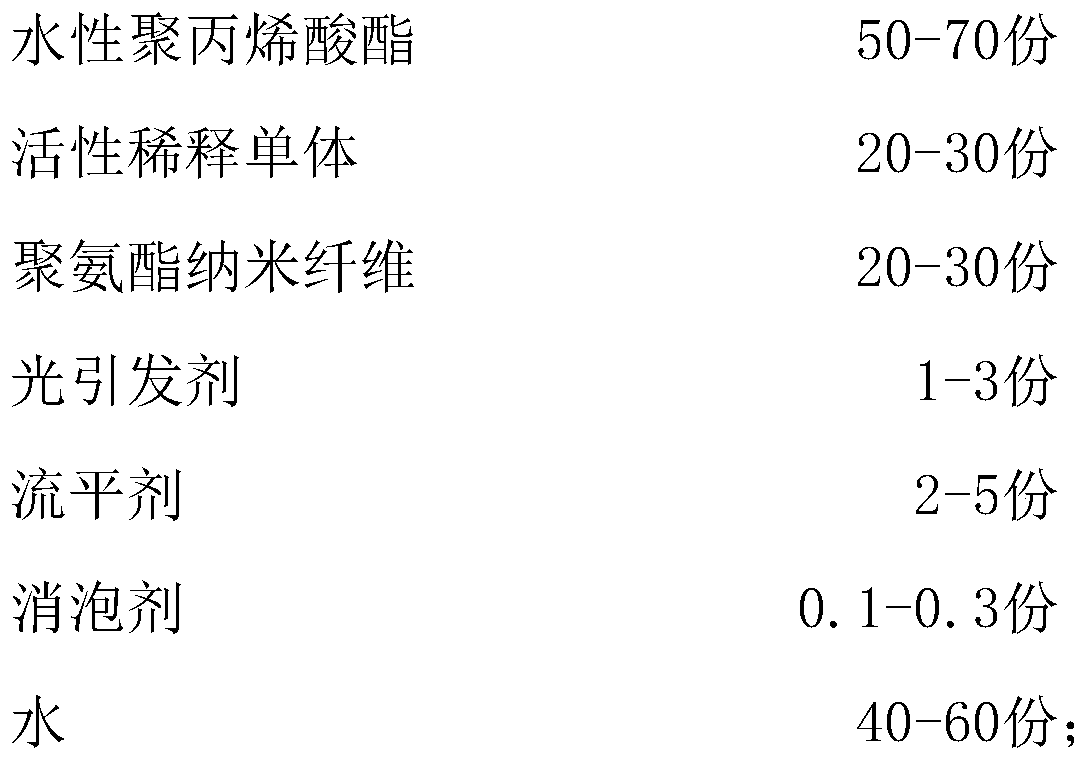

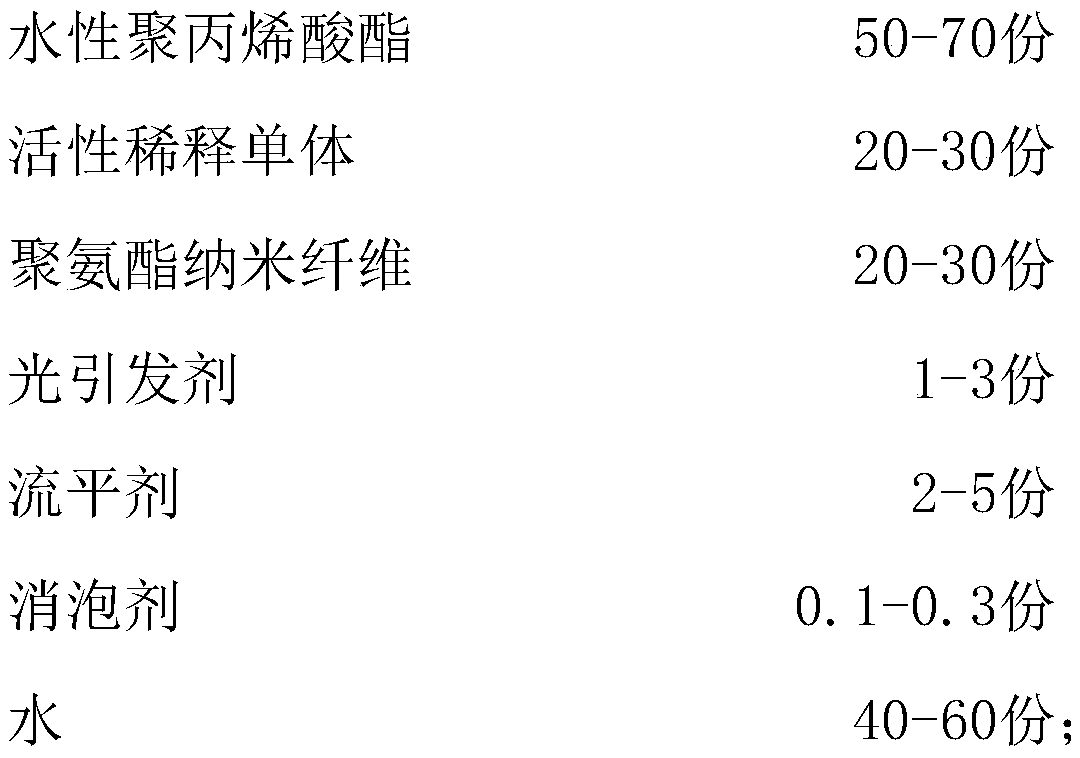

[0027] Wherein, the fly-woven shoe upper is coated with a waterproof and breathable coating, and the waterproof and breathable coating is coated with a water-based UV coating, and the water-based UV coating includes the following raw materials in parts by weight:

[0028]

[0029]

[0030] Wherein, the polyurethane nanofiber is prepared by the following method:

[0031] A. Mix 25 parts by weight of castor oil, 6 parts by weight of glycerin and 0.2 parts by weight of triethanolamine, heat up to 210° C. for alcoholysis reaction for 2.5 hours, cool to obtain alcoholylated castor oil;

[0032] B. Mix alcoholyzed castor oil, 55 parts by weight of isophorone diisocyanate and 100 parts by weight of N,N-dimethylacetamide, heat up to 60° C. and react for 2.5 hours to obtain a spinning solution;

[0033] C. Electrospinning the...

Embodiment 2

[0042] A bamboo charcoal fiber flying woven shoe upper is woven from bamboo charcoal fiber.

[0043] Wherein, the bamboo charcoal fiber is SORONA fiber.

[0044] Wherein, the flying woven shoe upper is coated with a waterproof and breathable coating, and the waterproof and breathable coating is coated with a water-based UV coating, and the water-based UV coating includes the following raw materials in parts by weight:

[0045]

[0046]

[0047] Wherein, the polyurethane nanofiber is prepared by the following method:

[0048] A. Mix 20 parts by weight of castor oil, 4 parts by weight of glycerin and 0.1 parts by weight of triethanolamine, heat up to 200° C. for alcoholysis reaction for 2 hours, and cool to obtain alcoholylated castor oil;

[0049] B. Mix alcoholyzed castor oil, 50 parts by weight of isophorone diisocyanate and 100 parts by weight of N,N-dimethylacetamide, heat up to 50° C. and react for 2 hours to obtain a spinning solution;

[0050] C. Electrospinning ...

Embodiment 3

[0059] A bamboo charcoal fiber flying woven shoe upper is woven from bamboo charcoal fiber.

[0060] Wherein, the bamboo charcoal fiber is SORONA fiber.

[0061] Wherein, the flying woven shoe upper is coated with a waterproof and breathable coating, and the waterproof and breathable coating is coated with a water-based UV coating, and the water-based UV coating includes the following raw materials in parts by weight:

[0062]

[0063] Wherein, the polyurethane nanofiber is prepared by the following method:

[0064] A. Mix 30 parts by weight of castor oil, 8 parts by weight of glycerin and 0.3 parts by weight of triethanolamine, heat up to 220° C. for alcoholysis reaction for 3 hours, and cool to obtain alcoholylated castor oil;

[0065] B. Mix alcoholyzed castor oil, 60 parts by weight of isophorone diisocyanate and 100 parts by weight of N,N-dimethylacetamide, heat up to 70° C. and react for 3 hours to obtain a spinning solution;

[0066] C. Electrospinning the spinning s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com