High elasticity anti-wrinkle textile fabric and preparation method thereof

A textile fabric and high-elasticity technology, applied in the field of textile fabrics, can solve problems such as inconsistency in elasticity and wrinkle resistance, poor elasticity of natural fibers, complex preparation process, etc., and achieve the effect of superior product quality, strong wrinkle resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

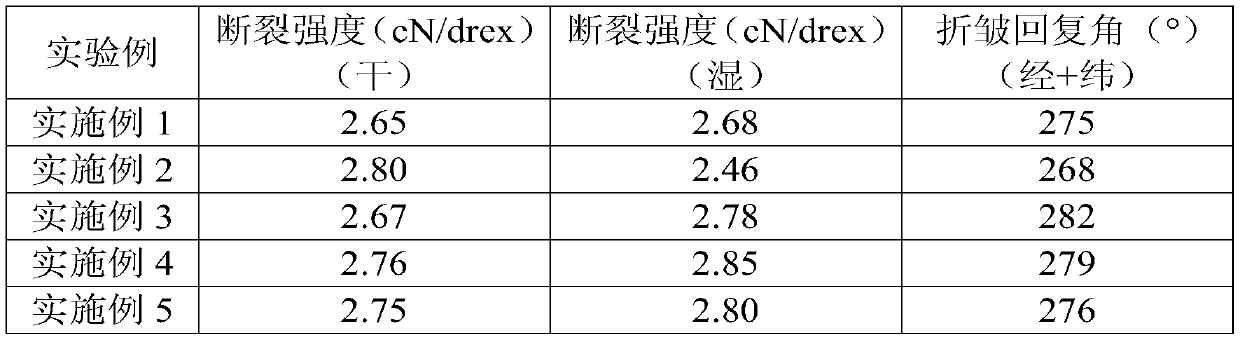

Examples

Embodiment 1

[0033] A kind of high elastic anti-wrinkle textile fabric

[0034] The high-elastic anti-wrinkle textile fabric is woven from warp and weft yarns. The combination of nettle fiber and long-staple cotton with a mass ratio of 3:3 is used as the warp yarn, and the combination of nettle fiber and long-staple cotton with a mass ratio of 1:3 is used as the weft yarn. The warp also includes polyester spandex, the mass ratio of polyester spandex to nettle fiber and long-staple cotton is 0.2:6; the length of nettle fiber is 35mm; the fineness of long-staple cotton is 7000m / g.

[0035] Include the following steps:

[0036] S10, after the nettle fiber is infiltrated with ethanol, it is placed in a modified solution, ultrasonicated for 1 hour at a temperature of 35° C., and after the filtrate is discarded, the nettle fiber is dried in the air at a wind speed of 1.0 m / s 2h, and then at a temperature of 95°C, dry for 30min to obtain the modified nettle fiber for subsequent use;

[0037]In ...

Embodiment 2

[0045] A kind of high elastic anti-wrinkle textile fabric

[0046] The high-elastic wrinkle-resistant textile fabric is woven from warp and weft yarns. The combination of nettle fiber and long-staple cotton with a mass ratio of 5:3 is used as the warp yarn, and the combination of nettle fiber and long-staple cotton with a mass ratio of 2:3 is used as the weft yarn. The warp also includes polyester spandex, the mass ratio of polyester spandex to nettle fiber and long-staple cotton is 0.5:6; the length of nettle fiber is 45mm; the fineness of long-staple cotton is 7500m / g.

[0047] Include the following steps:

[0048] S10, after the nettle fiber is infiltrated with ethanol, it is placed in a modified solution, ultrasonicated for 2 hours at a temperature of 45°C, and after the filtrate is discarded, the nettle fiber is dried in the air at a wind speed of 1.6m / s 3h, and then at a temperature of 125°C, dry for 60min to obtain the modified nettle fiber for subsequent use;

[0049...

Embodiment 3

[0057] A kind of high elastic anti-wrinkle textile fabric

[0058] The high-elastic anti-wrinkle textile fabric is woven from warp and weft yarns. The combination of nettle fiber and long-staple cotton with a mass ratio of 3.5:3 is used as the warp yarn, and the combination of nettle fiber and long-staple cotton with a mass ratio of 1.2:3 is used as the weft yarn. The warp also includes polyester spandex, the mass ratio of polyester spandex to nettle fiber and long-staple cotton is 0.3:6; the length of nettle fiber is 37mm; the fineness of long-staple cotton is 7200m / g.

[0059] Include the following steps:

[0060] S10, after the nettle fiber is infiltrated with ethanol, it is placed in a modified solution, ultrasonicated for 1.2 hours at a temperature of 38° C., and after the filtrate is discarded, the nettle fiber is air-dried at a wind speed of 1.2 m / s. Dry for 2.2 hours, and then dry for 40 minutes at a temperature of 98°C to obtain modified nettle fibers for subsequent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com