Bark crepe fabric and weaving process thereof

A fabric and bark technology, applied in the field of bark wrinkle fabric and its weaving process, can solve the problems affecting the development of textile technology, high consumption of weaving equipment, insufficient softness of fabrics, etc., and achieve excellent drape and low consumption of special textile equipment , soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

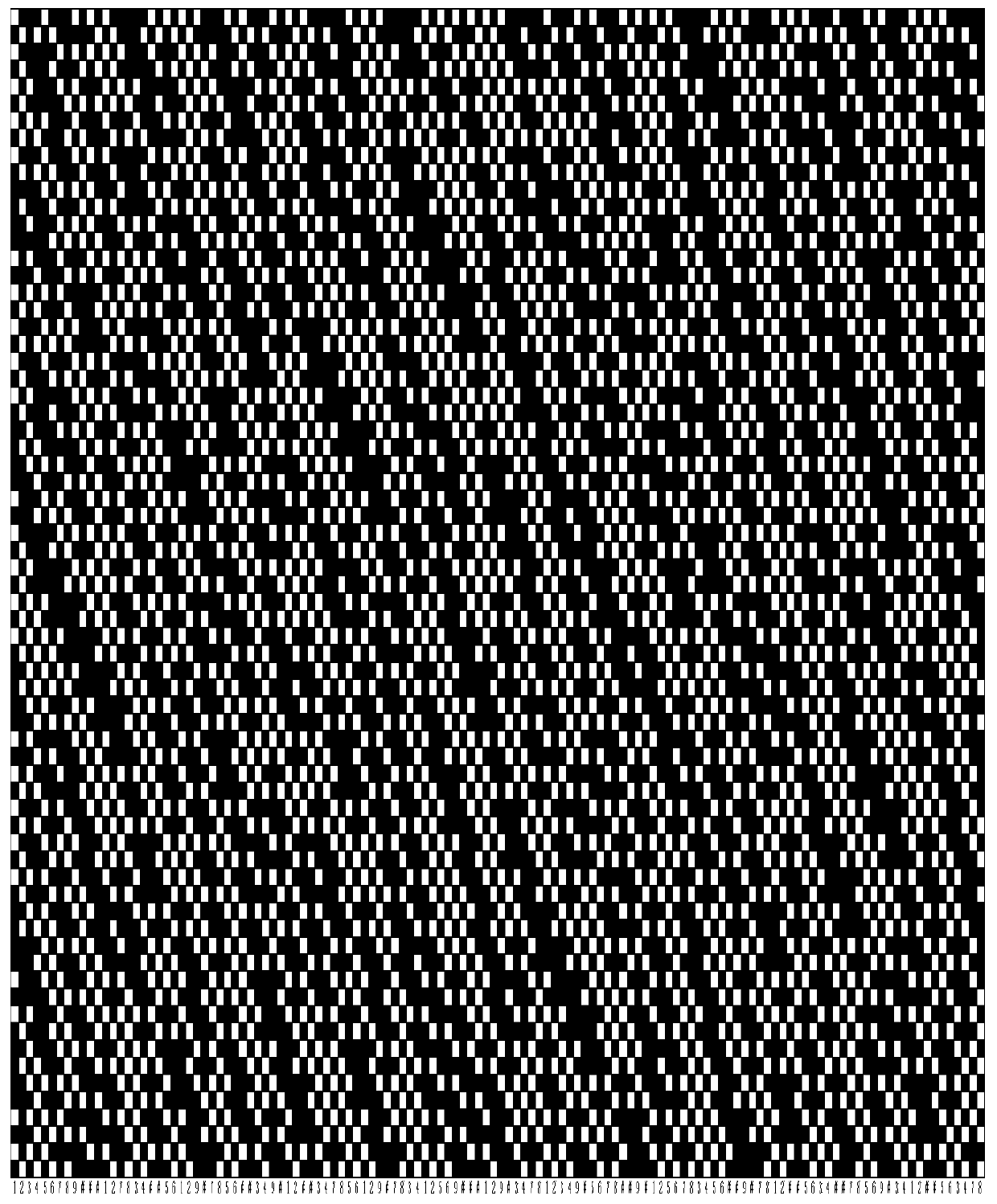

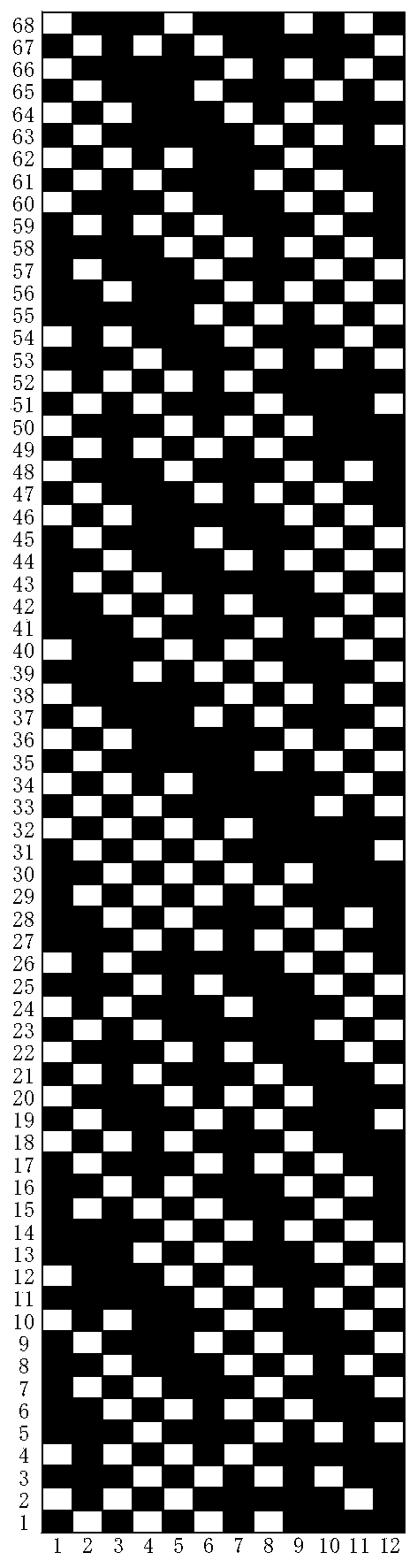

Image

Examples

Embodiment 1

[0032] The weaving process of the above-mentioned bark wrinkle fabric is as follows in sequence:

[0033] (1) Winding process: use a fully automatic winder to wind the bobbin into a large-capacity, well-formed bobbin, and then remove the defects and impurities on the yarn;

[0034] (2) warping process: adopt warping machine to draw warp yarn from winding bobbin, form a piece of yarn, make warp yarn have uniform tension force, maintain the speed of a vehicle in this process to be 430m / min;

[0035] (3) Sizing process: use a sizing machine with single immersion and double pressure sizing. The specific working parameters are: sizing pressure force 1.3~1.7×10KN, steam pressure 0.33~0.45MPa, sizing tank temperature 83℃~92℃, The temperature of the main cylinder is 51℃~92℃, the viscosity of the slurry is 60 mph, and the maximum speed is 38m / min;

[0036] (4) Reeding process: The warp yarns are passed through the warp droppers, heddles and reeds sequentially according to the method s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com