Drilling fluid and nanometer blocking agent for drilling fluid of oil field

A nano-blocking agent and oilfield drilling technology, which is applied in the field of oilfield drilling fluid, can solve the problems of effective plugging of nano-scale micro-fractures, ineffective plugging and anti-slumping, poor plugging effect, etc., achieving remarkable plugging effect, Improve mud cake ability and stabilize well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

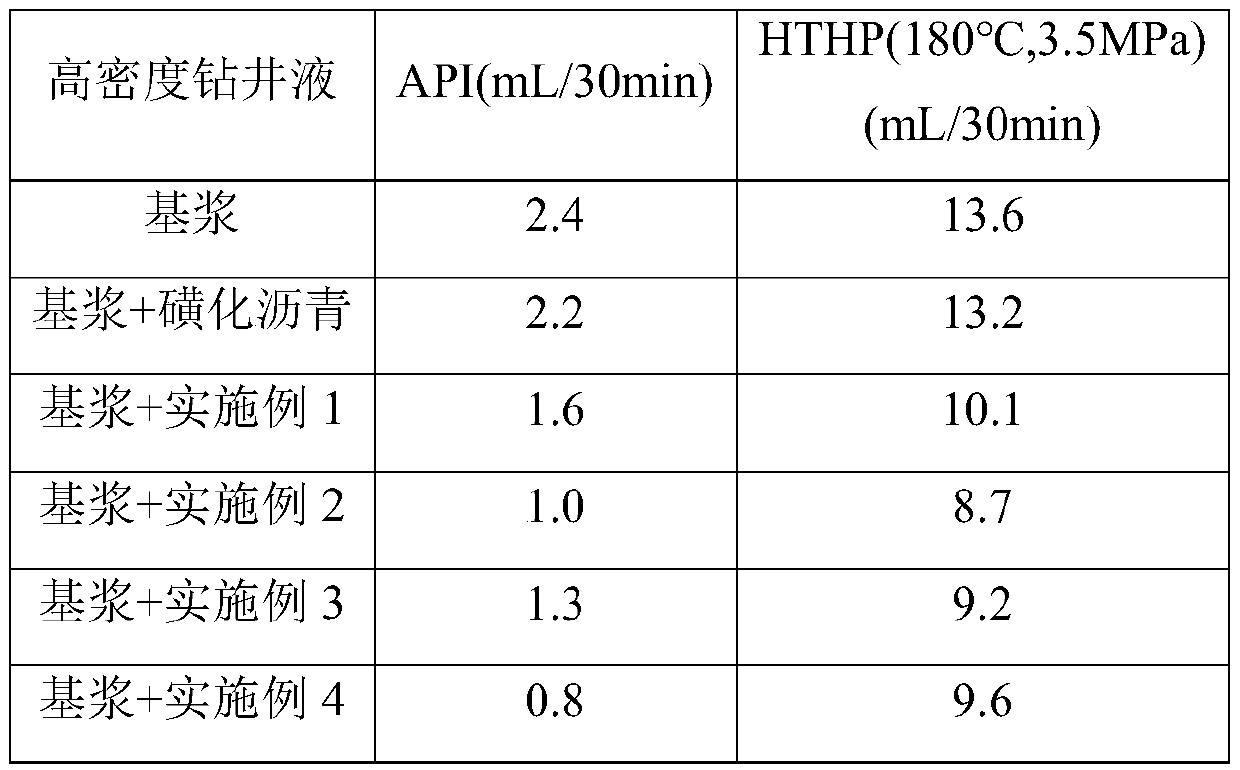

Examples

Embodiment 1

[0020] According to the weight ratio, 38 parts of industrial superior grade acetylacetone were added to the reactor, and 22 parts of industrial superior grade methyl isobutyl ketone and 42 parts of industrial superior grade 4-hydroxy-4-methyl-2- Pentanone, 1.6 parts of industrial superior grade cyclohexanone, stirred at room temperature for 20 minutes until uniform, then added 1.5 parts of industrial superior grade diethanolamine to catalyze and participate in the reaction, heated slowly, raised the temperature to 105°C, and kept 105°C at The reaction was continued for 6 hours under stirring, and cooled to obtain the nano plugging agent for oilfield drilling fluid of this embodiment.

Embodiment 2

[0022] According to the weight ratio, 42 parts of industrial superior grade acetylacetone were added to the reactor, and 28 parts of industrial superior grade methyl isobutyl ketone and 46 parts of industrial superior grade 4-hydroxy-4-methyl-2- Pentanone, 1.9 parts of industrial superior grade cyclohexanone, stirred at room temperature for 20 minutes until uniform, then added 1.6 parts of industrial superior grade diethanolamine to catalyze and participate in the reaction, heated slowly, raised the temperature to 105°C, and kept 105°C at The reaction was continued for 6 hours under stirring, and cooled to obtain the nano plugging agent for oilfield drilling fluid of this embodiment.

Embodiment 3

[0024] According to the weight ratio, 45 parts of industrial superior grade acetylacetone were added to the reactor, and 26 parts of industrial superior grade methyl isobutyl ketone and 48 parts of industrial superior grade 4-hydroxy-4-methyl-2- Pentanone, 1.9 parts of industrial superior grade cyclohexanone, stirred at room temperature for 20 minutes until uniform, then added 1.7 parts of industrial superior grade diethanolamine to catalyze and participate in the reaction, heated slowly, raised the temperature to 105°C, and kept 105°C at The reaction was continued for 6 hours under stirring, and cooled to obtain the nano plugging agent for oilfield drilling fluid of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com