Chromatographic separation method for maltitol

A maltitol and chromatographic separation technology, applied in the field of chromatographic separation of maltitol, can solve the problems of high operating cost, complicated process, and small product particle size, and achieve the effects of high product quality, guaranteed yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

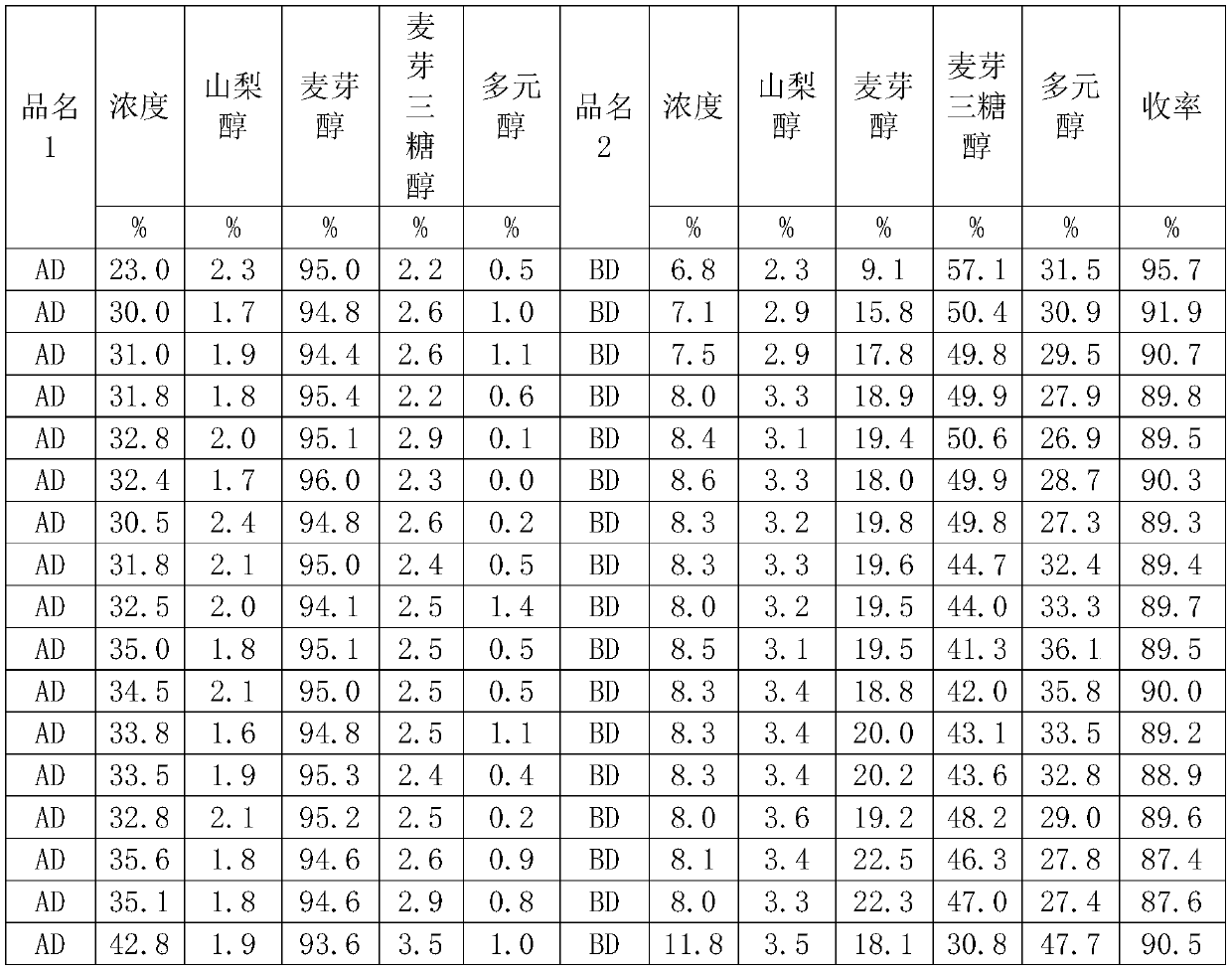

[0048] In order to verify the feasibility and economy of the method for chromatographic separation of maltitol of the present invention in the separation of maltitol, a small industrial chromatographic separation test was carried out in cooperation with Shandong Bailong Chuangyuan.

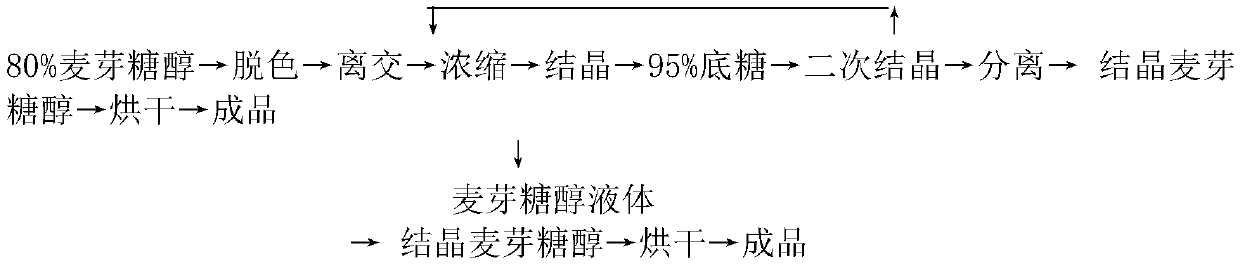

[0049] A method for chromatographically separating maltitol of the present invention, the liquid material to be separated is separated through a chromatographic separation system, so that the concentration of the maltitol component after separation is increased to 95%, and then directly concentrated for one crystallization to obtain crystalline maltitol product.

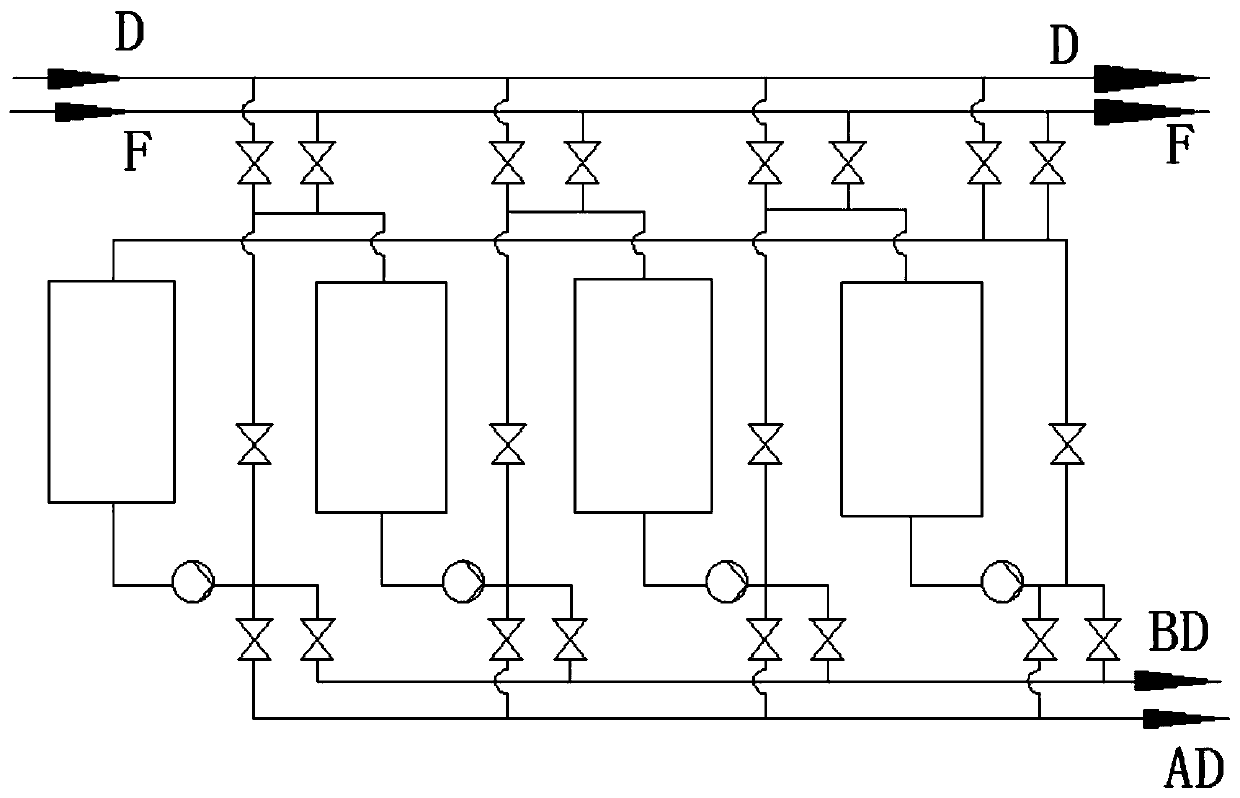

[0050] In the chromatographic separation system, the circular back pressure feeding system is adopted to realize smooth continuous feeding. The following is the discharging system, and the feeding and discharging are all switched by program control through pneumatic switch valves.

[0051] The process is simple and adopts automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com