A cooling device for explosive production

A cooling device and explosive technology, which is applied to explosives, explosives processing equipment, offensive equipment, etc., to achieve the effect of reducing equipment temperature, ensuring safety, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

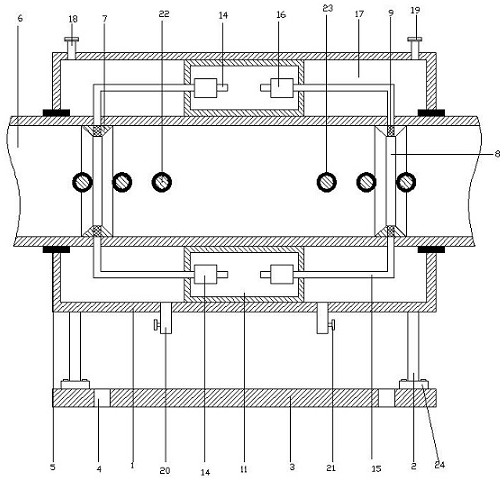

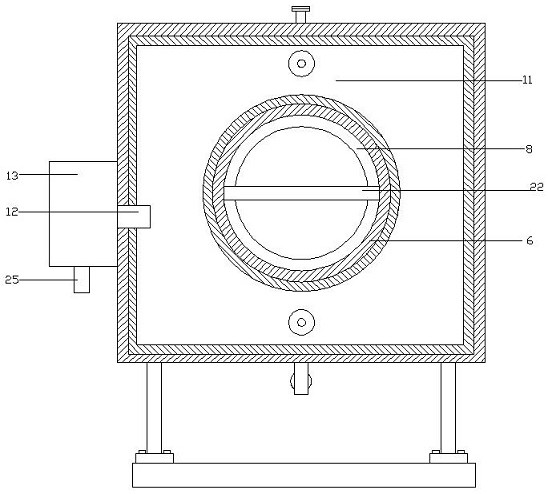

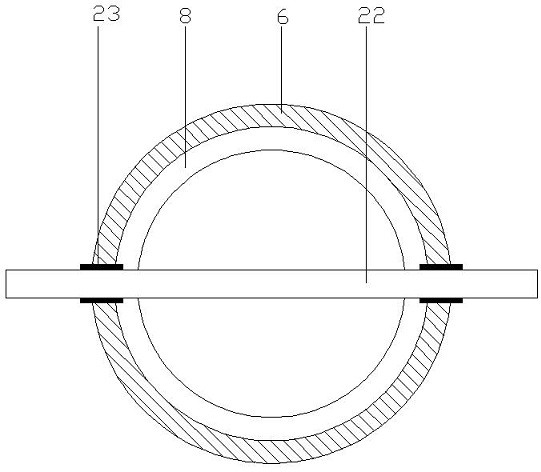

[0021] refer to Figure 1~3 , in an embodiment of the present invention, a cooling device for explosive production includes a connection cover 1, the left and right ends of the connection cover 1 are connected to the cooling pipe 6 through the first sealing ring 5, which can ensure that the cooling pipe 6 is sealed with the first The sealing of the ring 5, the middle part of the inner side of the connecting cover 1 is provided with a condensation chamber 11, the condensation chamber 11 is arranged on the outside of the cooling pipe 6, and a condenser 13 is installed on the connecting cover 1 at the rear side of the condensation chamber 11, which can condense the air , the lower side of the condenser 13 is provided with an air inlet pipe 25, and the condenser 13 is connected with the condensation chamber 11 through the cold air pipe 12, which can conveniently supply air to the condensation chamber 11, and the left and right ends of the inside of the cooling pipe 6 are respective...

Embodiment 2

[0024] The difference from the first embodiment is that the four corners of the lower side of the connecting cover 1 are fixedly welded with the supporting legs 2, the lower side of the supporting legs 2 is welded with the mounting block 24, and the lower side of the mounting block 24 is connected with the bottom plate 3 by bolts, which can facilitate the connection between equipment and The bottom plates 3 are installed with each other, and the four corners of the bottom plates 3 are provided with installation holes 4, which can facilitate the installation and fixing of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com