Preparation method of liquid cement grinding aid

A cement grinding aid and liquid technology, which is applied in the field of preparation of liquid cement grinding aids, can solve the problems of not improving the performance of antistatic, penetration and diffusion, etc., to improve cement quality, reduce production costs, and increase grinding aid efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

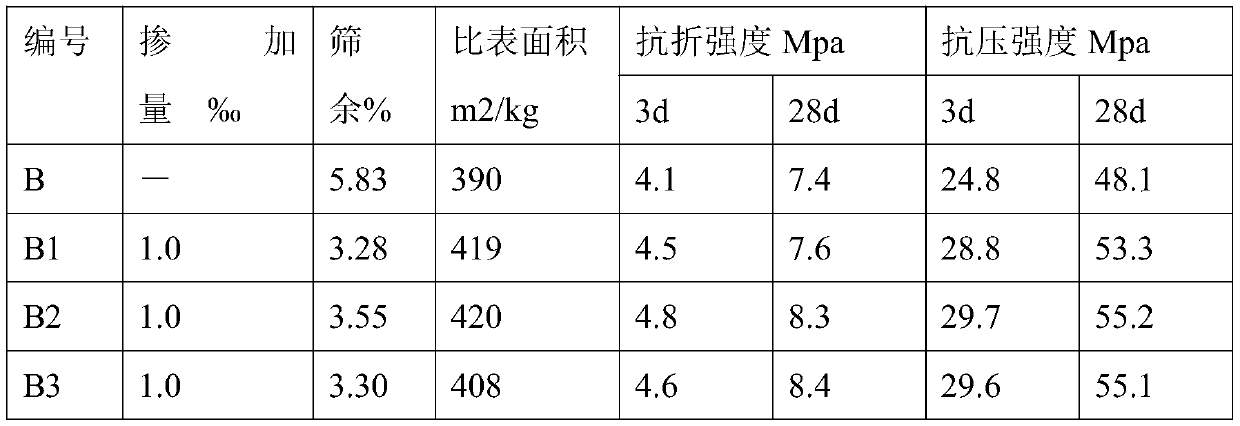

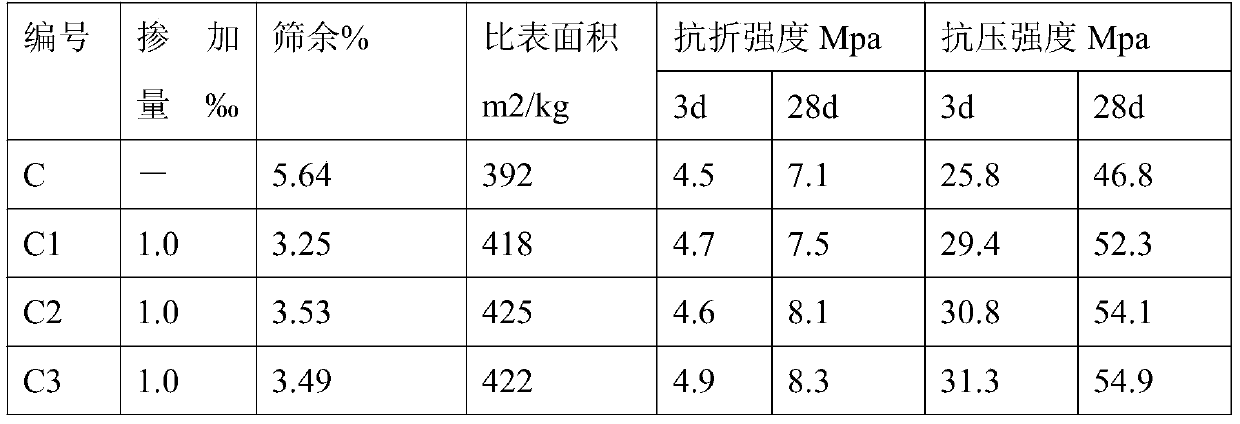

Examples

Embodiment 1

[0023] A liquid cement grinding aid, characterized in that: it is made of the following raw materials: dodecyl dimethyl tertiary amine, didodecyl methylamine, isopropanol, methyl chloride, alkali, and an appropriate amount of deionized water .

[0024] Concrete, the preparation method of liquid cement grinding aid comprises the following steps:

[0025] (1) Feeding: Add isopropanol, deionized water, dodecyldimethyl tertiary amine, didodecylmethylamine successively in the reactor, then add catalyst base, and stir;

[0026] (2) Reaction: After replacing the air in the reactor, gradually increase the temperature, control the temperature at 80-85°C, feed in methyl chloride while stirring, and react for 6 hours under a pressure of 0.2MPA to obtain material W;

[0027] (3) Discharging: After the material W is cooled to normal pressure, add an appropriate amount of deionized water to dilute, discharge, and fill the finished product.

[0028] Material W is a mixture of dodecyl trime...

Embodiment 2

[0044] A liquid cement grinding aid, characterized in that: it is made of the following raw materials in weight ratio: mixed reactant, dodecyl dimethyl tertiary amine, didodecyl methylamine, isopropanol, methyl chloride , alkali, and appropriate amount of deionized water.

[0045] Concrete, the preparation method of liquid cement grinding aid comprises the following steps:

[0046] (1) Feeding: Add isopropanol, deionized water, dodecyldimethyl tertiary amine, didodecylmethylamine successively in the reactor, then add catalyst base, and stir;

[0047] (2) Reaction: After replacing the air in the reactor, gradually increase the temperature, control the temperature at 80-85°C, feed in methyl chloride while stirring, and react for 6 hours under a pressure of 0.3MPA to obtain material W;

[0048] (3) Discharging: After the material W is cooled to normal pressure, add an appropriate amount of deionized water to dilute, discharge, and fill the finished product.

[0049] The mixed r...

Embodiment 3

[0065] A liquid cement grinding aid, characterized in that: it is made of the following raw materials in weight ratio: mixed reactant, dodecyl dimethyl tertiary amine, didodecyl methylamine, isopropanol, methyl chloride , alkali, and appropriate amount of deionized water.

[0066] Concrete, the preparation method of liquid cement grinding aid comprises the following steps:

[0067] (1) Feeding: Add isopropanol, deionized water, dodecyldimethyl tertiary amine, didodecylmethylamine successively in the reactor, then add catalyst base, and stir;

[0068] (2) Reaction: After replacing the air in the reactor, gradually increase the temperature, control the temperature at 80-85°C, feed in methyl chloride while stirring, and react for 6 hours under a pressure of 0.2-0.3MPA to obtain material W;

[0069] (3) Discharging: After the material W is cooled to normal pressure, add an appropriate amount of deionized water to dilute, discharge, and fill the finished product.

[0070] The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com