Automatic drilling tool and working method thereof

A drilling tool and drilling tool technology, which is applied in boring/drilling, drilling/drilling equipment, positioning devices, etc., can solve the problems of low efficiency of drilling tooling, complicated procedures, high equipment and environmental requirements, and achieve High drilling efficiency, accurate drilling positioning, and improved drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

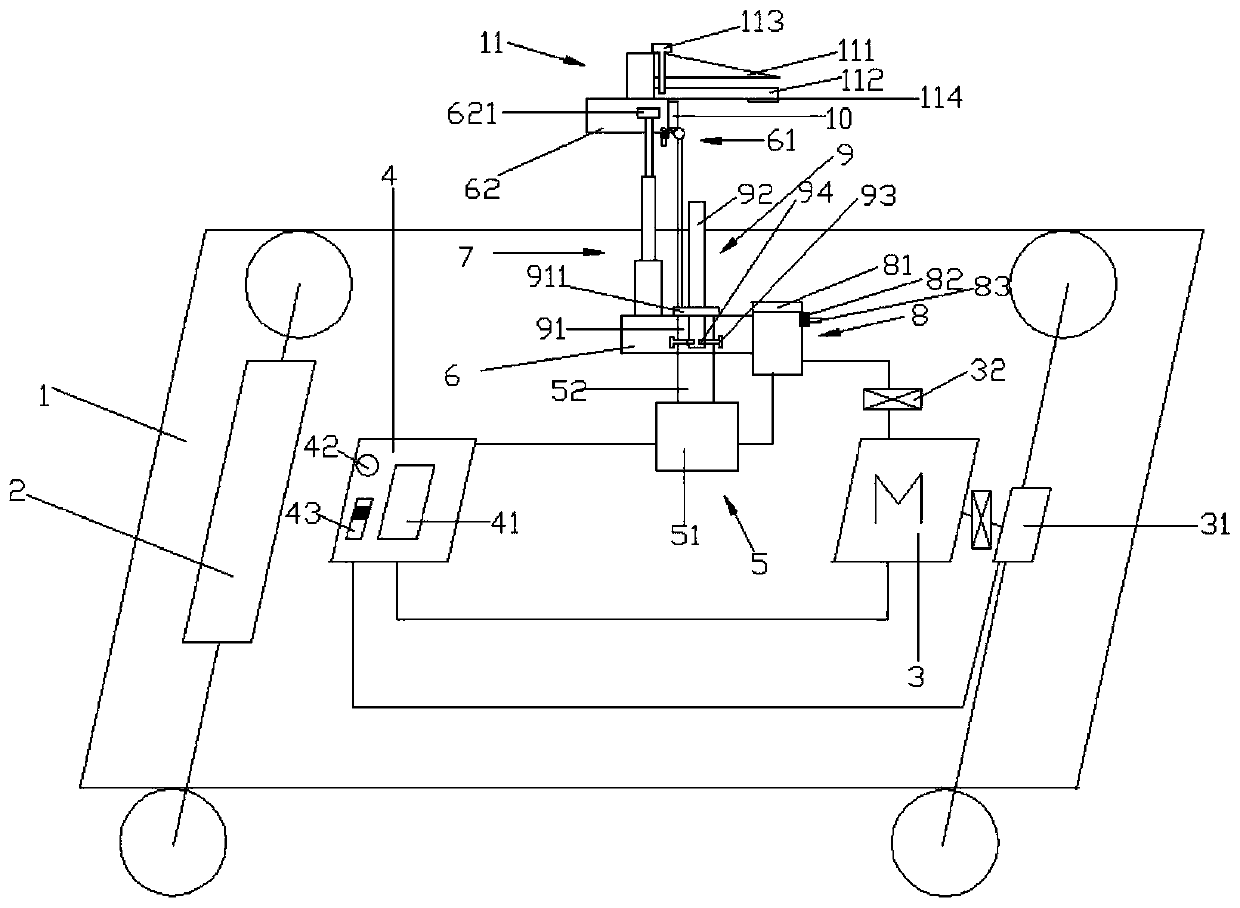

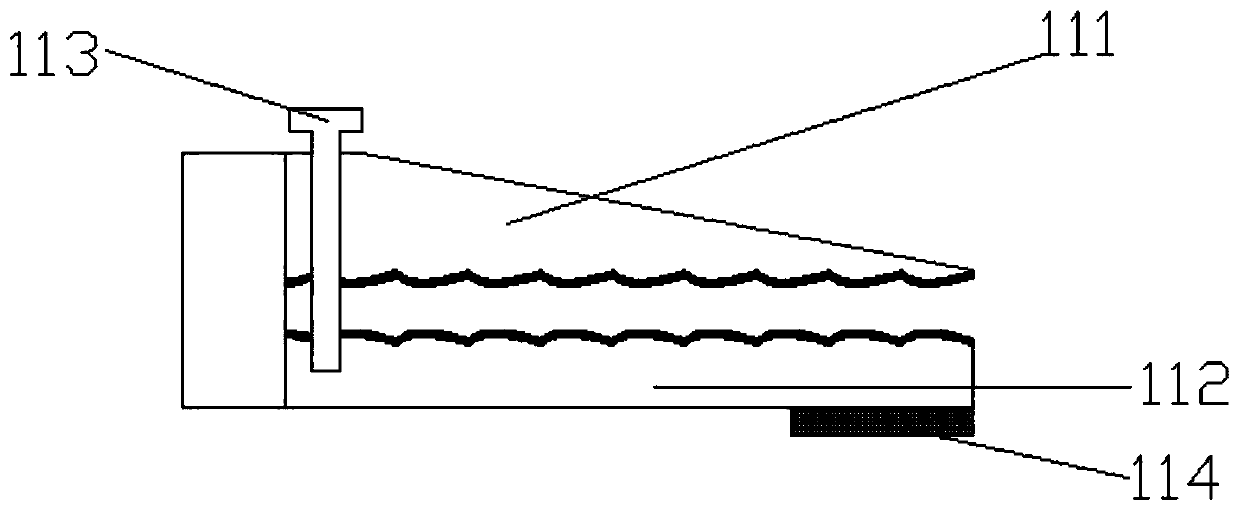

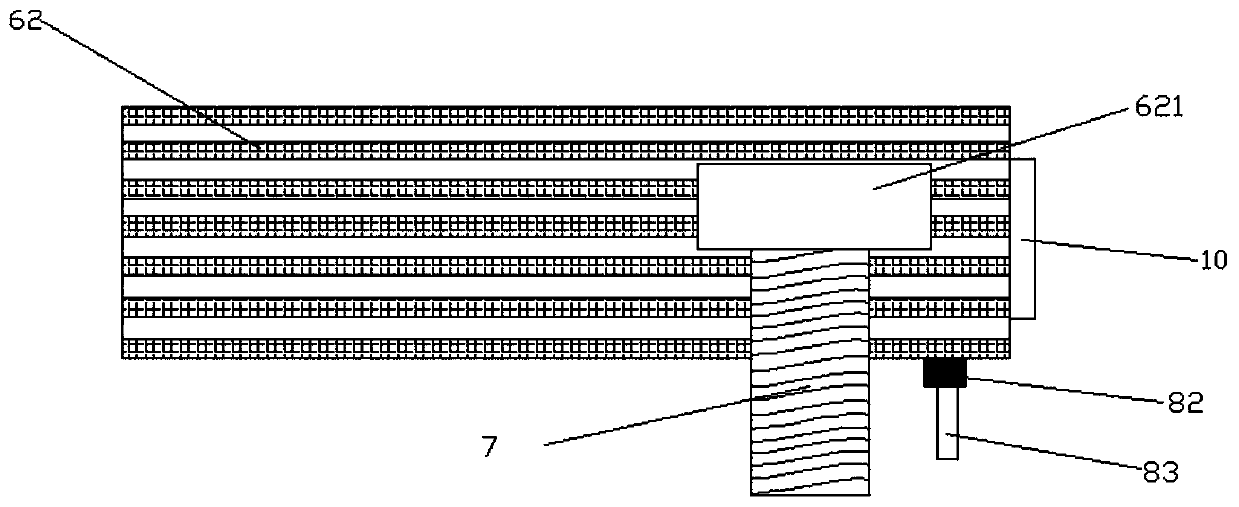

[0031] like figure 1 Shown: an automatic drilling tool and its working method, including a trolley 1, an automobile turning control system 2, an electric motor 3, an industrial computer 4, a hydraulic motor 5, a base 6, a telescopic rod 7, an optical power meter 8, a drilling tool 9. Reflector 10 and fixture 11; described automobile turning control system 2, industrial computer 4, electric motor 3, hydraulic motor 5, base 6 and telescopic rod 7 are all installed on the trolley 1, the optical power meter 8 and drill The tool 9 is installed on the base 6, the motor 3 is connected to the industrial computer 4, the hydraulic motor 5 and the optical power meter 8, and the drilling tool 9 and the hydraulic motor 5 are fixedly connected, and the telescopic rod 7 and the fixture 11 are provided with The handle 62 is fixed, and the mirror 10 is installed on the side of the fixed handle 62 , the connection part between the fixed handle 62 and the telescopic rod 7 is provided with an oil...

Embodiment 2

[0041] like figure 1 Shown: an automatic drilling tool and its working method, including a trolley 1, an automobile turning control system 2, an electric motor 3, an industrial computer 4, a hydraulic motor 5, a base 6, a telescopic rod 7, an optical power meter 8, a drilling tool 9. Reflector 10 and fixture 11; described automobile turning control system 2, industrial computer 4, electric motor 3, hydraulic motor 5, base 6 and telescopic rod 7 are all installed on the trolley 1, the optical power meter 8 and drill The tool 9 is installed on the base 6, the motor 3 is connected to the industrial computer 4, the hydraulic motor 5 and the optical power meter 8, and the drilling tool 9 and the hydraulic motor 5 are fixedly connected, and the telescopic rod 7 and the fixture 11 are provided with The handle 62 is fixed, and the mirror 10 is installed on the side of the fixed handle 62 , the connection part between the fixed handle 62 and the telescopic rod 7 is provided with an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com