An automatic clamping device for high-voltage grounding wire

An automatic clamping and grounding wire technology, which is applied in the direction of clamping/spring connection, multi-core cable end parts, etc., can solve the problems of wire falling off and inconvenient operation, and achieve the reduction of personnel burden, labor intensity and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

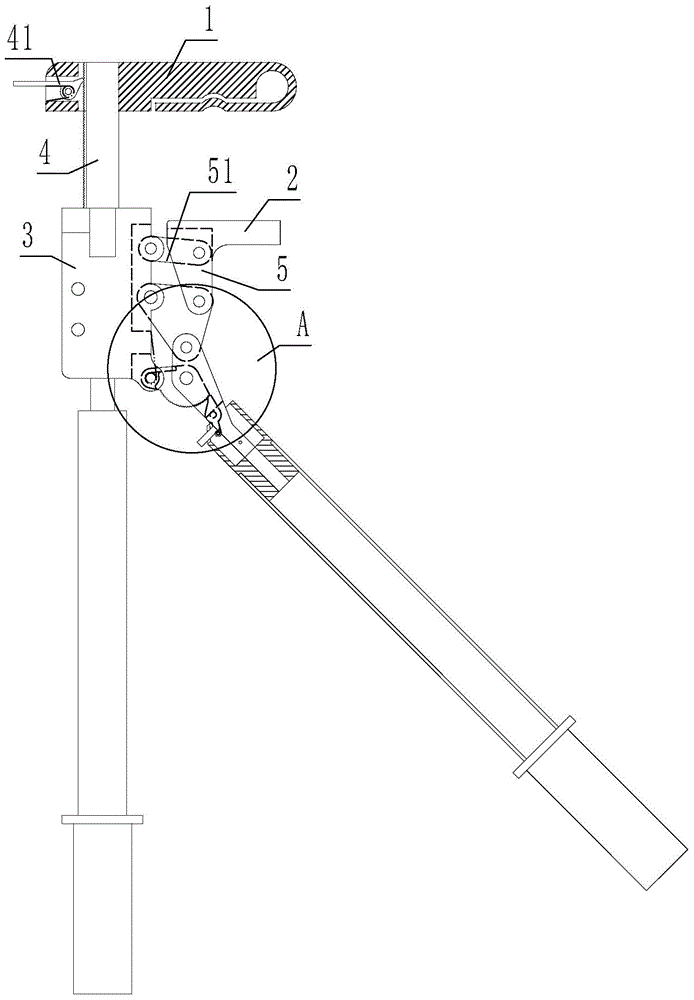

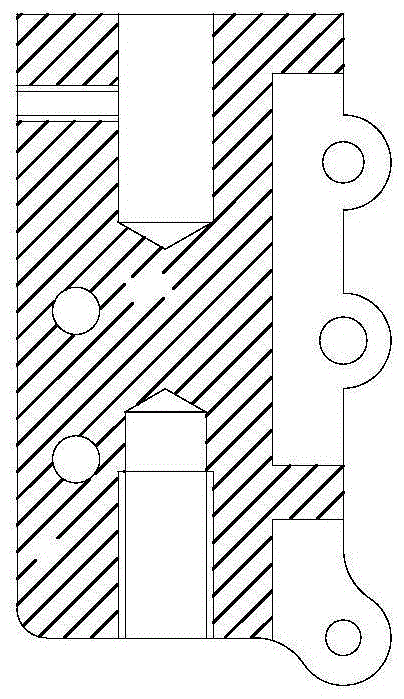

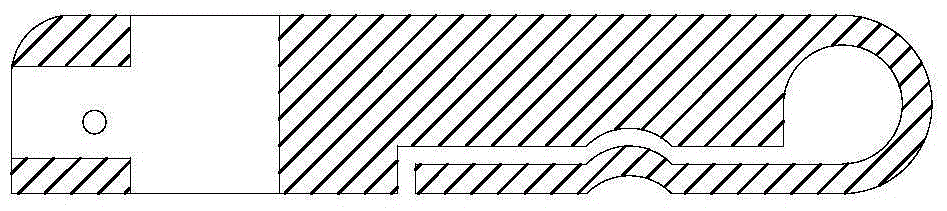

[0029] An automatic clamping device for high-voltage grounding wires, including an upper clamping block 1, a lower clamping block 2, 3 connecting blocks, an upward single-side rack 4 is arranged on the connecting block, and the sawtooth of the single-side rack faces outward , the upper clamping block is worn on the single-side rack, and a claw hole is provided on the side of the upper clamping block that passes through the sawtooth of the single-side rack, and a claw 41 is installed in the claw hole to be connected with the rack. Cooperate to realize the positioning of the two, a six-bar mechanism 5 is provided on the connecting block, and the six-bar mechanism includes three connecting rods 51 and two connecting rods, and the three connecting rods are distributed in the On the connecting block, the first connecting rod, the second connecting rod and the corresponding first connecting rod 52 form a parallelogram motion pair, which drives the first connecting rod to realize reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com