A cable joint insulation plug installation tool and installation method

A technology of cable joints and installation tooling, which is applied in the direction of connection/termination cable equipment, connections, circuits, etc., which can solve problems such as irregularities, inadequate installation of insulating plugs, installation and operation of air gaps, etc., and achieve installation specifications and ingenious design , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

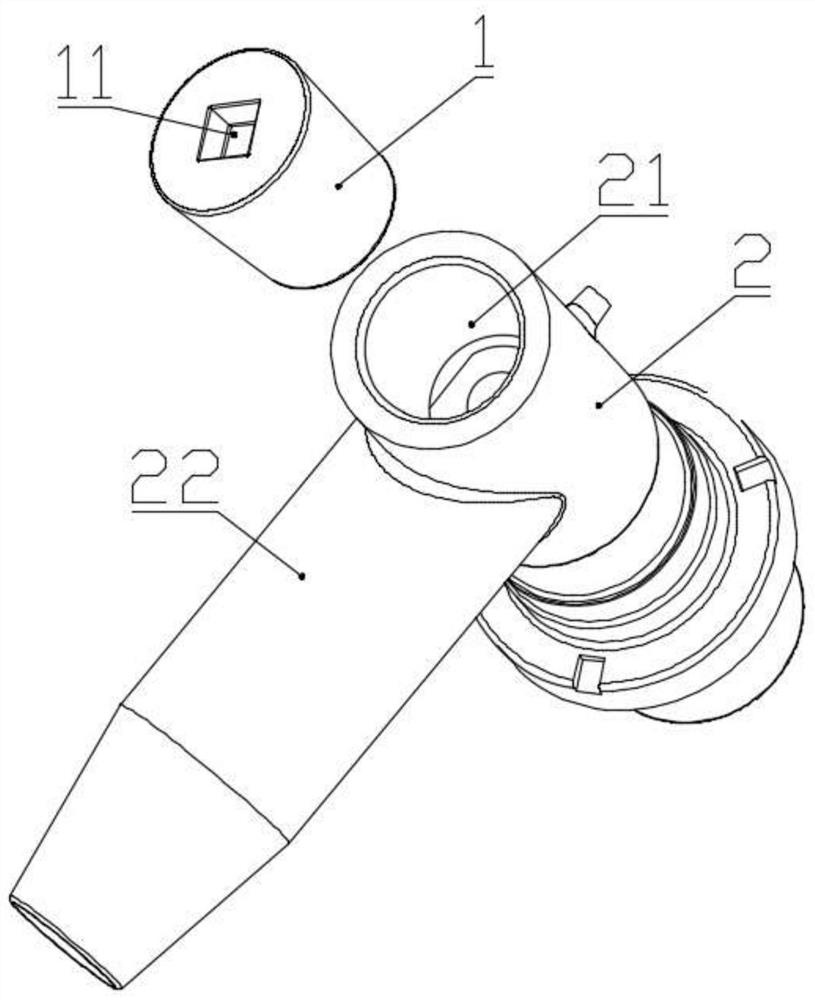

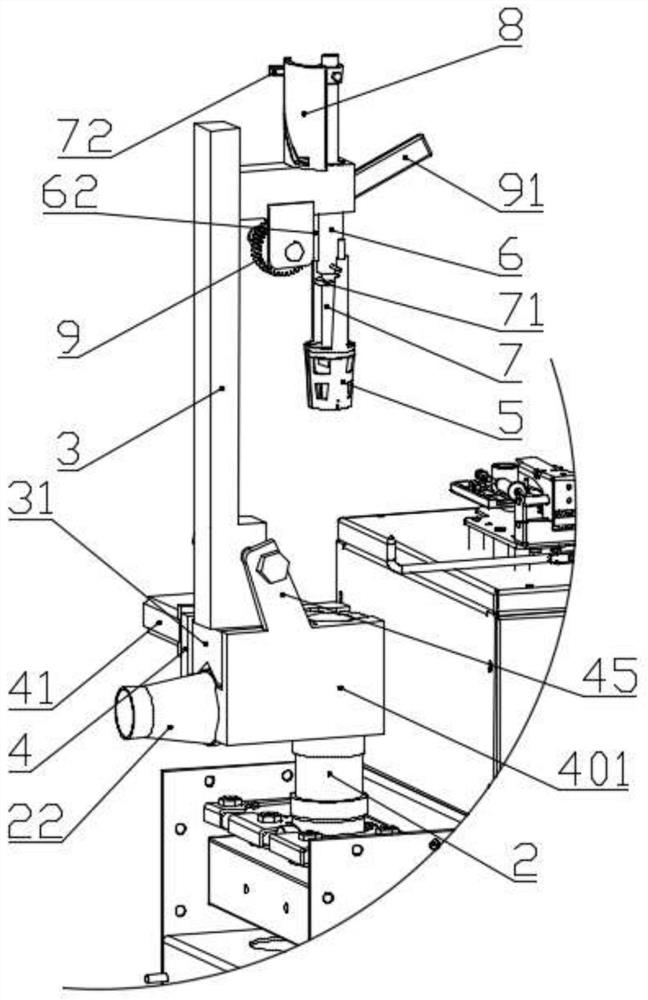

[0050] Such as Figure 2 to Figure 5 As shown: this embodiment discloses a cable joint insulation plug installation tool, including an exhaust tool 5, a bracket 3, a cable joint clamping device connected to the upper end of the bracket 3, and an insulation plug driving device.

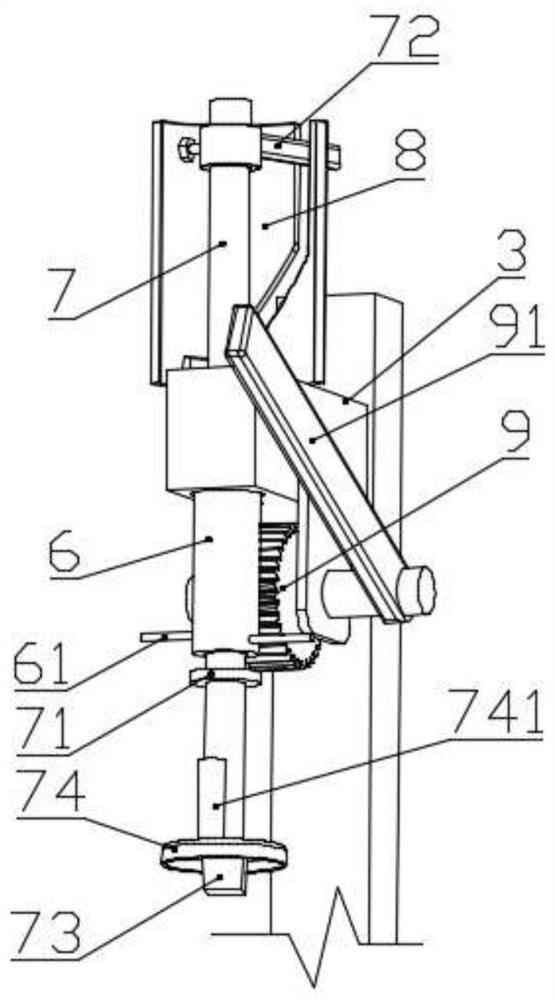

[0051] combine Figure 6 to Figure 8 : Exhaust tooling 5 includes a tapered cylinder 51 with the same taper as the insulating plug and at least two upper extension plates 52 connected to the larger diameter end of the tapered cylinder 51, and the side of the tapered cylinder 51 is provided with a side opening , and the side opening is overlapped and connected by the outer overlapping portion 511 and the inner overlappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com