Vertically-distributed enclosed ink production line

A vertically distributed and closed technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve problems such as ink quality control difficulties, environmental interference pollution, product contamination, etc., to improve production safety factor and control adjustment efficiency , avoid pollution, optimize the effect of the filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

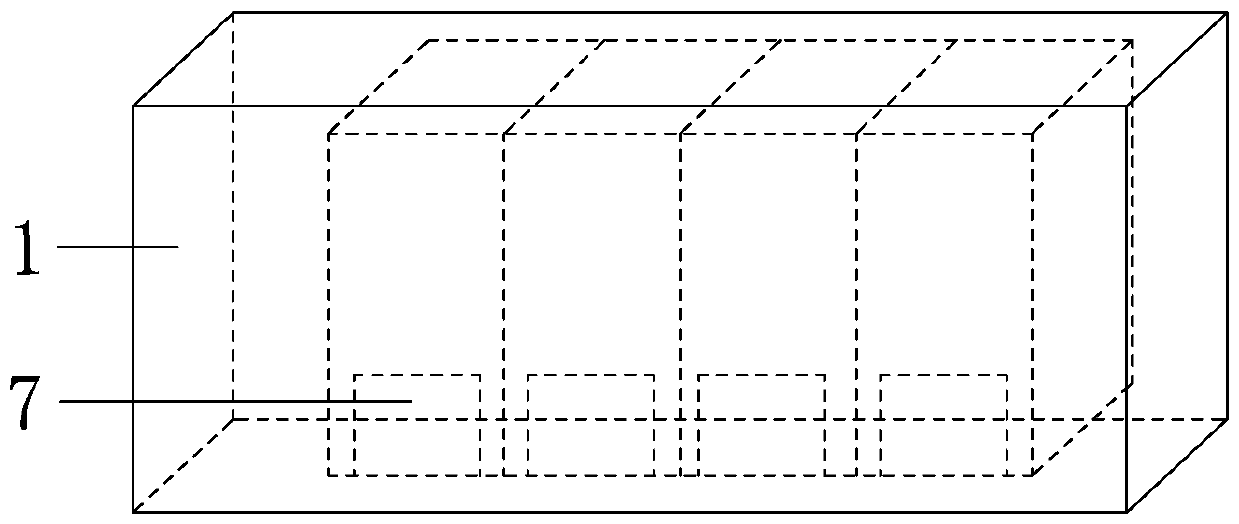

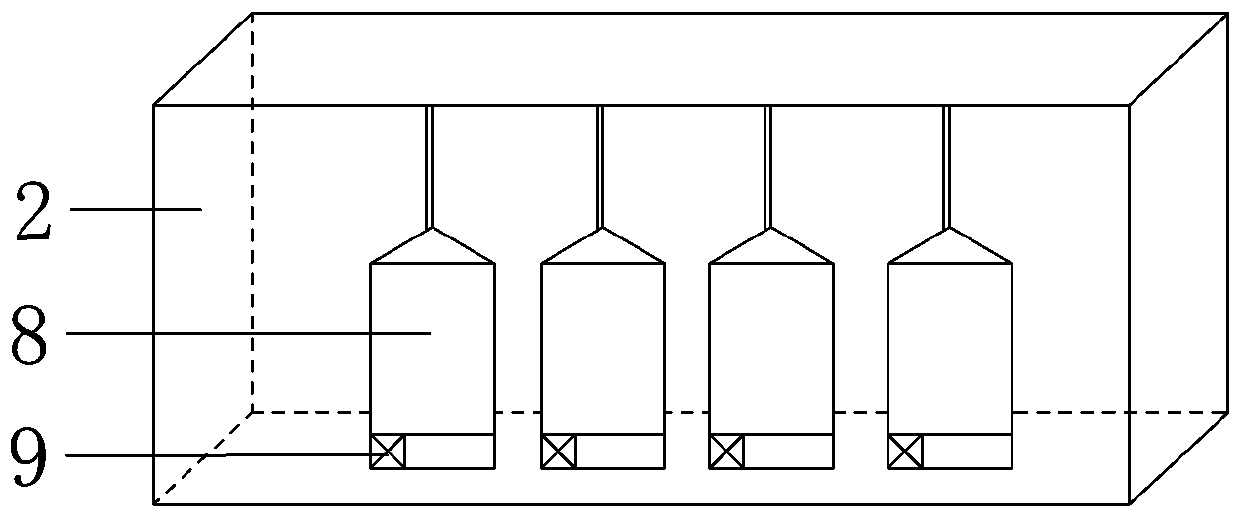

[0034] A vertically distributed closed ink production line, including five units and two systems, namely a feeding unit, a pre-dispersing unit, a grinding unit, an adjustment unit, a filling unit, a closed pipeline system and a monitoring system, the five The units are connected in sequence through the closed pipeline system, and the monitoring system monitors and adjusts the five units.

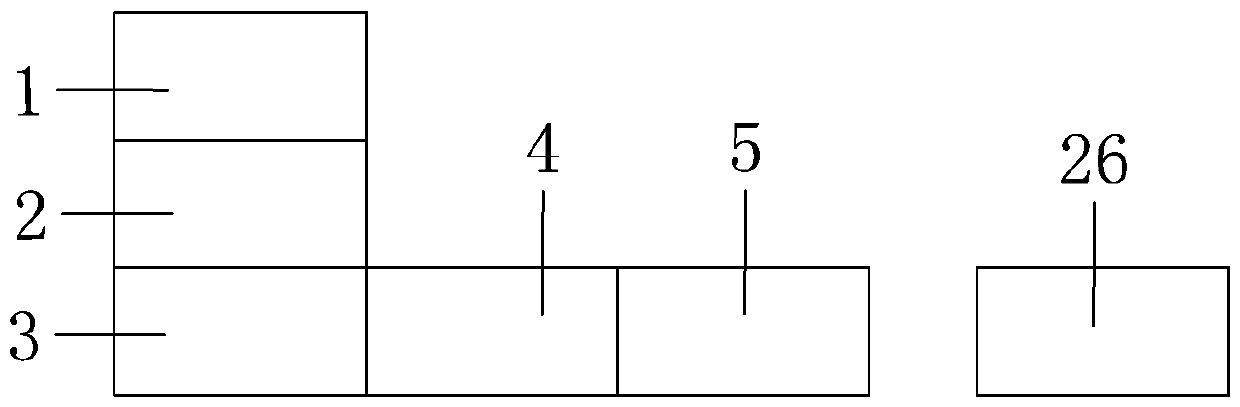

[0035]The closed ink production line is provided with a feeding chamber 1, a pre-dispersion chamber 2, a grinding chamber 3, a material adjustment chamber 4 and a filling chamber 5, which are respectively installed with the feeding unit, pre-dispersion unit, grinding unit, adjustment unit and filling unit. The feeding chamber 1 is arranged on the third floor, the pre-dispersing chamber 2 is arranged on the second floor, the grinding chamber 3, the material adjustment chamber 4 and the filling chamber 5 are arranged on the first floor, the feeding chamber 1, the pre-dispersing chamber The ch...

Embodiment 2

[0049] The difference between Example 2 and Example 1 is that the feeding room is arranged on the fifth floor, the pre-dispersing room is arranged on the fourth floor, the grinding room is arranged on the third floor, the material adjustment room is arranged on the second floor, and the filling room is arranged on the first floor.

[0050] Compared with Example 1, Example 2 can better improve the utilization rate of the production plant in the vertical direction and reduce the single-layer land area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com