Efficient milk foam generating machine

A milk frother and high-efficiency technology, applied in kitchen utensils, home appliances, beverage preparation devices, etc., can solve the problems of slow milk frothing, difficult operation, and time-consuming, and achieve the effect of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

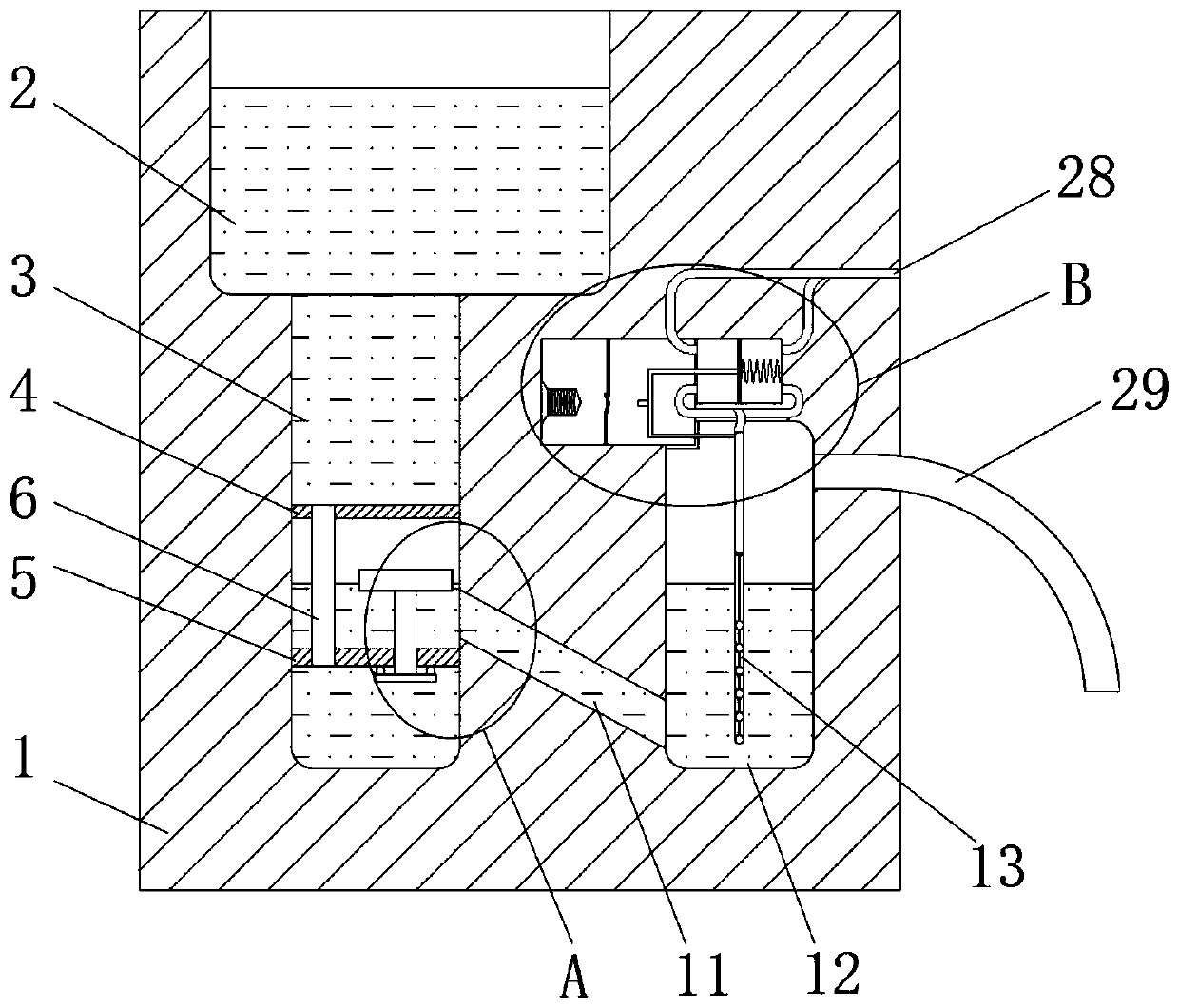

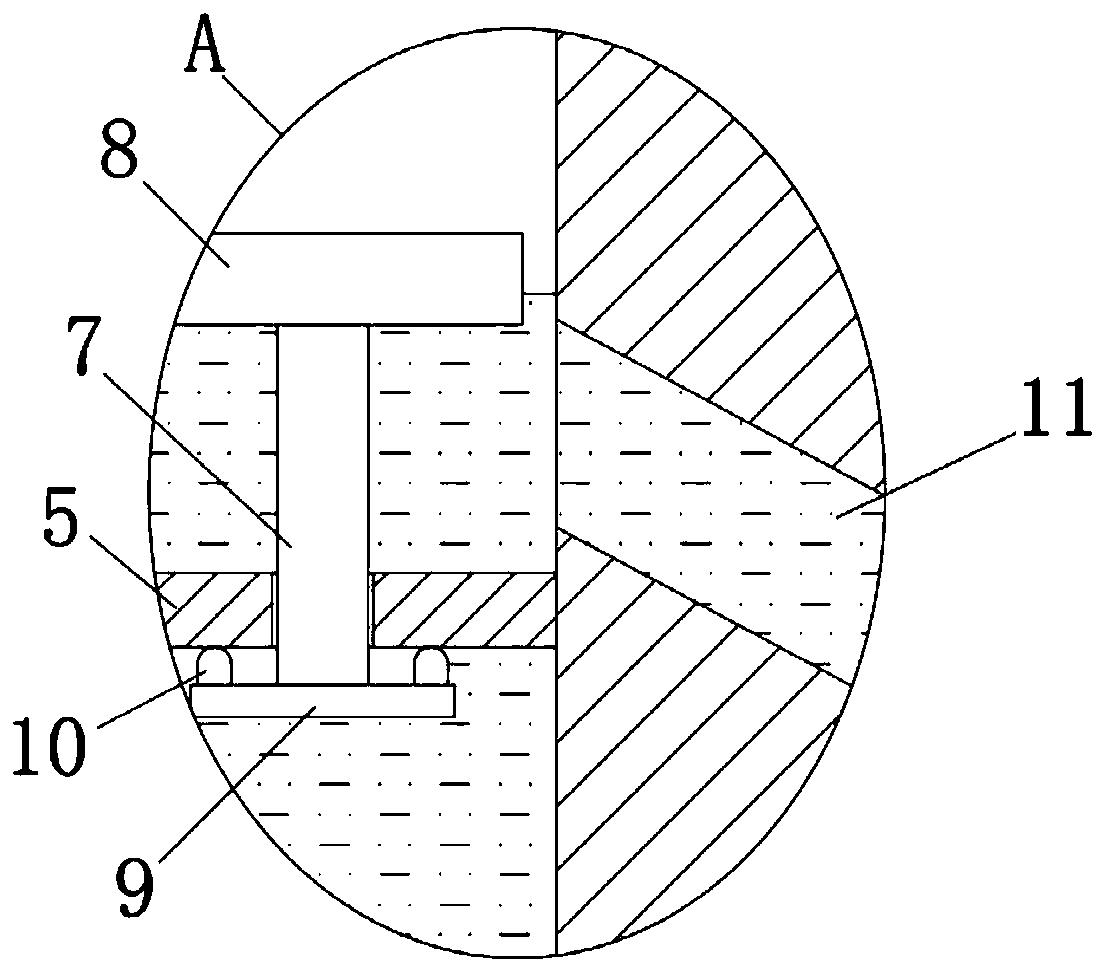

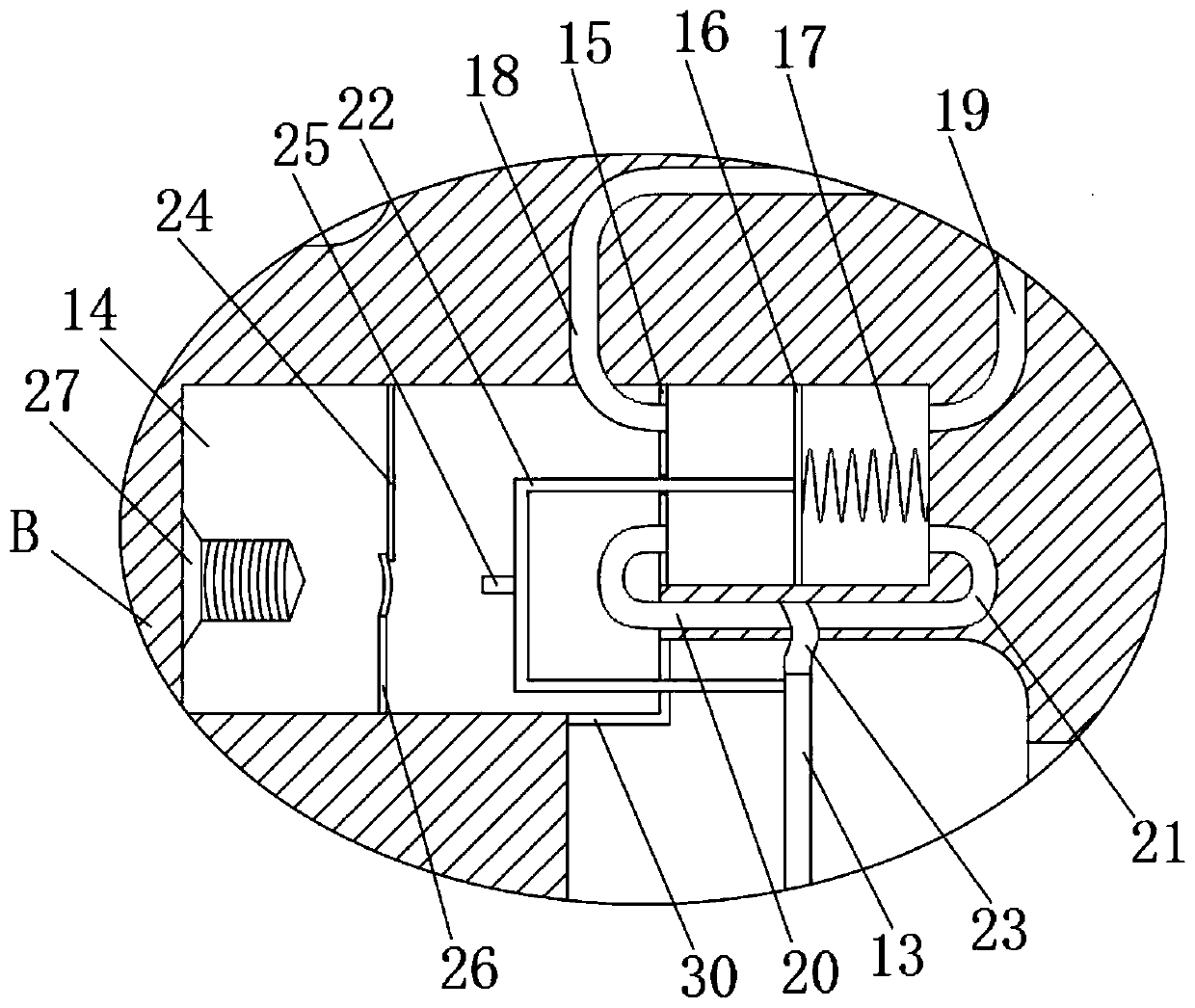

[0023] refer to Figure 1-4 , a high-efficiency milk frother, including a body 1, the body 1 is provided with a milk storage tank 2, a vertical tank 3, a foaming tank 12, and a power chamber 14, and the vertical tank 3 is located at the lower part of the milk storage tank 2 and mutually Connected, the first horizontal plate 4 and the second horizontal plate 5 are fixed in sequence from top to bottom in the vertical pool 3, the first horizontal plate 4 and the second horizontal plate 5 are jointly sealed and communicated with a vertical pipe 6, and the second horizontal plate 5 A round rod 7 is connected slidingly through it, and a floating block 8 is fixed on the end of the round rod 7 close to the first horizontal plate 4, and a circular plate 9 is fixed on the end of the round rod 7 away from the first horizontal plate 4, and the circular plate 9 is close to the first horizontal plate One end of 4 is fixed with a sealing strip 10, and the sealing strip 10 is annularly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com