Integrated granular fuel oolong tea green making system for heat exchange and heat supply channels

A pellet fuel, comprehensive green machine technology, applied in fuel supply, combustion method, combustion equipment and other directions, can solve the problem of not being able to accommodate larger heat exchangers, improve heat exchange efficiency, do not waste heat energy, and save installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

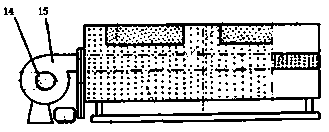

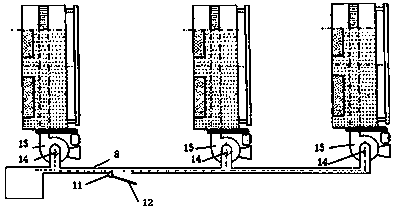

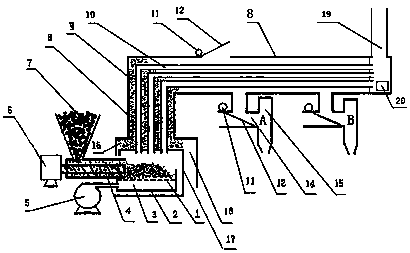

[0018] as attached image 3 The shown heat exchange heat supply channel provided by the present invention is an integrated greening system using granular fuel oolong tea.

[0019] It includes a biomass pellet burner, heat exchange components, heat supply channels and multiple comprehensive greening machines, and is characterized in that: the biomass pellet burner includes a hopper (7), a screw propulsion feeding mechanism (4), a combustion air supply Fan (5), biomass particle combustion hopper (2); the biomass particle combustion hopper (2) is connected with the screw propulsion feeding mechanism (4), and its shape and structure is an L-shaped combustion hopper, and the bottom is provided with a perforated partition ( 1), to facilitate the air intake of the combustion fan, the air intake pressure equalization space is shown in (3); the heat exchange assembly includes an inner cover (17), a plurality of long-spans installed on the inner cover (17) Hot air pipe (10), outer cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com