Lithium battery diaphragm with uniform pore diameter and preparation method thereof

A lithium battery separator and uniform technology, applied in the field of lithium battery separator with uniform pore size and its preparation, can solve the problems of large thickness of multi-layer film, high cost, insufficient polyethylene/polypropylene bonding, etc., and avoid pore size Poor uniformity, good pore size consistency, and the effect of avoiding membrane rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

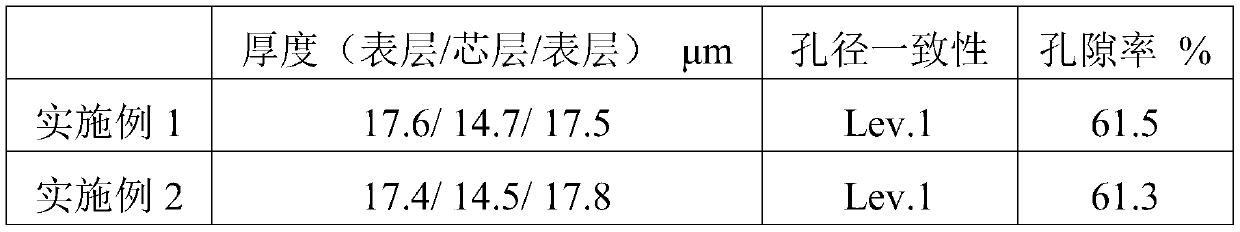

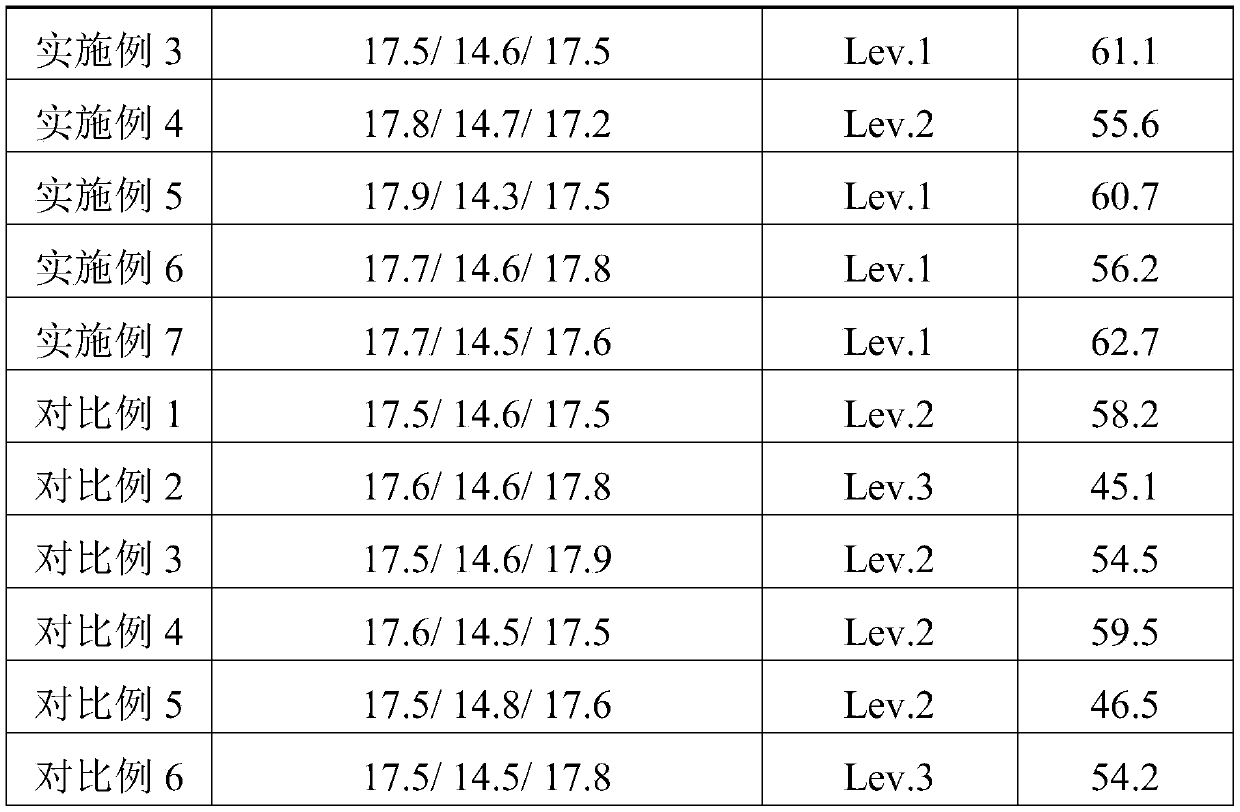

Examples

Embodiment 1

[0044] A lithium battery separator, comprising a core layer and surface layers arranged on both sides of the core layer; the core layer includes 94% polyethylene, 4% epoxy resin, and 2% linear high-density polyethylene; the percentage The content is percentage by weight;

[0045] The surface layer includes 99% polypropylene and 1% polypropylene copolymer; the percentages mentioned are percentages by weight;

[0046] The preparation method of the above-mentioned lithium battery diaphragm comprises the following steps:

[0047] (1) The surface layer and the core layer raw materials are respectively added to the extruder to melt and plasticize, and then cast on the cold drum through a co-extrusion die to form a cast sheet;

[0048] (2) Carrying out heat treatment annealing to cast slab, utilizing 4 heat rollers arranged at intervals to heat up described slab,

[0049] The temperature of the hot roller is 115°C, 117°C, 118°C, 120°C in sequence;

[0050] Then use five cooling ro...

Embodiment 2

[0054] The lithium battery separator provided in Example 1 is different in that the core layer includes 91% polyethylene, 6% epoxy resin, and 3% linear high-density polyethylene; the percentages mentioned are percentages by weight;

[0055] The surface layer includes 98.5% polypropylene and 1.5% polypropylene copolymer; the percentages mentioned are percentages by weight;

[0056] With the rest unchanged, the lithium battery separator was prepared according to the method provided in Example 1.

Embodiment 3

[0058] The lithium battery separator provided in Example 1 is different in that the core layer includes 96.5% polyethylene, 2.5% epoxy resin, and 1% linear high-density polyethylene; the percentages mentioned are percentages by weight;

[0059] The surface layer includes 99.5% polypropylene and 0.5% polypropylene copolymer; the percentages mentioned are percentages by weight;

[0060] With the rest unchanged, the lithium battery separator was prepared according to the method provided in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com