Protective element and circuit protection device thereof

A technology for protection components and circuit protection, applied in the field of protection components, can solve the problems of small cross-sectional area of connecting circuits, inability to conduct heat evenly, and not suitable for large currents, and achieve the effects of improving power, improving reliability, and avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the above and other technical contents, features and advantages of the present invention more comprehensible, the following specifically cites relevant embodiments, together with the accompanying drawings, for a detailed description as follows.

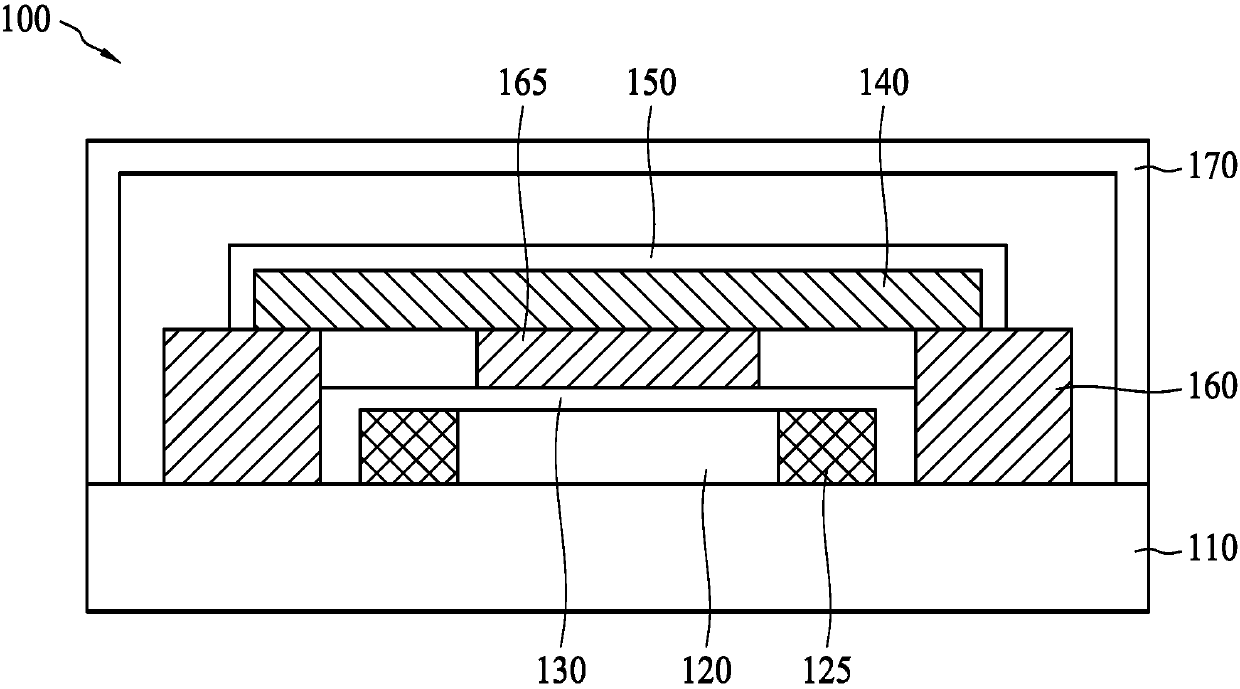

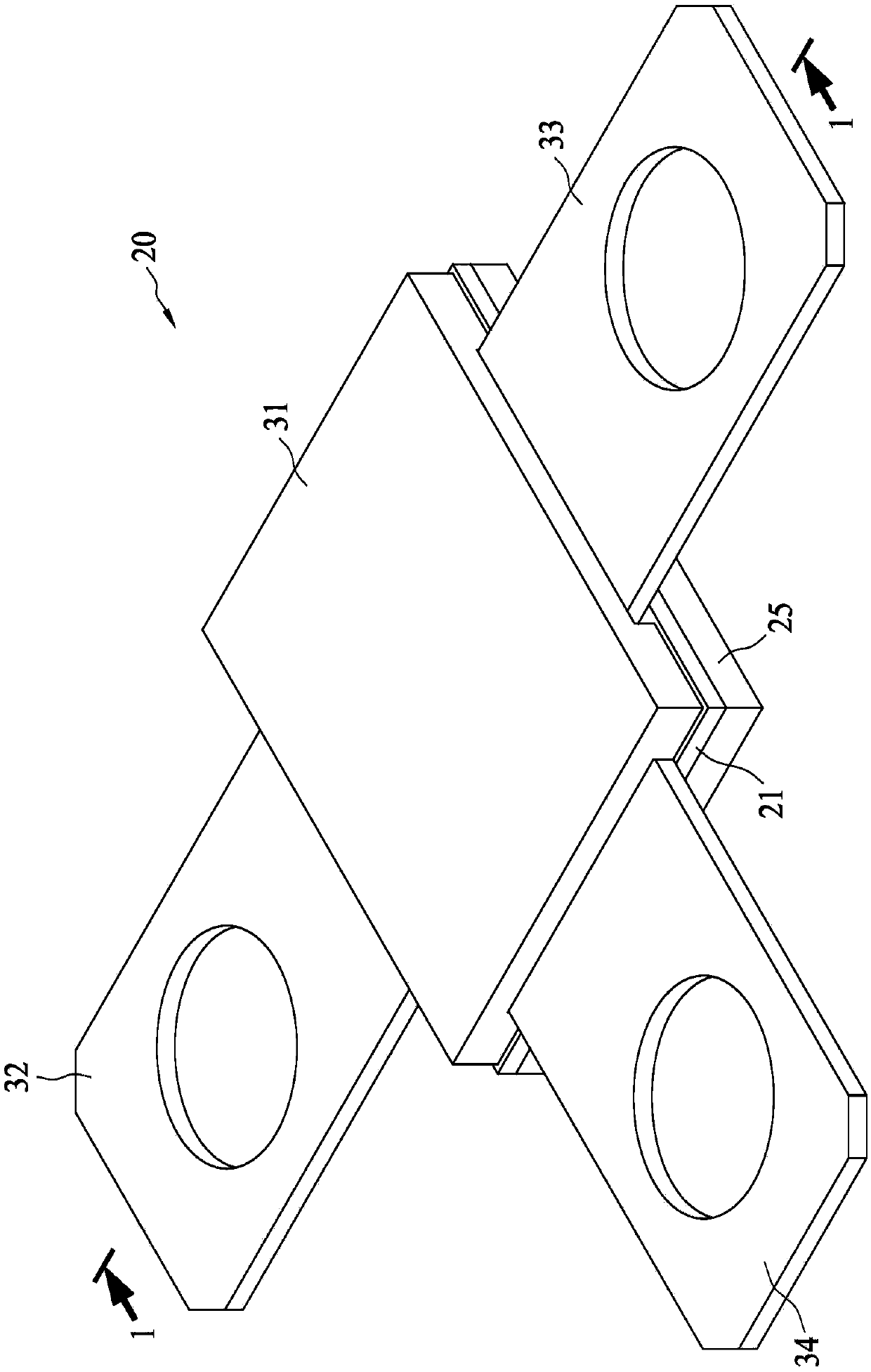

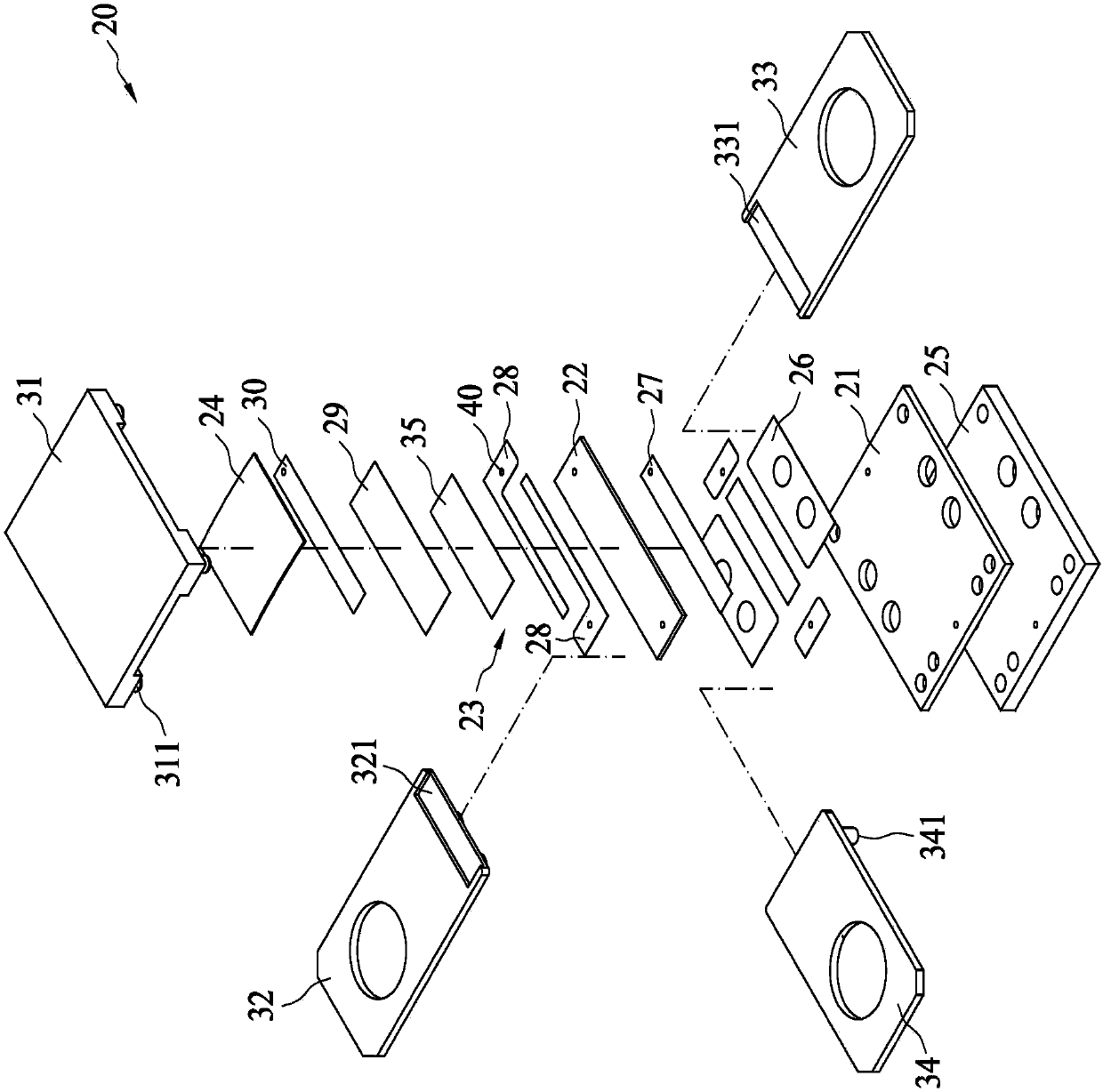

[0060] figure 2 A schematic diagram showing the three-dimensional structure of the protection element 20 according to the first embodiment of the present invention, image 3 is a three-dimensional exploded structural schematic diagram of the protection element 20, Figure 4 then figure 2 A schematic cross-sectional structure diagram of the middle protection element 20 along the section line 1-1. Figure 5It is a schematic diagram of a part of the three-dimensional structure of the protective element 20 without the outer cover 31 . The protection element 20 mainly includes a heating element 23 and a fuse element 24 , wherein when an overvoltage or an overtemperature occurs, the heating element 23 generates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com