Constant-temperature bath for working viscosity liquid setting value

A technology of viscosity liquid and constant temperature bath, applied in the field of constant temperature bath, can solve the problems of temperature accuracy, uniformity, poor stability, etc., to achieve the effect of improving uniformity and stability, great promotion value, and ensuring temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

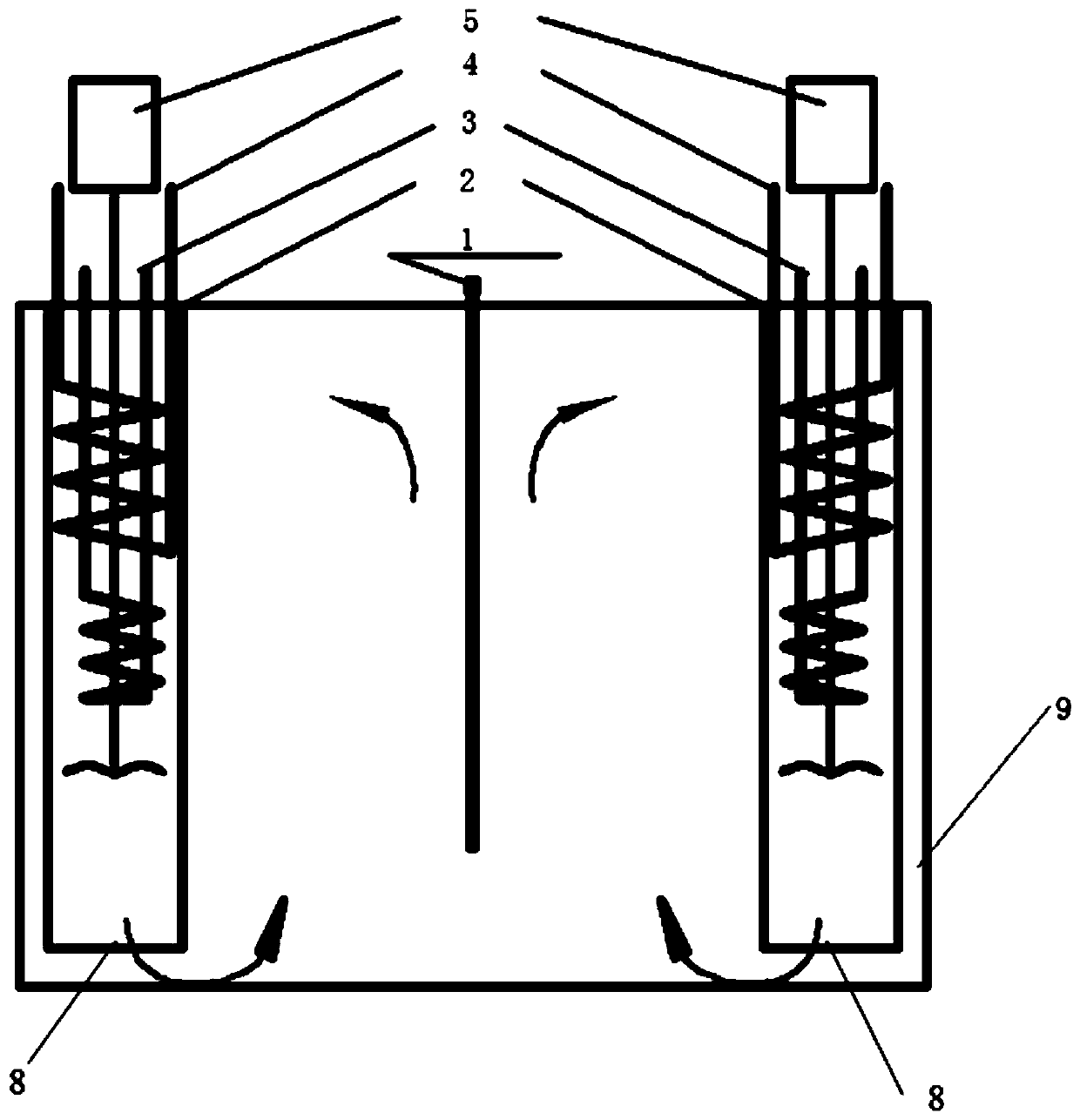

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The structure of the constant temperature tank, the thermal inertia of the system, the uniform heating of the medium, the good flow state of the mixture and the reliability of the whole machine all directly affect the constant temperature effect of the constant temperature tank. Considering the hardware, the constant temperature effect of the constant temperature tank is related to the internal shape of the tank body. When the shape of the tank body is a sphere, the temperature is the most uniform and the constant temperature effect is the best. In order to meet the requirement of simultaneous verification / calibration of 6 working capillary viscometers and the monitoring of the entire verification / calibration process with an industrial camera, if the thermostatic bath is designed as a spherical or cylindrical body, the cost of other funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com