Novel pin tumbler lock cylinder capable of avoiding technical opening

A technology of technical opening and tumbler, which is applied in the field of new anti-technical opening tumbler lock cylinder, which can solve the problems of poor anti-theft and achieve the effect of increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

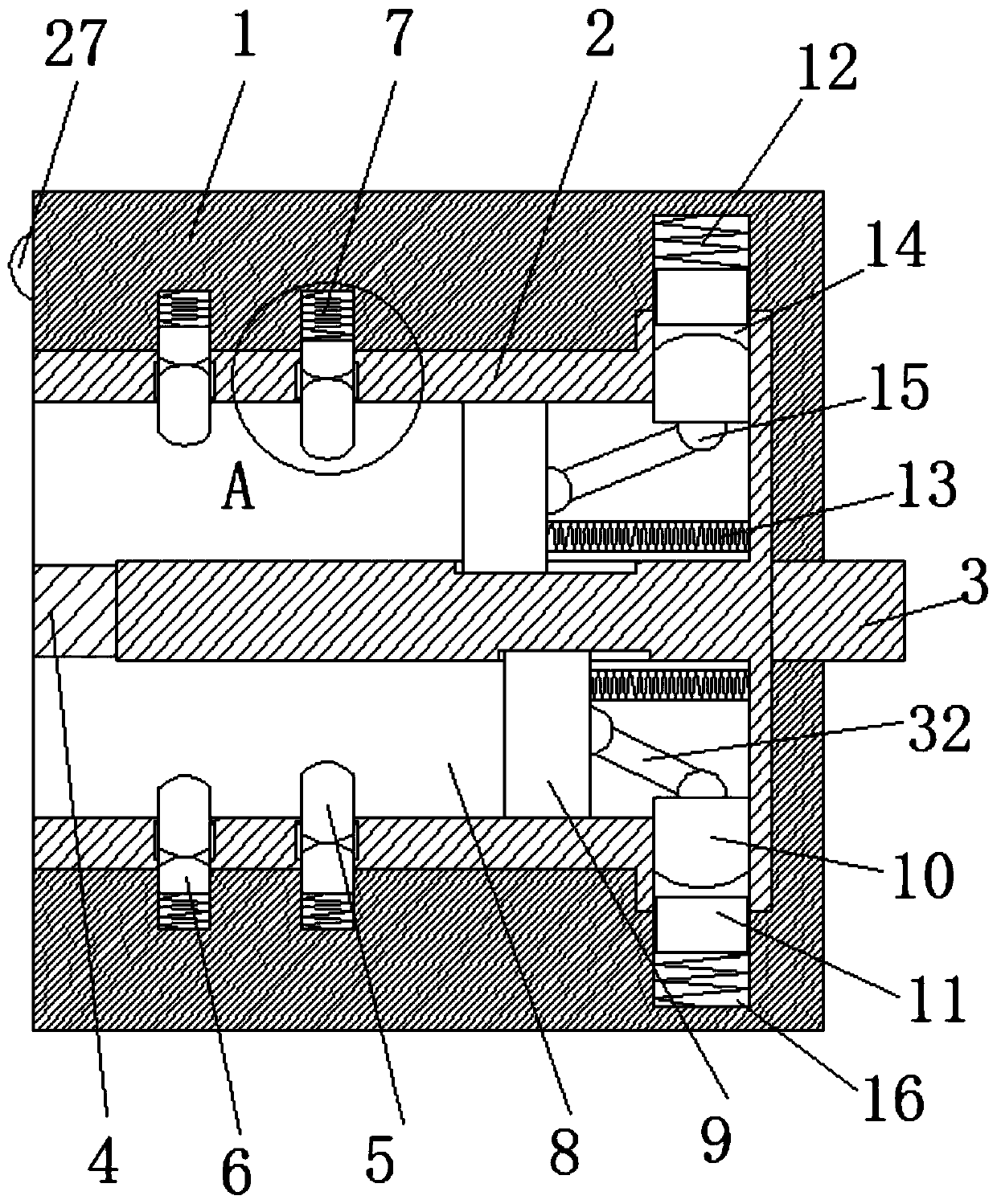

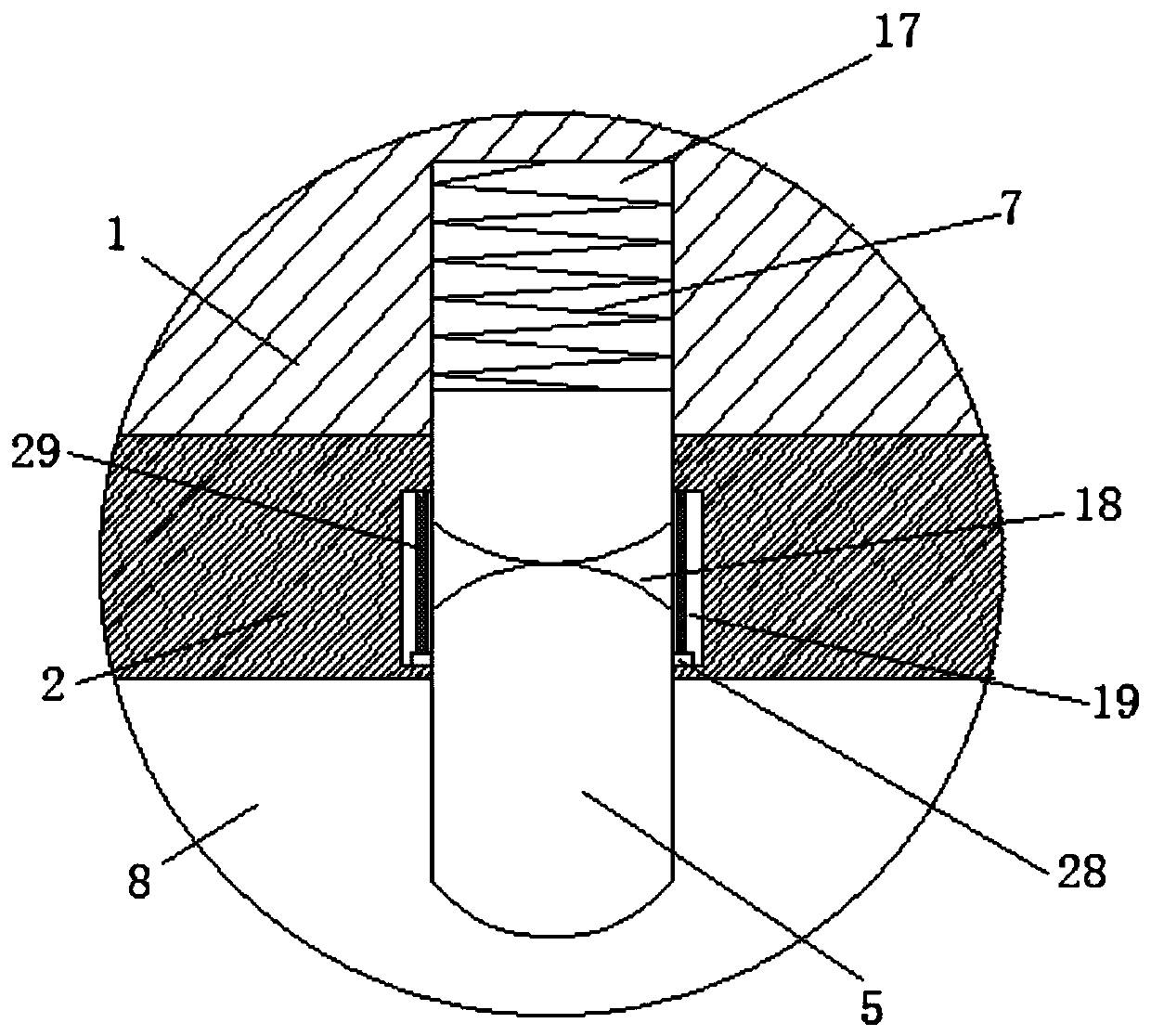

[0033] Embodiment 1, a new anti-technical opening tumbler lock cylinder, including a lock body 1, a lock cylinder 2, a lock rod 3 and a key 20, the lock body 1 is provided with a rotatable lock cylinder 2, and the lock cylinder 2 The middle part is provided with a fixedly connected lock bar 3, the lock bar 3 passes through the outside of the lock body 1, and the lock core 2 positioned outside the lock bar 3 is provided with a number of evenly distributed lock holes 8;

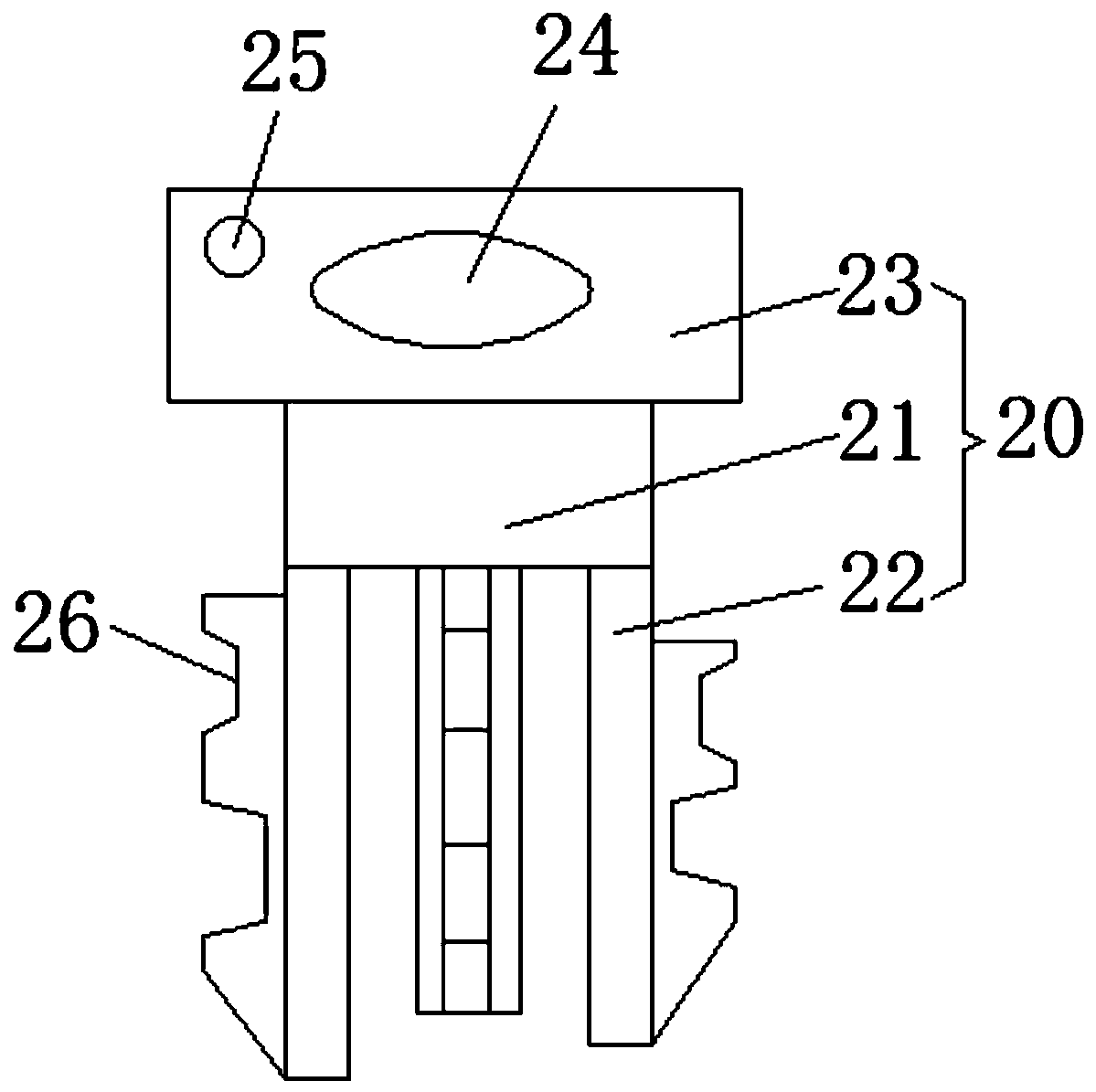

[0034] The key 20 is composed of a handle 23, a key body 21 and a key shaft 22. The bottom of the key body 21 is provided with a number of evenly distributed key shafts 22 that match the lockhole 8. The outside of the key shaft 22 is provided with a number of uniform Distributed key slots 26.

[0035] Preferably, a handle frame 24 is provided in the middle of the handle 23 , and a first protrusion 25 is provided on the handle 23 , and a corresponding second protrusion 27 is provided on the outer surface of the ...

Embodiment 2

[0051] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0052] The first upper pin 6 and the first spring 17 are not provided in one or more of the first upper bullet slots 18 . The first springs and the first upper pins in the corresponding one or more first upper bullet slots in different lock holes are removed, thereby forming a similar " "False first pin", so that the unlocker cannot accurately determine the exact position of the "false first pin". When using technology to open, push the "false first pin" to the misplaced position, which will push the "false first pin". "One click" into the first upper bullet slot, thereby locking the lock cylinder and locking cylinder, increasing the difficulty of anti-technical opening, and setting a fourth spring in the corresponding first lower bullet slot to connect with the adjustment rod, using the fourth spring Increase the damping of the "false first pinch" when pushing to confuse the ope...

Embodiment 3

[0054] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0055] At the bottom of one or more of the locking holes 9, the second lower bullet slot 14 and the second lower pin 10 are no longer provided, and the corresponding second upper bullet slot 16 and second upper pin 11 are removed at the same time. Remove the second lower bullet groove and the second lower pin at the bottom of one or more lock holes, and remove the corresponding second upper bullet groove and second upper pin at the same time, thus forming one or more "false pressing blocks" , so that the unlocker cannot accurately determine the exact position of the "false pressing block", which further increases the difficulty of preventing technical opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com