Thermal treating processing method of spring stop rings and special tempering tool of thermal treating processing method

A spring retaining ring and processing method technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as brittle fracture, reduce deformation, ensure product quality, and improve flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

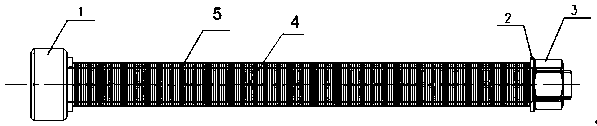

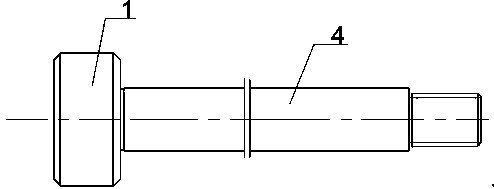

[0027] Step 1, cleaning the formed retaining ring 5 to be processed to remove stains and oil stains on the surface;

[0028] Step 2. String the cleaned spring retaining ring 5 to be processed with thin iron wires. In order to avoid uneven quenching and ensure that each surface of the part is evenly exposed to the quenching medium, there are multiple knots on the iron wires. Use nodules (knots) The adjacent spring retaining rings are separated by the middle tie; then put into the vacuum quenching material frame, and send it into the vacuum quenching furnace for quenching. The quenching process adopts the heating method of preheating and quenching, and the vacuum quenching furnace is vacuumized before heating. , the vacuum degree is kept at 13.3Pa. After 25 minutes from room temperature, the equipment is heated to a preheating temperature of 660°C, kept for 25 minutes, and then the equipment is heated to a quenching temperature of 860°C after 15 minutes.

[0029] Step 3. Send th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com