Conductive polymer composite material under the action of magnetic field and preparation method thereof

A technology of conductive polymer and composite material, which is applied to the field of conductive polymer composite material and its preparation under the action of a magnetic field, can solve the problem that the conductive performance of the conductive polymer composite material needs to be further improved, and achieves simple operation, improved compatibility, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the first aspect of the present invention, an embodiment of the present invention provides a method for preparing a conductive polymer composite material under the action of a magnetic field, comprising the following steps:

[0028] (1) Take 0.1-0.3g of nickel powder and pyrrole monomer, add 30-50mL of ethanol aqueous solution and 0.1-0.3g of sodium chloride, stir evenly, and then energize pyrrole to polymerize, and obtain polypyrrole-coated nickel particles after purification, wherein, The molar ratio of nickel powder to pyrrole monomer is (1:1)-(1:3), and the ethanol aqueous solution is obtained by mixing water and ethanol with a volume ratio of (1:1)-(1:3);

[0029] (2) After mixing polyurethane acrylate resin, diethylene glycol monovinyl ether, 2-hydroxyl-2-methylpropiophenone and the polypyrrole-coated nickel particles, place them in a magnetic field with a strength of 0.01-0.03T In the magnetic field, the urethane acrylate resin is cured with ultravio...

Embodiment 1

[0048] Embodiment 1: Prepare conductive polymer composite material with polyurethane acrylate resin and polypyrrole-coated nickel particles

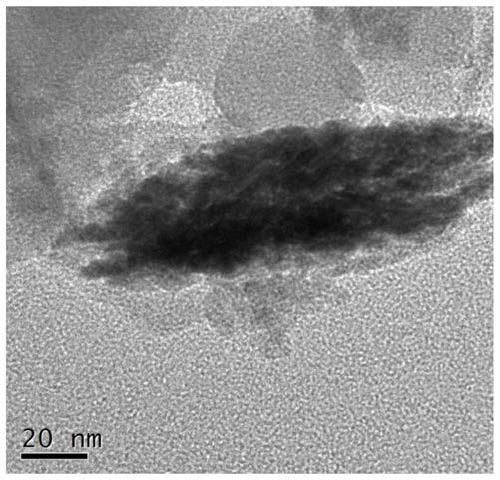

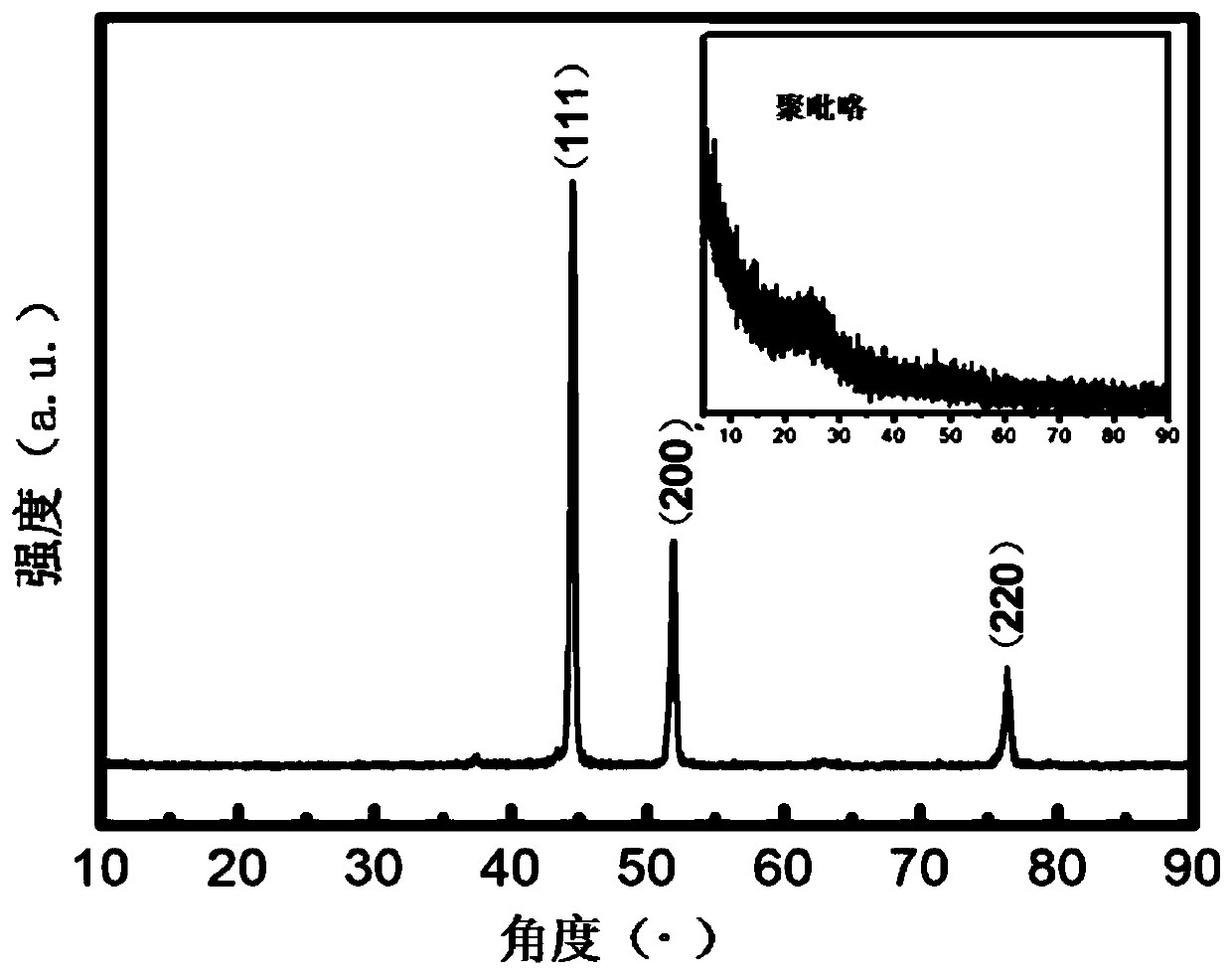

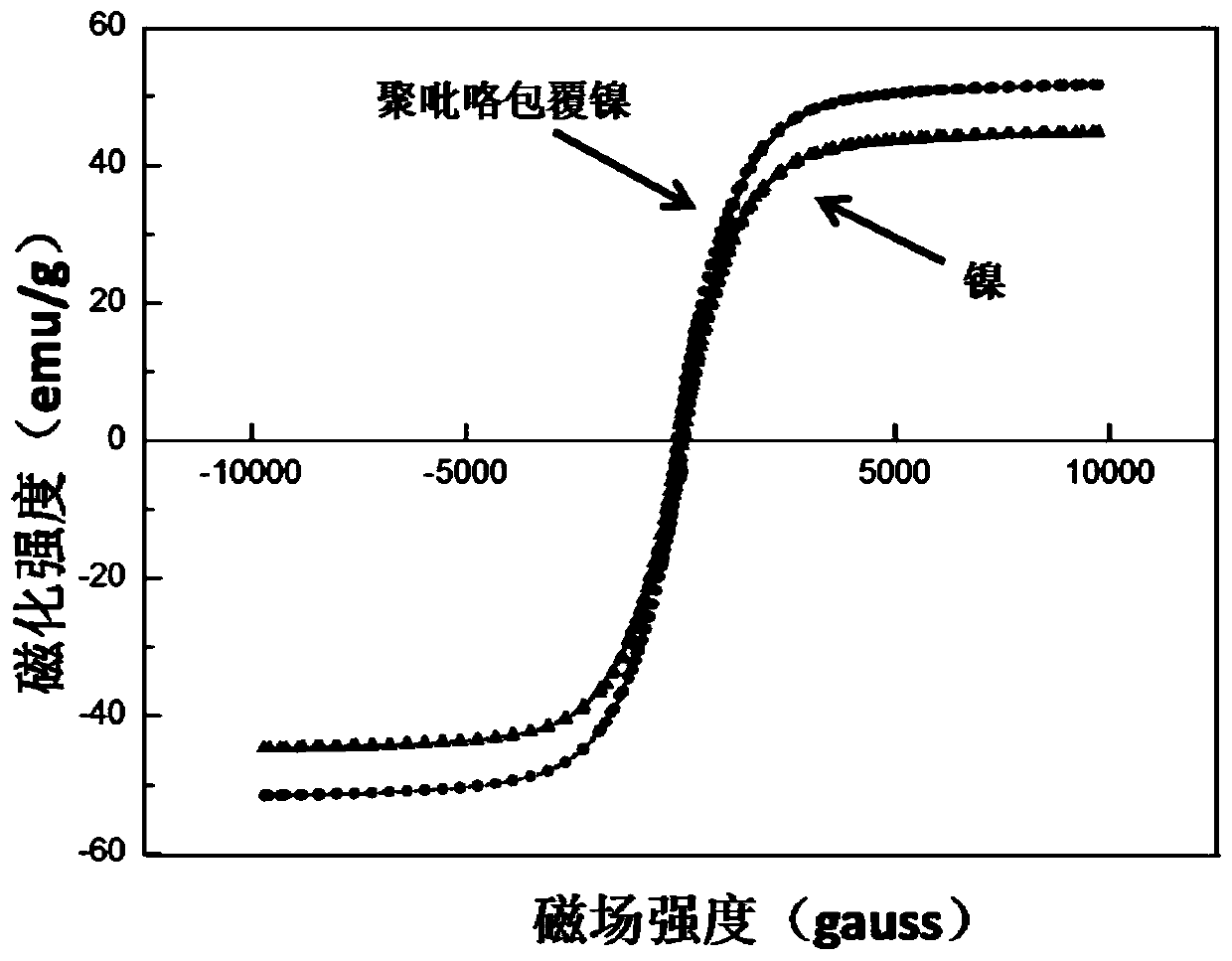

[0049] (1) Put nickel powder with a particle size of 0.1-1mm and pyrrole monomer in a molar ratio of 1:1. Take 0.3g of nickel powder and pyrrole monomer in a beaker, add 50mL of ethanol aqueous solution with a volume ratio of water and ethanol of 1:1 , and then add 0.2g of sodium chloride, stir evenly and the current density is 2.0mA·cm -2 Direct current for 10 minutes, take out the composite material, add ethanol and centrifuge, take the solid and place it in an oven at 80°C to dry to obtain polypyrrole-coated nickel particles.

[0050](2) Get 3g polyurethane acrylate resin in the beaker, then take the quality of polyurethane acrylic resin as a benchmark, add 10% diethylene glycol monovinyl ether, 5% 2-hydroxyl-2-methylpropiophenone, 1 % of the polypyrrole-coated nickel particles prepared in step (1), stirred evenly, placed in a magnet...

Embodiment 2

[0057] Example 2: Preparation of conductive polymer composite material with polyurethane acrylate resin and polypyrrole-coated nickel particles

[0058] (1) Put nickel particles with a particle size of 0.1-1mm and pyrrole monomer in a molar ratio of 1:3 to take 0.3g of nickel powder and pyrrole monomer in a beaker, add 50mL of ethanol aqueous solution with a volume ratio of water and ethanol of 1:1 , and then add 0.2g of sodium chloride, stir evenly and the current density is 2.0mA·cm -2 Direct current for 10 minutes, take out the composite material, add ethanol and centrifuge, take the solid and place it in an oven at 80°C to dry to obtain polypyrrole-coated nickel particles.

[0059] (2) Get 3g polyurethane acrylate resin in the beaker, then take the quality of polyurethane acrylic resin as a benchmark, add 10% diethylene glycol monovinyl ether, 5% 2-hydroxyl-2-methylpropiophenone, 1 % of polypyrrole-coated nickel particles prepared in the first step, stirred evenly, placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com